riveted connection structure

A riveting and structuring technology, applied in the direction of connection, conductive connection, vehicle connector, etc., can solve the problems of easy fracture, reduced reliability, insufficient strength, etc., and achieve the effect of preventing fracture, improving mechanical strength, and preventing insufficient strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

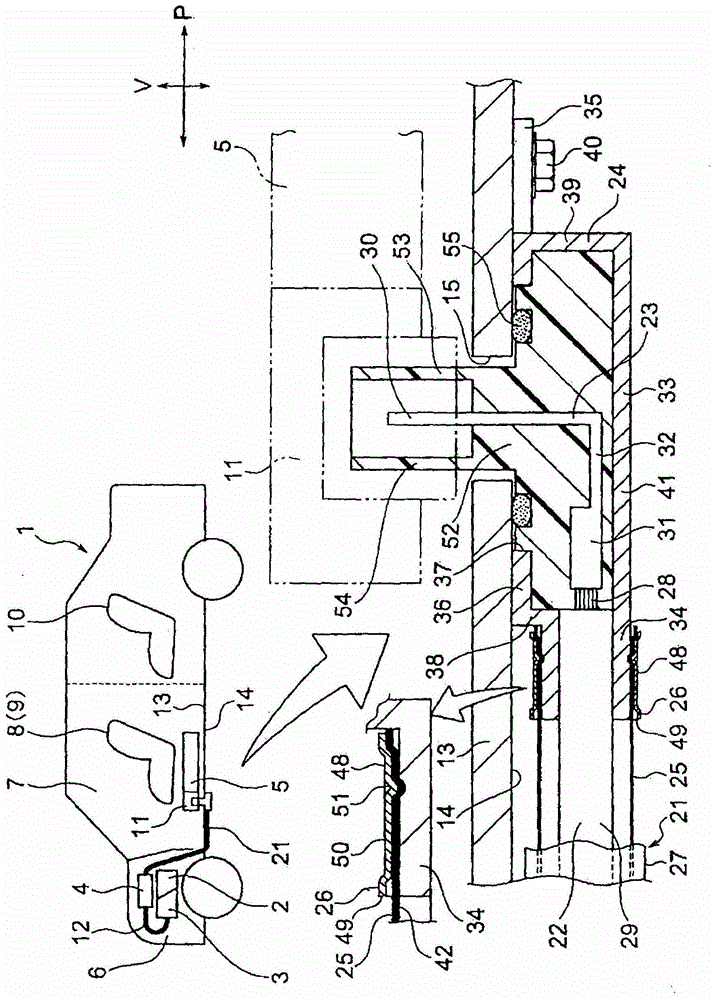

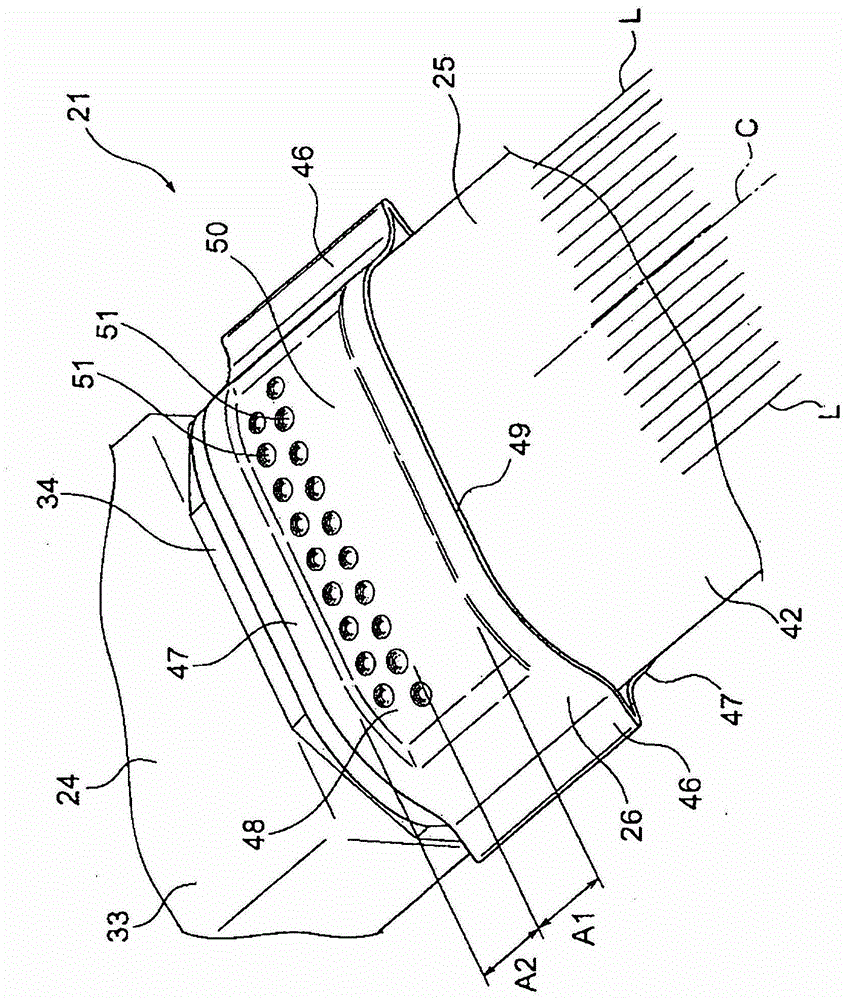

[0038] Next, Embodiment 1 will be described with reference to the drawings. figure 1 It is a schematic diagram of an automobile including the riveted connection structure of the present invention and an enlarged cross-sectional view of main parts. in addition, figure 2 is included figure 1 A perspective view of the terminal part of the riveted connection structure of the harness, image 3 It is a sectional view showing the structure of a cylindrical metal foil member.

[0039] The wire harness described later in this embodiment is intended to be a wire harness wired in a hybrid vehicle or an electric vehicle. Hereinafter, an example of a hybrid car will be given for description (in the case of an electric car, the structure, structure and effect of the wiring harness of the present invention are basically the same. In addition, it is not limited to a hybrid car or an electric car, and ordinary cars, etc. can also application of the present invention).

[0040] figure 1 In...

Embodiment 2

[0072] Next, Embodiment 2 will be described with reference to the drawings. Figure 4 It is a perspective view of the terminal part including the crimp connection structure which becomes another example of this invention. in addition, Figure 5 is included Figure 4 The model diagram of the car with the riveted connection structure and the enlarged cross-sectional view of the main part, Figure 6 It is a perspective view of a caulking connection structure as a comparative example. In addition, the same reference numerals are assigned to the same components as in the first embodiment described above, and detailed description thereof will be omitted.

[0073] exist Figure 4 as well as Figure 5 Among them, the caulking portion 61 formed by crushing the upper and lower portions 47 is formed by deforming the annular caulking member 26 inward in two stages. In addition, it is formed by deforming so as not to generate an edge like the peripheral edge portion 49 . That is, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com