Synthetic method of ethylene glycol monoallyl ether

A technology of propylene ether and ethylene glycol monolayer, applied in the field of fine chemicals, can solve the problems of difficult separation, recycling and reuse of catalysts, wide product distribution, equipment corrosion, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

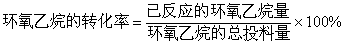

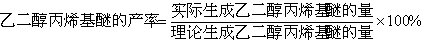

[0027] Example 1

[0028] Add 5.01g of catalyst and 290g of propylene alcohol into a reaction kettle with a volume of 2L, seal it, stir, and raise the temperature. When the temperature reaches 80°C, stop heating, and continue to introduce 44g of ethylene oxide into the reaction kettle. At this time, propylene alcohol The molar ratio to ethylene oxide is 5:1, the pressure inside the reactor is controlled to be 0.2~0.4MPa, and the reaction temperature is kept constant at 80°C by adjusting the amount of water passed into the cooling coil of the reactor. After the reaction, the conversion rate of ethylene oxide was 76.44%, and the yield of ethylene glycol monopropenyl ether was 67.29%.

Example Embodiment

[0029] Example 2

[0030] Add 5.01g of catalyst and 290g of propylene alcohol into a reaction kettle with a volume of 2L, seal it, stir, and raise the temperature. When the temperature reaches 90°C, stop heating, and continue to introduce 44g of ethylene oxide into the reaction kettle. At this time, propylene alcohol The molar ratio to ethylene oxide is 5:1, the pressure inside the reactor is controlled to be 0.2~0.4MPa, and the reaction temperature is kept constant at 90°C by adjusting the amount of water passed into the cooling coil of the reactor. After the reaction, the conversion rate of ethylene oxide was 89.68%, and the yield of ethylene glycol monopropenyl ether was 77.44%.

Example Embodiment

[0031] Example 3

[0032] Add 5.01g of catalyst and 290g of propylene alcohol into a reaction kettle with a volume of 2L, seal it, stir, and raise the temperature. When the temperature reaches 100°C, stop heating, and continue to introduce 44g of ethylene oxide into the reaction kettle. At this time, propylene alcohol The molar ratio to ethylene oxide is 5:1, the pressure inside the reactor is controlled at 0.2~0.4MPa, and the reaction temperature is kept constant at 100°C by adjusting the amount of water passed into the cooling coil of the reactor. After the reaction, the conversion rate of ethylene oxide was 97.46%, and the yield of ethylene glycol monopropenyl ether was 81.50%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap