Apparatus and method for frame crimping

A handheld device and portable device technology, applied in the direction of metal processing equipment, etc., can solve the problems of large equipment, high initial cost and high operating cost, and not easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

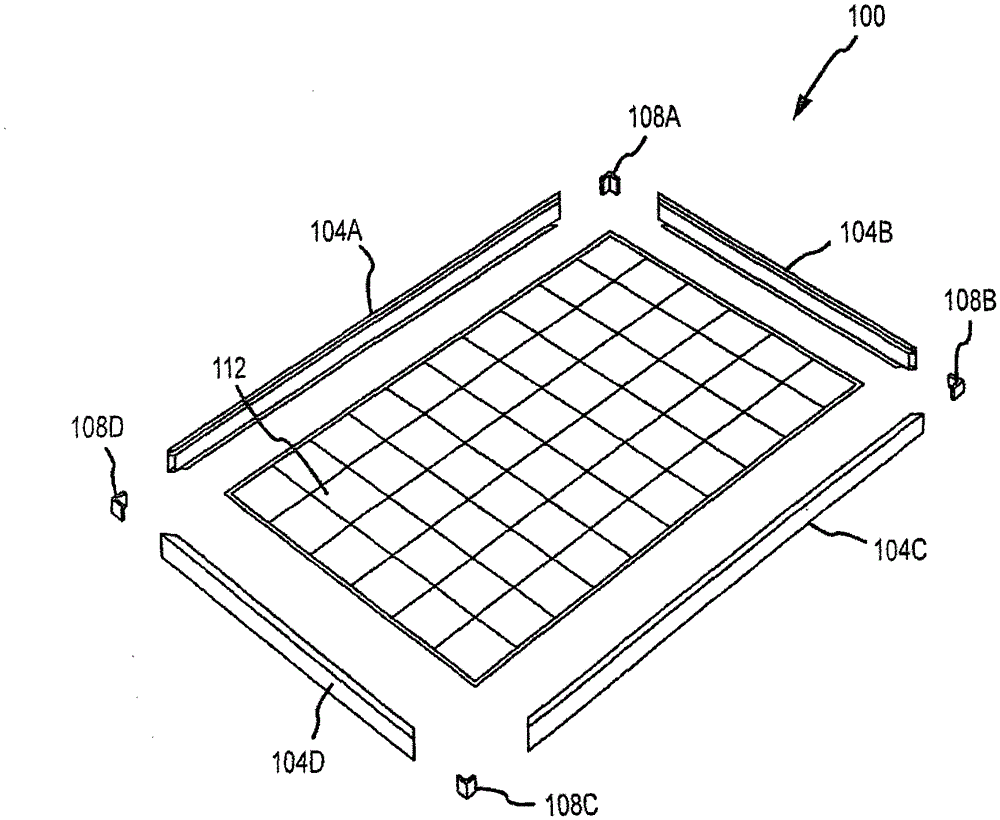

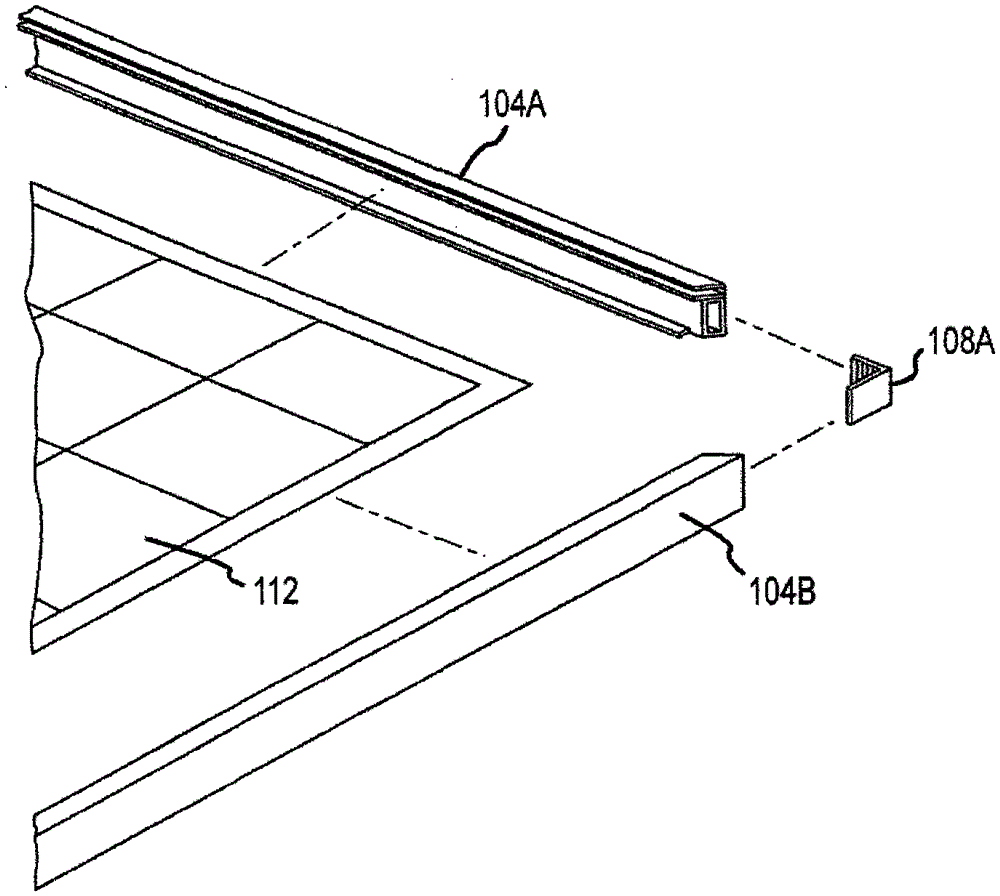

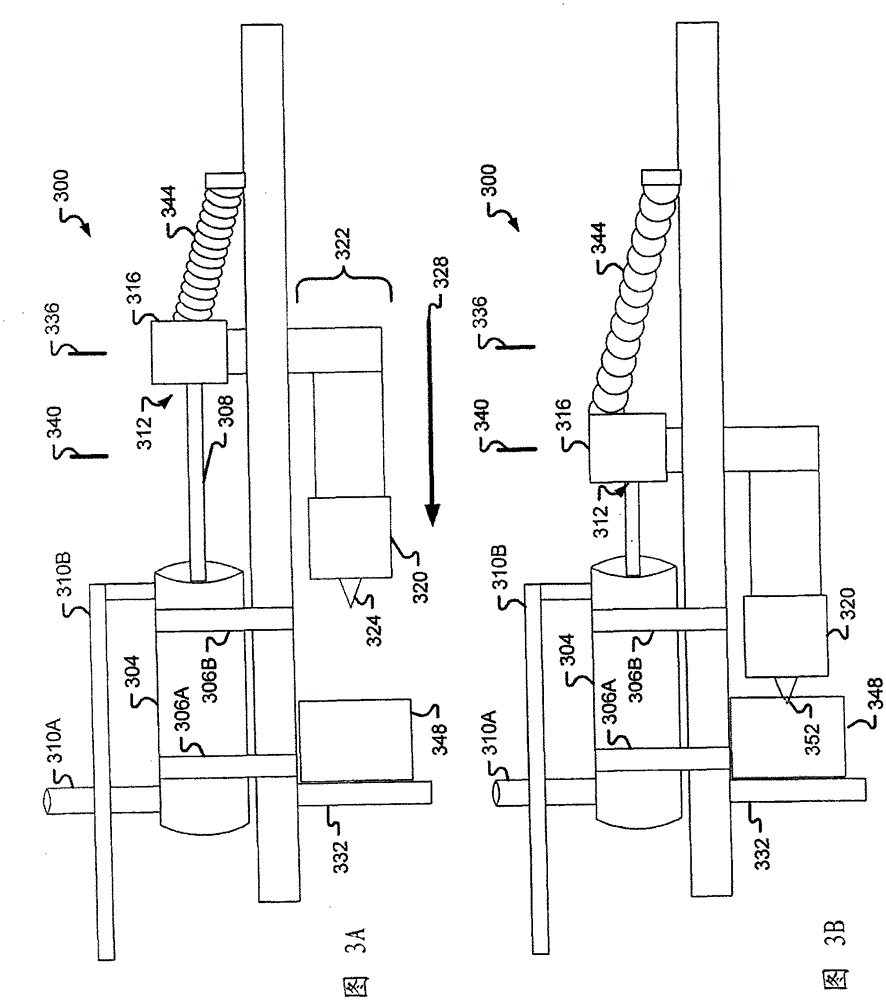

[0027] Presented here is an embodiment of the device. The device in embodiments is a portable crimping device, in some embodiments hand-held, so that it can be easily moved from one location to another, including moving to a new or previously used crimping device to be repaired or replaced. The field position of the frame. The device may include a stem movable from a first position to a second position. a head is connected to the stem, a spike is connected to the head, the spike engages a rail of the frame when the stem moves from the first position to the second position, and deform a portion of the rail to secure the L-shaped key, such as a bracket in the channel of the rail. A second rail may then be fastened to the second side of the L-shaped key, creating a corner of the frame. The above process can be repeated to produce a closed frame for supporting eg flat photovoltaic panels or photovoltaic glass.

[0028] Embodiments of the present invention overcome some of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com