Improved coupling medium supply of an ultrasonic test device

A technology for coupling media and inspection devices, applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, measurement devices, reduction of greenhouse gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

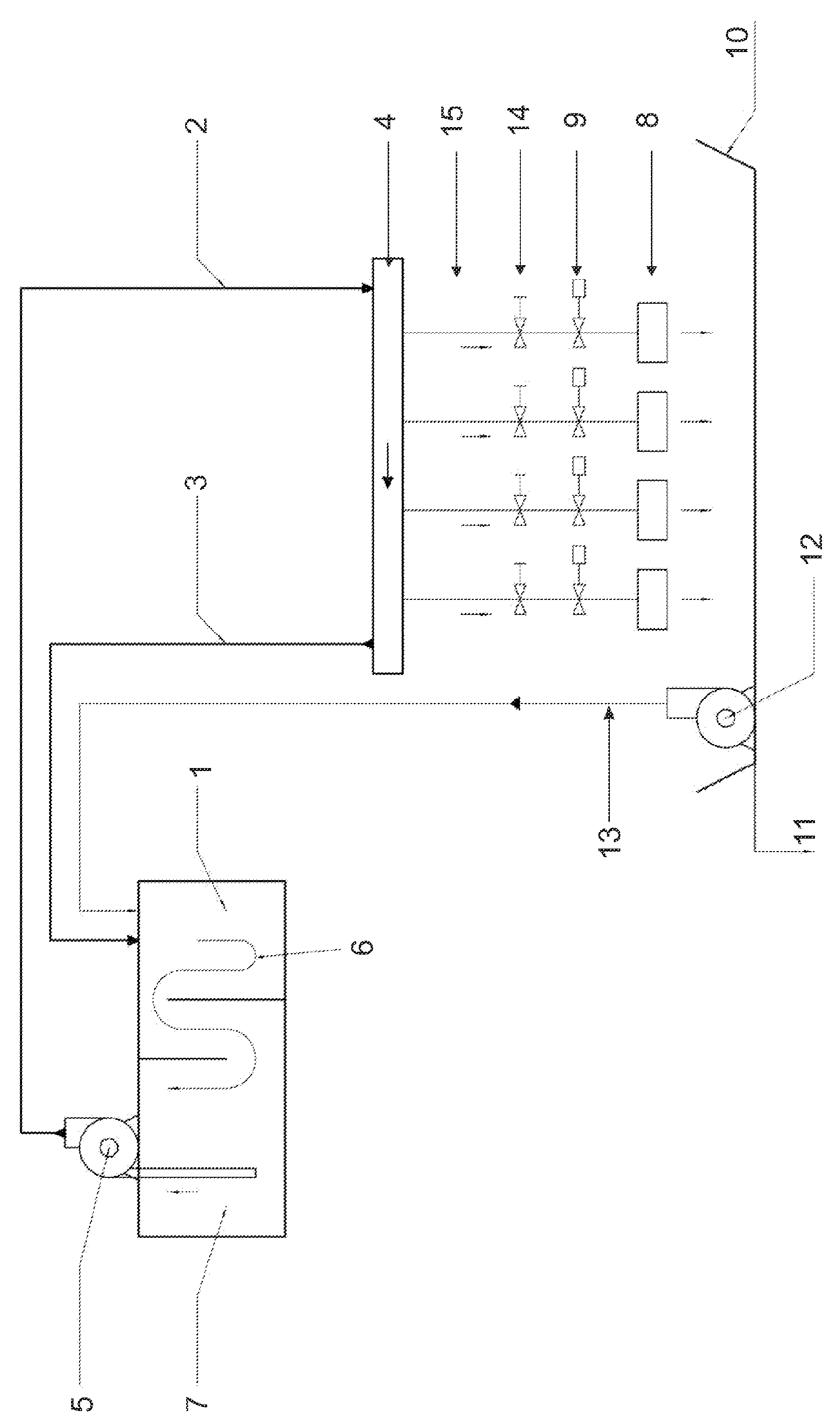

[0032] figure 1 In an advantageous embodiment, the method according to the invention is shown schematically, wherein substantially only the components provided for the supply of the coupling medium are shown, and for the sake of clarity, apart from the test head, no one provided for the ultrasonic examination is shown. Components and related test objects. A coupling medium (preferably natural water) is used for the acoustic coupling between the associated test head 8 and the object to be examined by means of ultrasound and is conveyed into a coupling chamber provided for this purpose, not shown in detail . The supply of the coupling medium according to the invention provides for a continuous circulation of the coupling medium. This cycle can be performed during and / or prior to the ultrasonic inspection. The forced circulation in the embodiment shown is effected via lines 2 , 3 and distributor 4 , settling tank 1 and pump 5 . Here, a settling tank 1 for degassing the coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com