Chain conveying device

A technology of transmission device and chain, applied in the field of chain transmission device, can solve the problems of increasing site space, increasing manufacturing cost, increasing cost of occupied space, etc., and achieving the effect of reducing overall size and utilizing site utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0010] The present invention will be described below with reference to the drawings.

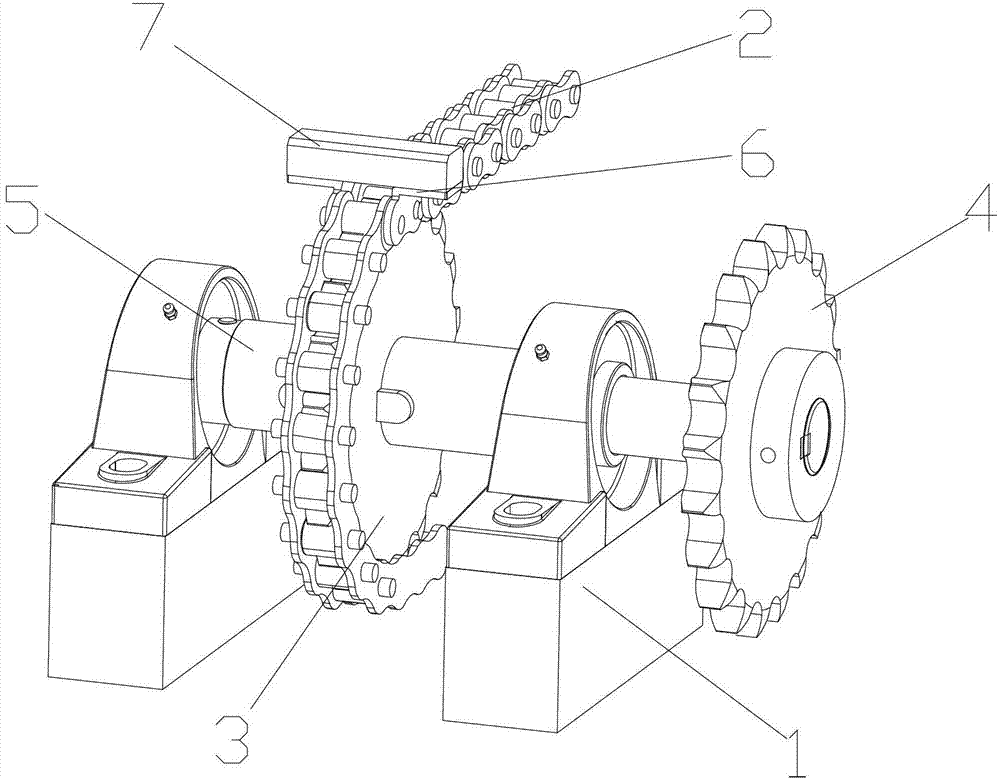

[0011] Attached figure 1 It is a chain transmission device according to the present invention, comprising a shaft frame 1, a chain 2; the shaft frame 1 is connected to a first gear 3 through a connecting shaft 5; the end of the connecting shaft 5 is provided with a second gear 4; The chain 2 is meshed with the first gear 3; the chain 2 of the chain is provided with a single-hole bent plate 6; the single-hole bent plate 6 is equipped with a baffle 7; the second gear 4 is connected to the motor to drive The connecting shaft 5 rotates, the movement of the first gear 3 drives the chain 2 to move, and the single-hole bent plate 6 on the chain 2 moves with the chain 2 to push the workpiece to move; the solution of the present invention is provided by the single-hole bent plate 6 and the baffle 7 on the chain 2 The movement of the workpiece is realized during the transmission process. When the first ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap