Method for preparing cadmium selenide nano-belt

A nanobelt and cadmium selenide technology, applied in the chemical characteristics of fibers, chemical post-treatment of rayon, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

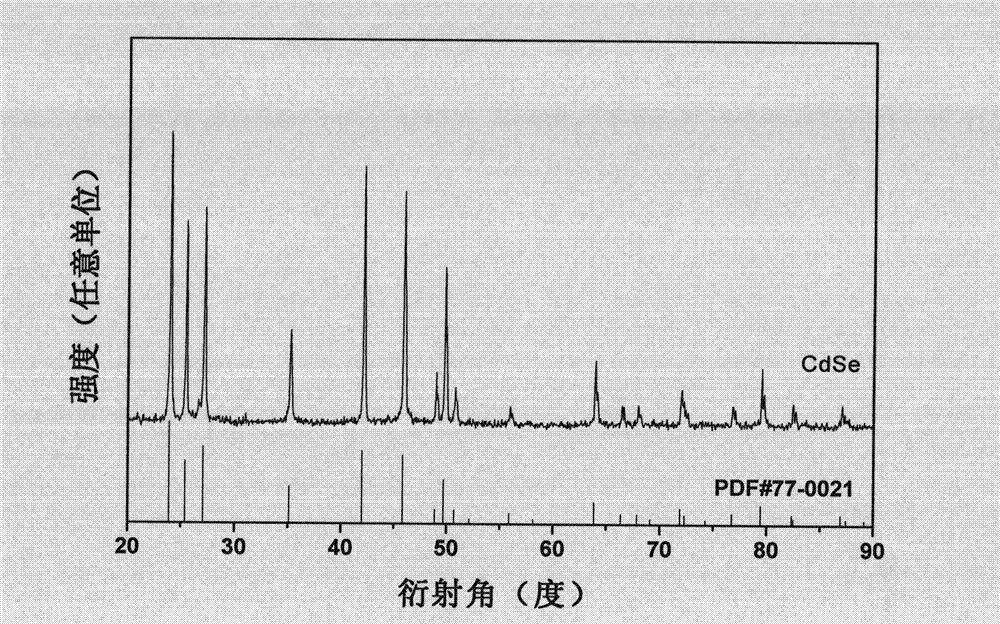

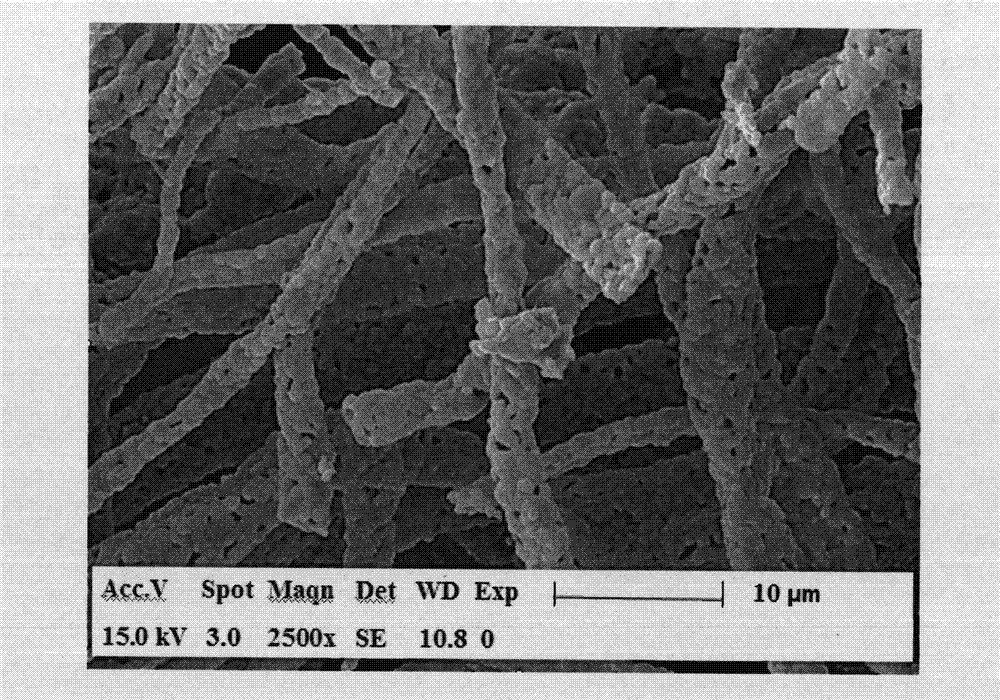

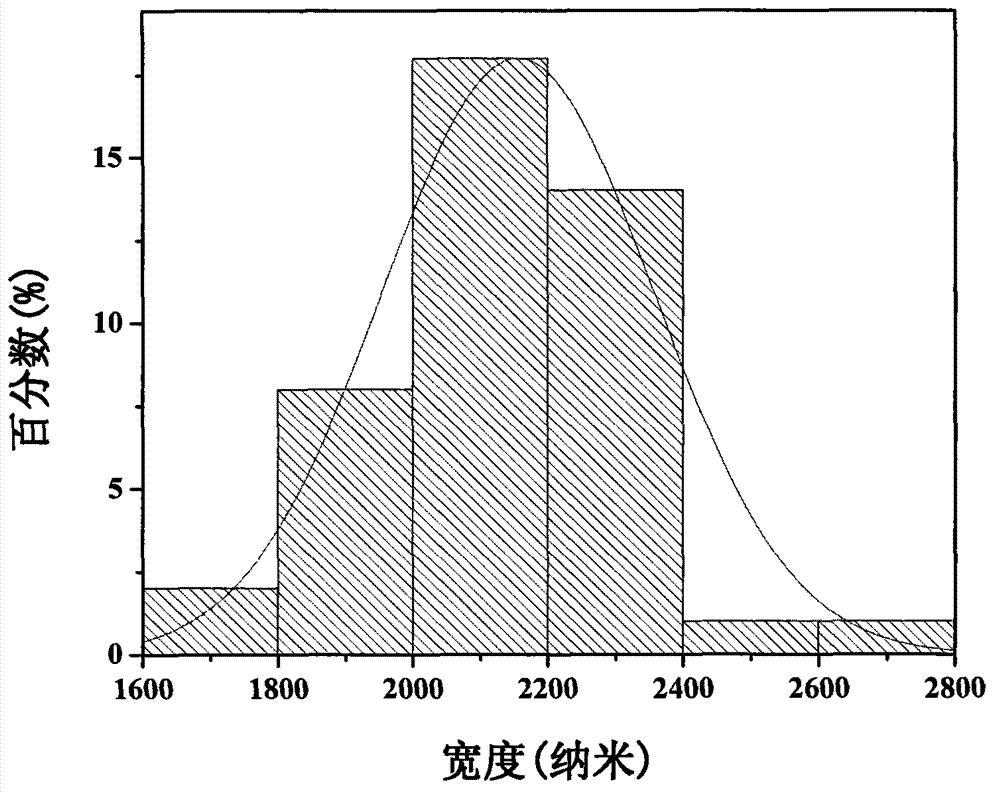

[0022] Embodiment: take a certain amount of cadmium carbonate CdCO 3 , with HNO 3 Dissolved and heated to evaporate to obtain Cd(NO 3 ) 2 , adding solvent N,N-dimethylformamide DMF and polyvinylpyrrolidone PVP, magnetic stirring at room temperature for 6h, and standing for 3h to form a spinning solution, the mass percentage of each component of the spinning solution is: cadmium nitrate content of 10%, PVP content of 20%, and solvent DMF content of 70%; the prepared spinning solution is added to the liquid storage pipe of the spinning device for electrospinning. DC voltage, curing distance 14cm, room temperature 18-25°C, relative humidity 50%-60%, PVP / Cd(NO 3 ) 2 Composite nanobelt, the PVP / Cd(NO 3 ) 2 The composite nanobelts were heat-treated in a temperature-programmed furnace with a heating rate of 1°C / min, kept at 500°C for 4 hours, then cooled down to 200°C at a rate of 1°C / min, and then naturally cooled to room temperature with the furnace body to obtain CdO nanobe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com