Production process of maotai-flavor fruit wine

A production process and fruit wine technology, which is applied in the field of production technology of Maotai-flavored fruit wine, and can solve the problems of different strong aromas and fragrances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

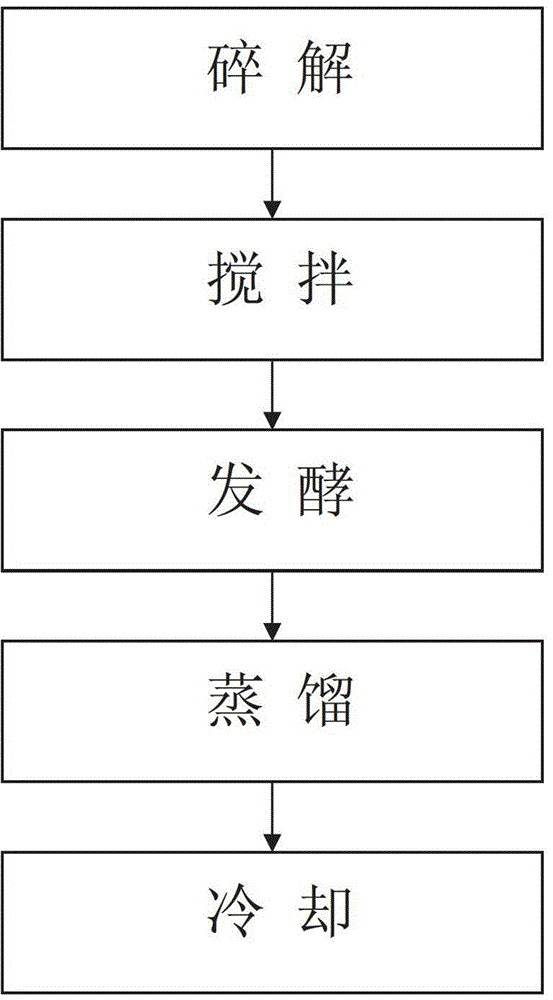

[0026] A kind of production technology of sauce-flavored fruit wine of the present invention is characterized in that, comprises the following steps:

[0027] 1) Disintegration: send the cleaned fresh fruit to the disintegration machine through the conveyor belt, after disintegration, filter out the fruit pomace seeds to obtain fruit mash;

[0028] 2) Stirring: Put the crushed fruit mash into the storage tank, add the sauce-flavored base wine Moutai liquor for stirring;

[0029] 3) Fermentation: Connect the fruit mash obtained after stirring to a fermenter at a fermentation temperature of 30°C, use immobilized yeast as a carrier, add dry yeast with a fruit mash content of 5%, mix well, and ferment for 40 hours;

[0030] 4) Distillation: send the fermented mash into a distillation tower with a set temperature of 80°C, add 10% sodium hydroxide by mass at the same time, distill for 20 minutes, and purify the alcohol in the mash, and the alcohol that does not reach the concentrati...

Embodiment 2

[0033] 1) Disintegration: send the cleaned fresh fruit to the disintegration machine through the conveyor belt, after disintegration, filter out the fruit pomace seeds to obtain fruit mash;

[0034] 2) Stirring: Put the crushed fruit mash into the storage tank, add the sauce-flavored base wine Moutai liquor for stirring;

[0035] 3) Fermentation: Connect the fruit mash obtained after stirring to a fermenter at a fermentation temperature of 32°C, use immobilized yeast as a carrier, add dry yeast with a fruit mash content of 8%, mix well, and ferment for 50 hours;

[0036] 4) Distillation: Send the fermented mash into a distillation tower with a set temperature of 85°C, add 12% sodium hydroxide at the same time, distill for 25 minutes, and purify the alcohol in the mash, and the alcohol that does not reach the concentration index Circular distillation, the distiller's grains are discharged from the distiller's grain tank;

[0037] 5) Cooling: the alcohol produced in the distill...

Embodiment 3

[0039] 1) Disintegration: send the cleaned fresh fruit to the disintegration machine through the conveyor belt, after disintegration, filter out the fruit pomace seeds to obtain fruit mash;

[0040] 2) Stirring: Put the crushed fruit mash into the storage tank, add the sauce-flavored base wine Moutai liquor for stirring;

[0041] 3) Fermentation: Connect the fruit mash obtained after stirring to a fermenter at a fermentation temperature of 30° C., use immobilized yeast as a carrier, add dry yeast with a fruit mash content of 6%, mix well, and ferment for 60 hours;

[0042] 4) Distillation: Send the fermented mash into a distillation tower with a set temperature of 85°C, add 18% sodium hydroxide at the same time, distill for 30 minutes, and purify the alcohol in the mash, and the alcohol that does not reach the concentration index Circular distillation, the distiller's grains are discharged from the distiller's grain tank;

[0043] 5) Cooling: the alcohol produced in the disti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com