Semiconductor laser calibrating and testing method and application thereof

A test method and laser technology, applied in the field of optical communication, can solve the problems of laser tracking error, inaccurate calibration accuracy, not taking into account temperature gradient and environmental temperature changes, etc., so as to solve the tracking error and improve the calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

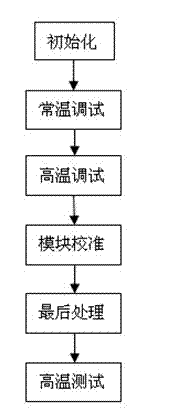

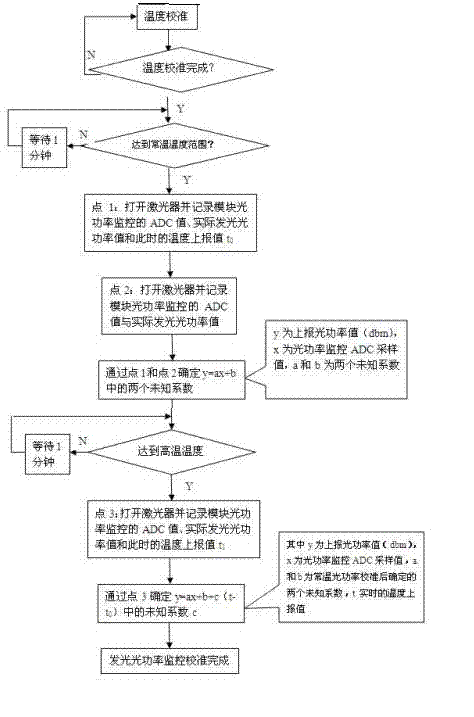

[0034] The calibration error of the semiconductor laser mainly comes from the temperature gradient of the internal die of the laser device and the temperature reference point, which directly affects the calibration of the optical power at the transmitting end, the optical wavelength of the wavelength division multiplexing (WDM) channel, and the optical power at the receiving end. Considering the commonality of these calibration methods, this article only discusses the calibration and monitoring of the luminous optical power.

[0035] The following takes the EML laser with temperature control widely used in optical fiber communication as an example, and specifically introduces the testing method of the present invention. Of course, the method is also applicable to other semiconductor lasers.

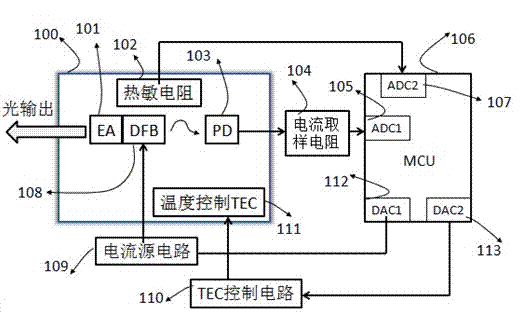

[0036] Such as figure 1 As shown, consistent with the prior art, a semiconductor EML laser 100 with temperature control consists of an electroabsorption (EA) 101, a distributed reflective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com