Composite magnetic core and its manufacturing method

A composite and magnetic core technology, which is applied in the manufacture of inductors/transformers/magnets, the magnetism of inorganic materials, and electrical components, can solve problems such as difficult molds, sedimentation, and large specificity of magnetic powders, and avoid air bubbles and uneven magnetic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

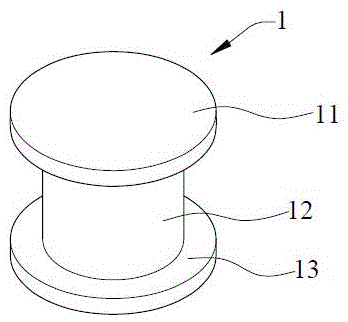

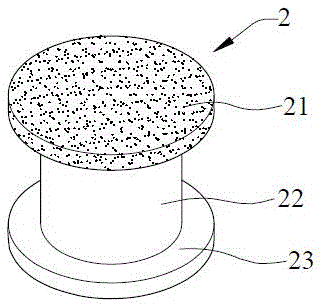

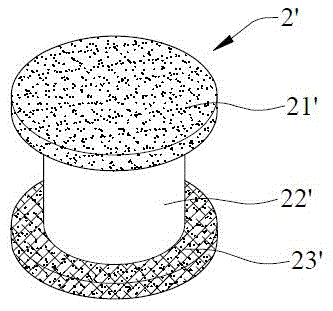

[0023] see Figure 2A . The magnetic core 2 includes an upper end portion 21, a columnar portion 22 and a lower end portion 23, wherein the upper end portion 21 and the lower end portion 23 are formed at both ends of the columnar portion 22, and the upper end portion 21 and the lower end portion 23 are perpendicular to the extending direction of the columnar portion 22. The cross-sectional area can be larger than the cross-sectional area of the columnar portion 22 perpendicular to its extending direction, forming a magnetic core similar to the Chinese "工" or English "I".

[0024] At least one of the upper end portion 21 and the lower end portion 23 can be made of a mixture of powdered magnetic material and powdered adhesive in a predetermined ratio, and formed at both ends of the columnar portion 22 . Such as Figure 2A As shown, the upper end 21 of the magnetic core 2 is made of a mixture, and is bonded to one end of the columnar portion 22 by heating. Alternatively, the...

no. 2 example

[0036] see Figure 4The magnetic core 5 includes a core material 51 and a covering body 52 covering the core material 51 , the core material 51 is annular and has a hollow portion 510 , and the core material 51 has a notch 511 . The covering body 52 is made of a mixture of powdery magnetic material and powdery adhesive. The covering body 52 covers the core material 51 and forms a through hole 520 in the hollow portion 510 of the core material 51 . That is to say, the covering body 52 coaxially covers the entire core material 51 and forms a through hole 520 along the axis of the core material 51 .

[0037] Opening a notch 511 on the (ring) core material 51 can change the hysteresis curve of the core material 51, and using the (ring) core material 51 with the notch 511 to make an inductor can obtain better inductance characteristics, but the magnetic field lines will be at the notch 511 Exposure causes eddy current loss, increased reluctance and decreased magnetic permeability....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com