Preparation method for modified inorganic fiber cloth

A technology of inorganic fiber modification, applied in the field of preparation of modified inorganic fiber cloth, can solve the problems of limited temperature resistance and easy aging of silane coupling agent, achieve high temperature resistance, strengthen mechanical bonding, and simple configuration easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

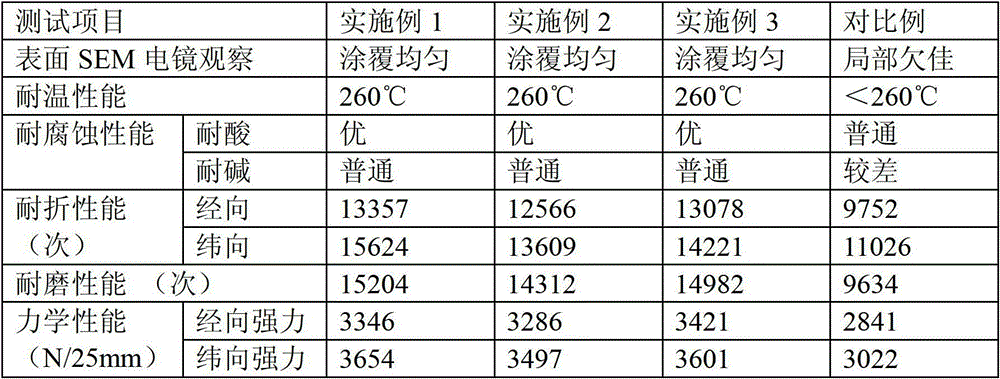

Examples

Embodiment 1

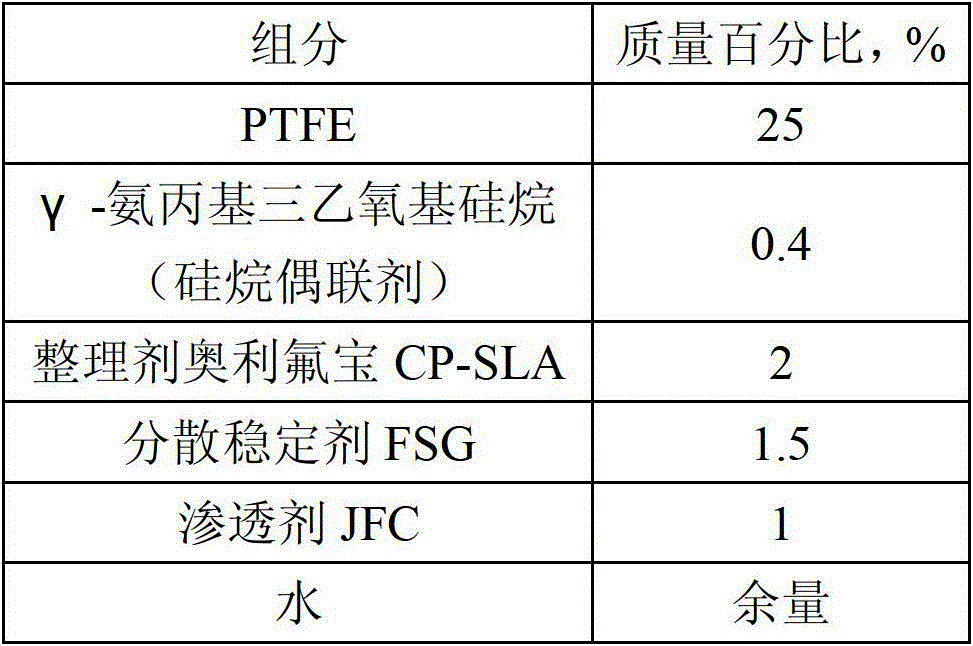

[0026] Prepare surface treatment agent:

[0027] components

Mass percentage, %

PTFE

25

0.3

Finishing agent Ori Fluoro 7713

2

Dispersion Stabilizer FSN-100

1

Penetrant JFC

1

water

margin

[0028] Mix the above components evenly to obtain the surface treatment agent.

[0029] Use ultrasonic cleaning in 3wt% amylase solution at 90°C for 5 minutes to remove the wetting agent on the glass fiber cloth, then soak the glass fiber cloth in the surface treatment agent for 1 minute, and finally dry it at 180°C for 2 minutes. Bake at 260°C for 10 minutes to obtain.

Embodiment 2

[0031] Prepare surface treatment agent:

[0032] components

Mass percentage, %

PTFE

5

4

Finishing agent Ori Fluoro OC

1

Dispersion stabilizer FSO-100

0.5

Penetrant JFC-1

0.5

water

margin

[0033] Mix the above components evenly to obtain the surface treatment agent.

[0034] Remove the sizing agent on the glass fiber cloth by sintering at 250°C for 24h, then soak the glass fiber cloth in the surface treatment agent for 0.5min, dry at 200°C for 4min, and bake at 280°C for 8min , that is.

Embodiment 3

[0036] Prepare surface treatment agent:

[0037] components

Mass percentage, %

PTFE

40

0.05

0.05

Olivier SLA-NEW

4

Dispersion stabilizer FSO-100

0.01

Penetrant JFC-2

4

water

margin

[0038] Mix the above components evenly to obtain the surface treatment agent.

[0039] Use the hot cleaning method at 400°C for 45s to remove the sizing agent on the basalt fiber cloth, then soak the basalt fiber cloth in the surface treatment agent for 3 minutes, dry at 220°C for 5 minutes, and bake at 260°C for 15 minutes. Instantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com