Flexible reversed-U-shaped integral steel oil ring

A U-shaped, steel-based technology, applied in the field of oil rings, can solve the problems of short service life, high production cost, and fast wear, and achieve the effects of saving raw materials, long-lasting self-tension, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

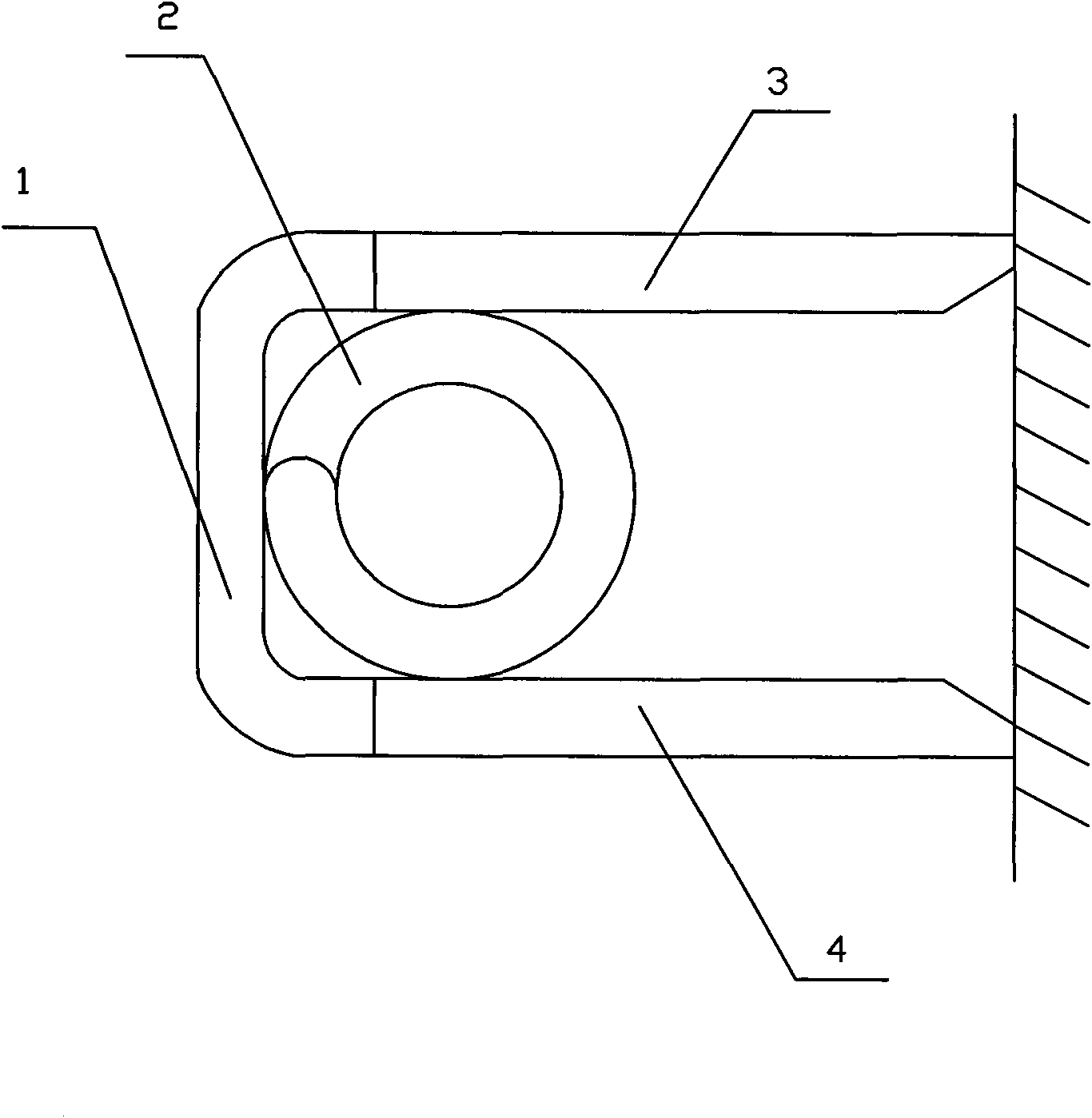

[0009] A flexible inverted U-shaped integrated steel oil ring, including an annular base 1 and a helical expansion spring 2, the annular base 1 has a U-shaped cross section, and is composed of an upper scraper 3, a lower scraper 4 and a ring groove , the upper oil scraper 3 and the lower oil scraper 4 are parallel to each other, the inner ring of the inverted U-shaped annular base 1 is provided with spiral cuts, and the two ends are crossed and evenly cut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com