Method for manufacturing refractory clay for constructing refractory bricks of flame path walls of baking furnaces

A technology of refractory brick masonry and refractory mud, which is applied in the field of preparation of refractory mud for the refractory brick masonry of the flue wall of the roasting furnace, which can solve the problems of low refractoriness, deformation and damage of the flue wall, and low bonding strength. Achieve the effects of high refractoriness, long service life and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

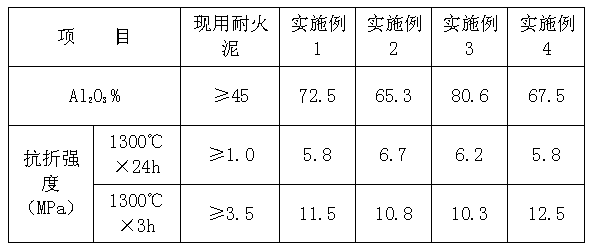

Examples

Embodiment 1

[0026] Embodiment 1: choose the raw material component of following parts by weight:

[0027] High alumina bauxite clinker Ⅰ (Al 2 o 3 content ≥ 75%) particle size ≤ 0.088mm 45 parts,

[0028] Mullite clinker (Al 2 o 3 content ≥ 70%) particle size ≤ 0.088mm 20 parts,

[0029] Alumina powder (Al 2 o 3 Content ≥ 98%) Particle size ≤ 0.043mm 5 parts,

[0030] High alumina bauxite clinker Ⅱ (Al 2 o 3 content ≥75%) particle size ≤0.043mm 10 parts,

[0031] High alumina bauxite clinker Ⅲ (Al 2 o 3 Content ≥ 55%) Particle size ≤ 0.043mm 10 parts,

[0032] High-quality kaolin (Al 2 o 3 Content ≥ 30%) Particle size ≤ 0.043mm 8 parts,

[0033] Sodium carboxymethyl cellulose 2 parts,

[0034] Sodium tripolyphosphate 2 parts,

[0035] 2 parts yellow dextrin,

[0036] After preparing according to the number of parts by weight, add it to the mixer for mixing and stirring. The stirring time is ≧10 minutes. The fully stirred mixture is sealed and bagged for later use.

[00...

Embodiment 2

[0038] Embodiment 2: choose the raw material component of following parts by weight:

[0039] High alumina bauxite clinker Ⅰ (Al 2 o 3 content ≥75%) particle size ≤0.088mm 48 parts,

[0040] Mullite clinker (Al 2 o 3 content ≥ 70%) particle size ≤ 0.088mm 15 parts,

[0041] Alumina powder (Al 2 o 3 Content ≥ 98%) Particle size ≤ 0.043mm 6 parts,

[0042] High alumina bauxite clinker Ⅱ (Al 2 o 3 content ≥75%) particle size ≤0.043mm 10 parts,

[0043] High alumina bauxite clinker Ⅲ (Al 2 o 3 Content ≥ 55%) Particle size ≤ 0.043mm 12 parts,

[0044] High-quality kaolin (Al 2 o 3 content ≥30%) particle size ≤0.043mm 10 parts,

[0045] Sodium carboxymethyl cellulose 1 part,

[0046] Sodium tripolyphosphate 2 parts,

[0047] Sodium hexametaphosphate 1 part,

[0048] Yellow dextrin 2.5 parts,

[0049] After preparing according to the number of parts by weight, add it to the mixer for mixing and stirring. The stirring time is ≧10 minutes. The fully stirred mixture i...

Embodiment 3

[0051] Embodiment 3: choose the raw material component of following parts by weight:

[0052] High alumina bauxite clinker Ⅰ (Al 2 o 3 Content ≥ 75%) Particle size ≤ 0.088mm 53 parts,

[0053] Mullite clinker (Al 2 o 3 content ≥ 70%) particle size ≤ 0.088mm 18 parts,

[0054] Alumina powder (Al 2 o 3 Content ≥ 98%) Particle size ≤ 0.043mm 8 parts,

[0055] High-quality kaolin (Al 2 o 3content ≥ 30%) particle size ≤ 0.043mm 15 parts,

[0056] Sodium carboxymethyl cellulose 1.5 parts,

[0057] Sodium tripolyphosphate 1.5 parts,

[0058] Yellow dextrin 1.5 parts,

[0059] After preparing according to the number of parts by weight, add it to the mixer for mixing and stirring. The stirring time is ≧10 minutes. The fully stirred mixture is sealed and bagged for later use.

[0060] When building refractory bricks, add the bagged mixture to the mud mixer on site, and then weigh 33 parts of clean tap water according to the total weight of the mixture as 100, and add it to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com