Water gas transfer reaction, water gas transfer catalyst, and method of preparing water gas transfer catalyst

A technology of water gas and catalyst, which is applied in the field of catalysts used in water gas shift reaction, and can solve the problems such as the decline of carbon monoxide conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

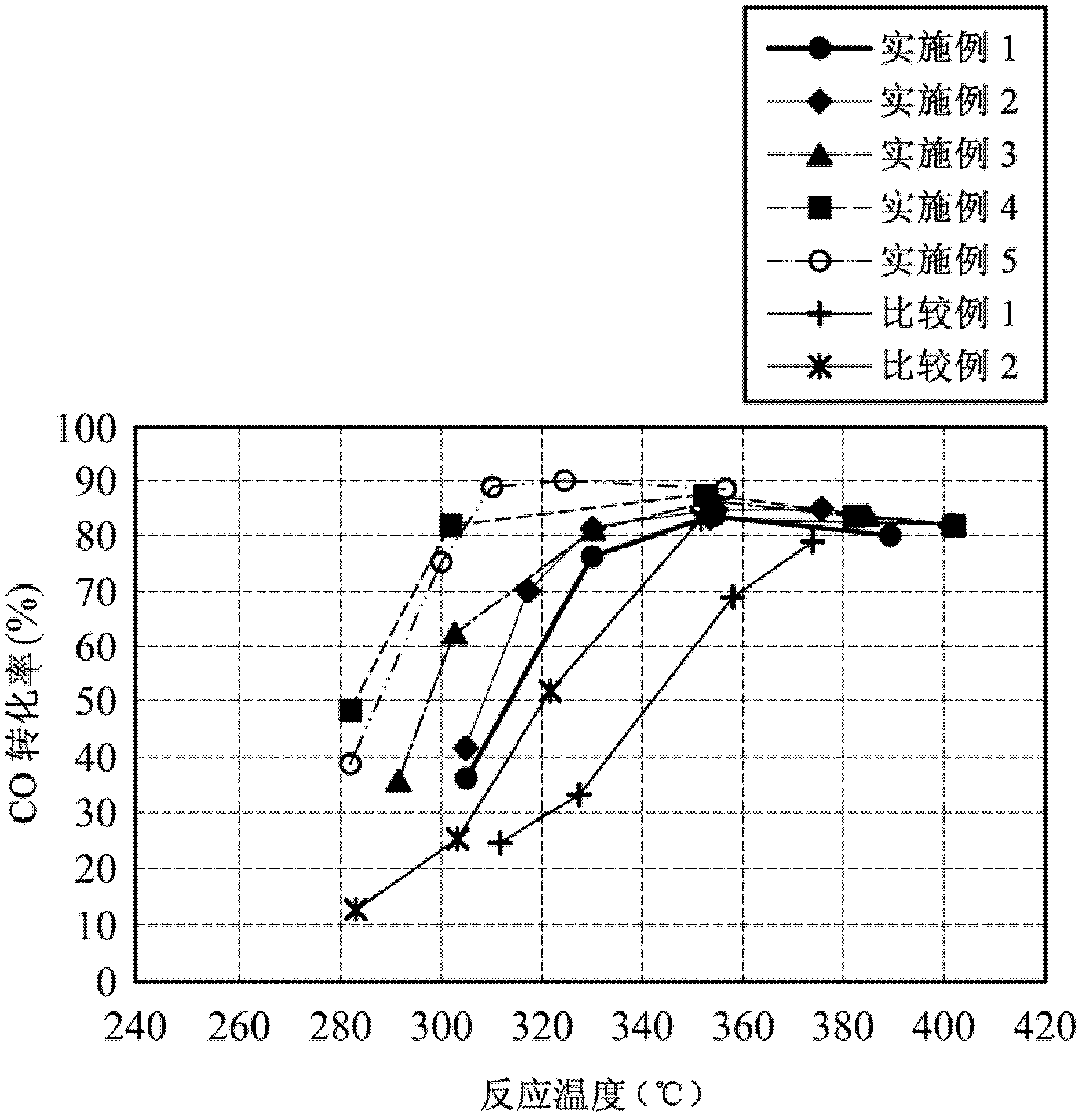

Embodiment 1

[0026] 20g of zirconia cerium was added to the platinum solution (Pt(NO 2 ) 2 (NH 3 ) 2 solution, containing 0.3g platinum), heated to 120°C and maintained for 5 hours to remove the solvent, and then heated to 500°C for 2 hours to obtain a platinum-coated zirconia-cerium catalyst, wherein the weight of zirconia-cerium and platinum The ratio is 100:1.5.

[0027] Take 6.25g of zirconia-cerium catalyst covered with platinum on the surface, mix it with 4.25g of zirconia powder, then add 2g of aluminum colloidal powder, adjust the solid content of the above mixture to about 49% with 13g of water, grind to form a slurry, adjust The viscosity of the slurry is between 10 and 100cP (the viscosity of the slurry is measured by a rotary viscometer), and the slurry is coated on a 400 hole / square inch (cells / in) with a diameter of 2 cm and a length of 4 cm. 2 ) ceramic honeycomb carrier (a cylinder with a diameter of 2 cm, a length of 4 cm, and a total volume of the catalyst of 12.6 cub...

Embodiment 2

[0029]Similar to Example 1, the only difference is that the platinum solution contains 0.4g of platinum, so that the weight ratio of zirconia-cerium oxide to platinum in the platinum-coated zirconium-cerium oxide catalyst is 100:2. In the catalyst finally coated on the pore surface of the honeycomb carrier, platinum accounted for about 1.0% by weight in the catalyst coating layer on the surface of the honeycomb carrier.

Embodiment 3

[0031] Similar to Example 1, the only difference is that the platinum solution contains 0.5 g of platinum, so that the weight ratio of zirconia-cerium oxide to platinum in the platinum-coated zirconium-cerium oxide catalyst is 100:2.5. In the catalyst finally coated on the pore surface of the honeycomb carrier, platinum accounted for about 1.25% by weight in the catalyst coating layer on the surface of the honeycomb carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com