Production process for silicification of dry powder

A production process and dry powder technology, applied in fire protection equipment and other directions, can solve the problems of uneconomical, large hygroscopicity, and large environmental pollution, and achieve the effect of good effect, uniform oil encapsulation, and small environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

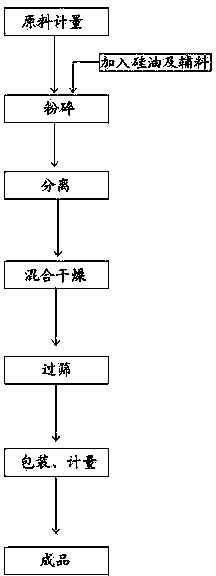

[0032] Such as figure 1 Shown, a kind of dry powder silicification production process, described process comprises the steps:

[0033] The first step is to weigh the dry powder raw material ammonium sulfate and ammonium phosphate.

[0034] In the second step, the above-mentioned weighed raw materials are put into a pulverizer for crushing, and the speed of the pulverizer is adjusted to 2800 rpm, and the original intermittent point operation is changed into a continuous line operation; while pulverizing, add Silicone oil, auxiliary materials such as white carbon black and mica powder, etc., the silicone oil here is prepared with organic solvents such as benzene and banana water in a ratio of 1:3, and then added to the pulverizer to siliconize the raw materials and oil them. Pack oil, control the crushing speed at about 1 ton / hour, so as to adjust the amount of silicone oil.

[0035] By adding silicone oil when crushing the raw materials and carrying out siliconization at the ...

Embodiment 2

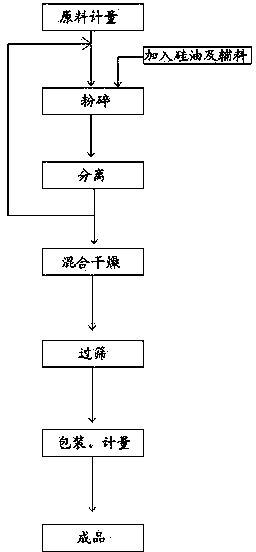

[0042] Such as figure 2 As shown, all the other are the same as in Example 1, the difference is that in the third step of the above-mentioned technological process, in this operation process, the material with the qualified particle size separated is put into the next step operation, otherwise the material is re- Put it into the pulverizer in the second step for crushing. Through this step, the raw materials can be fully utilized, saving costs and improving economic benefits.

Embodiment 3

[0044] The rest is the same as the above-mentioned embodiment, the difference is that the speed of the pulverizer is adjusted to 3200 rpm, and the temperature of the mixer is controlled at 200°C, which can achieve the above-mentioned advantages of less oil consumption, uniform oil mixing, and less environmental pollution. Purpose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com