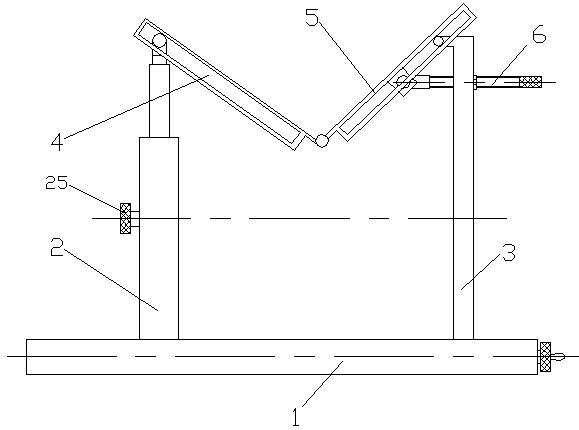

Slag detachability evaluation test method and device of submerged arc welding agent

A submerged arc flux and evaluation test technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of hidden safety hazards of welding joints, non-quantitative description, easy to be caught in the weld, etc., to improve design and development, The effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

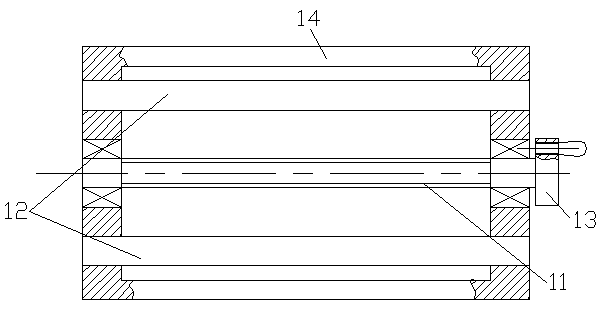

[0024] A submerged arc welding flux slag detachability evaluation test method, comprising the following steps:

[0025] Step 1, setting the standard for effective slag removal; in this embodiment, the standard for effective slag removal is set to be effective slag removal when the automatic slag shedding length is greater than or equal to 50% of the effective weld length;

[0026] Step 2, determine a standard submerged arc welding process, and use this process as the evaluation test standard; the standard submerged arc welding process selected in this embodiment is that the welding materials are based on the international standard GB / T3429-2002 for welding steel wire rods Choose H08A welding wire, the specification is Ф3.2mm, the welding process parameters are: welding current 425~525A, welding voltage 27~30V, welding speed 23m / h. H08A welding wire: chemical composition (%)

[0027] C≤0.1; Mn0.35~0.6; Si≤0.03; Cr≤0.2; Ni≤0.3; Cu≤0.2; S, P not greater than 0.03.

[0028] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com