Spinneret plate microscopy instrument

A spinneret and microscope technology, which is applied in the field of detection systems, can solve problems such as inconvenient detection and affect detection accuracy, and achieve the effects of increasing reliability, ensuring accuracy, and avoiding inaccurate detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

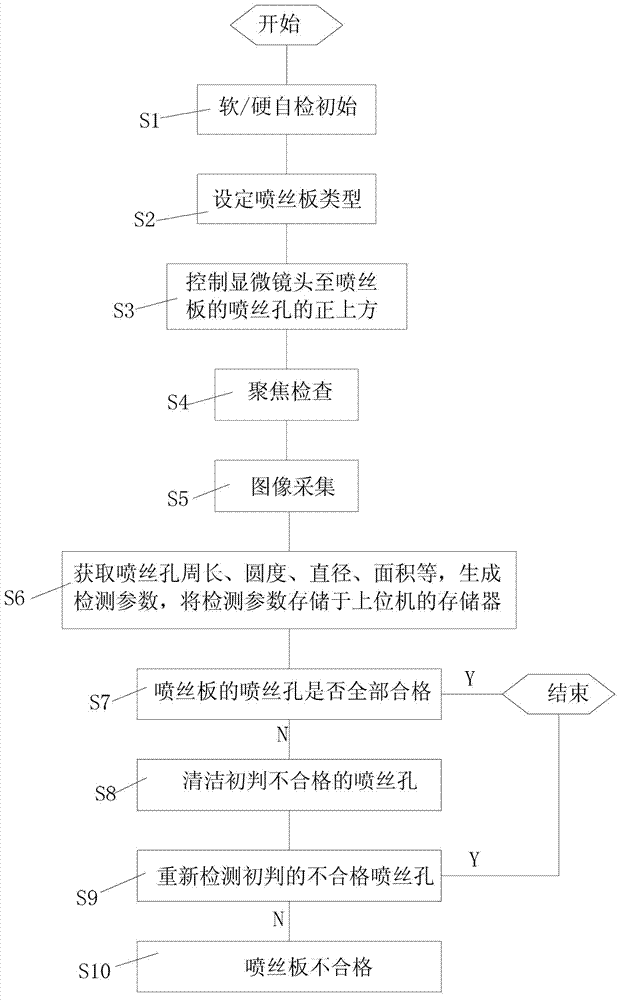

[0025] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

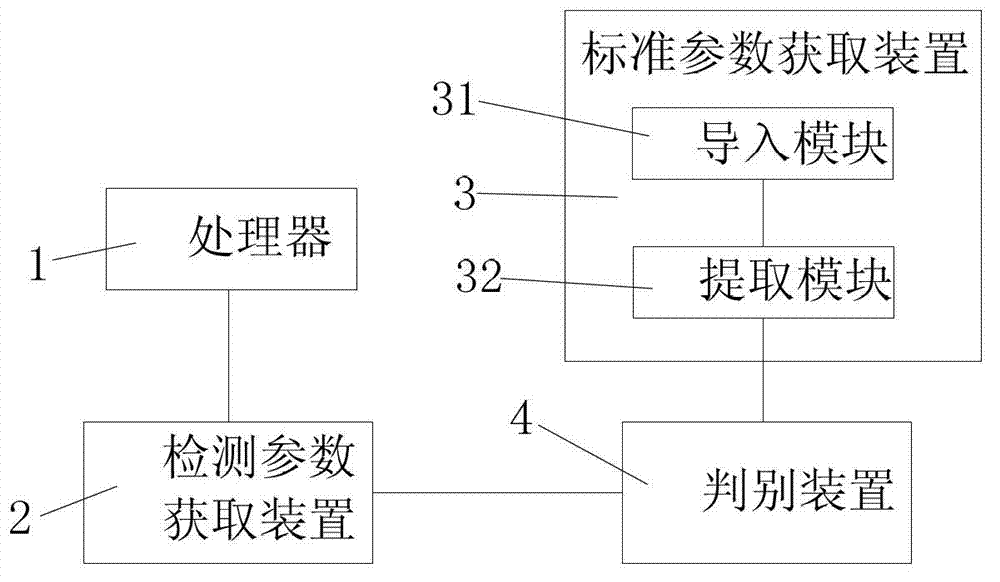

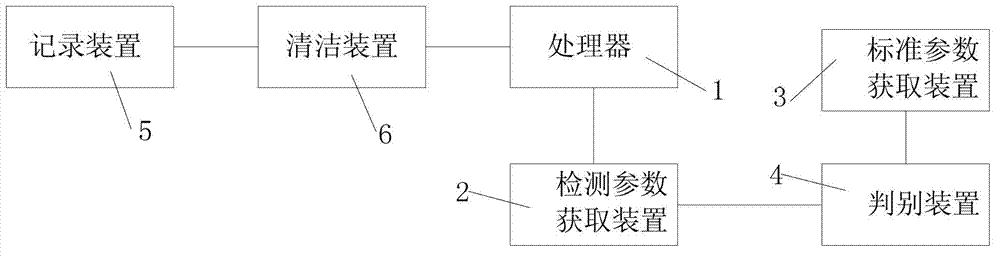

[0026] see figure 1, The spinneret mirror inspection instrument of the present invention includes a processor 1 , a detection parameter acquisition device 2 , a standard parameter acquisition device 3 and a discrimination device 4 . The detection parameter acquisition device 2 obtains the image of the spinneret hole of the spinneret to be tested and the relative position of the spinneret hole and the reference point. For example, the detection parameter acquisition device 2 can include a three-axis Mobile workbench and industrial camera. Place the spinneret to be tested on the workbench, and each spinneret hole on the spinneret to be tested can be photographed by the industrial camera, in order to make the image captured by the industrial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com