Acrylic acid modified nitro anti-corrosion lacquer and preparation method thereof

An acrylic and anti-corrosion paint technology, applied in anti-corrosion coatings, coatings, etc., to achieve excellent weather resistance, good use effect, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An acrylic modified nitro anticorrosion paint, comprising the following components, by weight (g),

[0039] Acrylic nitro paste 30 Nitro lacquer exterior materials 55

[0040] 1% silicone oil butyl acetate solution 0.01;

[0041] Wherein: the acrylic nitro pulp contains the following components, by weight (g):

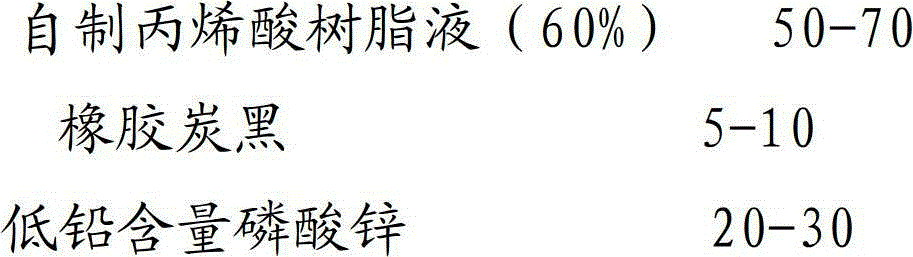

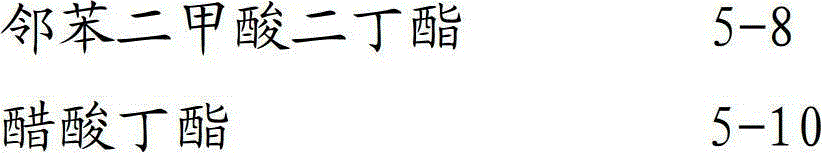

[0042]

[0043] The exterior material for nitro lacquer contains the following components, by weight (g):

[0044] 1 / 2 second nitrocellulose solution (26%) 60

[0045] 30 seconds nitrocellulose solution (11%) 20

[0046] Mixed solvent 5;

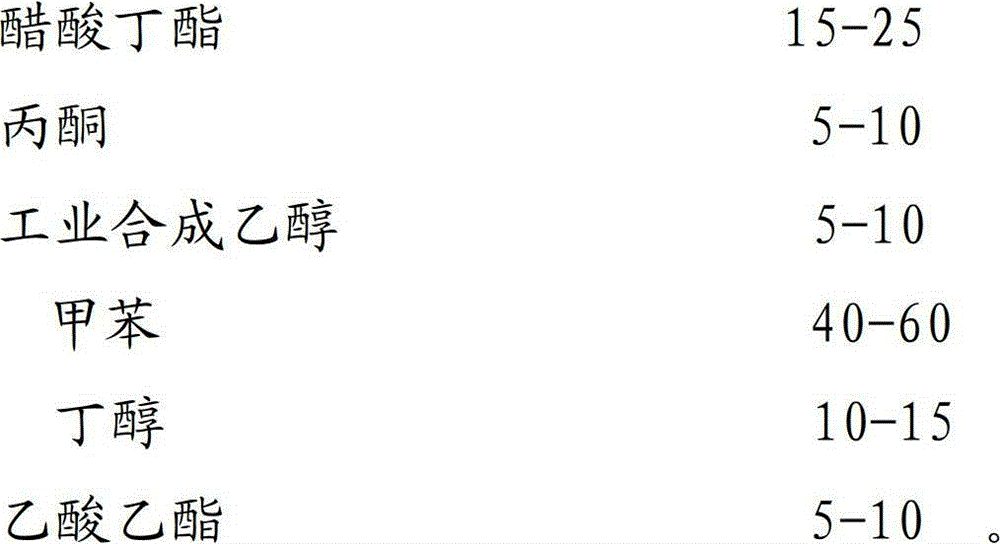

[0047] The mixed solvent contains the following components, by weight (g):

[0048]

[0049]

[0050] A kind of preparation method of acrylic acid modified nitro anticorrosion paint, carries out according to the following steps:

[0051] (1) Preparation of acrylic nitro pulp:

[0052] Add self-made acrylic resin liquid (60%), butyl acetate and dibutyl phthalate into the batching tank and stir evenly, then add r...

Embodiment 2

[0062] An acrylic modified nitro anticorrosion paint, comprising the following components, by weight (g),

[0063] Acrylic nitro pulp 45 Nitro lacquer exterior materials 70

[0064] 1% silicone oil butyl acetate solution 0.02;

[0065] Wherein: the acrylic nitro pulp contains the following components, by weight (g):

[0066]

[0067] The exterior material for nitro lacquer contains the following components, by weight (g):

[0068] 1 / 2 second nitrocellulose solution (26%) 70

[0069] 30 seconds nitrocellulose solution (11%) 35

[0070] Mixed solvent 10;

[0071] The mixed solvent contains the following components, by weight (g):

[0072]

[0073] The preparation method of acrylic acid modified nitro anticorrosion paint is carried out according to the first step of the embodiment.

Embodiment 3

[0075] An acrylic modified nitro anticorrosion paint, comprising the following components, by weight (g),

[0076] Acrylic nitro paste 35 Nitro lacquer exterior materials 65

[0077] 1% silicone oil butyl acetate solution 0.01;

[0078] Wherein: the acrylic nitro pulp contains the following components, by weight (g):

[0079]

[0080] The exterior material for nitro lacquer contains the following components, by weight (g):

[0081] 1 / 2 second nitrocellulose solution (26%) 65

[0082] 30 seconds nitrocellulose solution (11%) 30

[0083] Mixed solvent 8;

[0084] The mixed solvent contains the following components, by weight (g):

[0085]

[0086] The preparation method of acrylic acid modified nitro anticorrosion paint is carried out according to the first step of the embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com