Pneumatic split side measurer

A measuring instrument and pneumatic technology, applied in the field of measurement, can solve the problems such as the central axis not necessarily collinear, the measurement results are biased, and the same force cannot be guaranteed, so as to avoid errors, the measurement results are accurate, and it is conducive to repeated measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

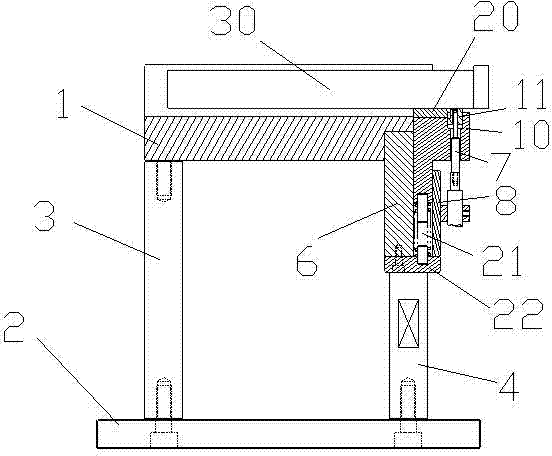

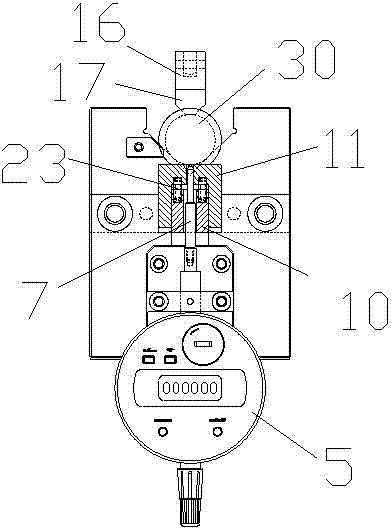

[0027] Such as Figure 1-Figure 8 As shown, a pneumatic profile measuring device includes a reference base 1 and a base plate 2, a rear support column 3 and a front support column 4 are connected between the reference base 1 and the base plate 2, and the middle position of the reference base 1 is set There is a V-shaped groove 101, the symmetry of the V-shaped groove 101 is 0.01, and the straightness is 0.01, which ensures that the axis of the product placed in the V-shaped groove 101 is on the same vertical plane as the center line of the V-shaped groove. A slider guide 6 is also connected between the reference seat 1 and the front support column 4, a slider 10 is arranged in the chute 601 of the slider guide 6, and a spring support plate is provided at the bottom of the slider guide 6 22. The chute 601 between the spring support plate 22 and the slider 10 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com