Sealing property testing device for PCCP (prestressed concrete cylinder pipe) pipeline connector

A technology for pipe joints and test devices, which is applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve problems such as the influence of installation accuracy and test result error, so as to reduce labor and time consumption, simplify test equipment, and improve The effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

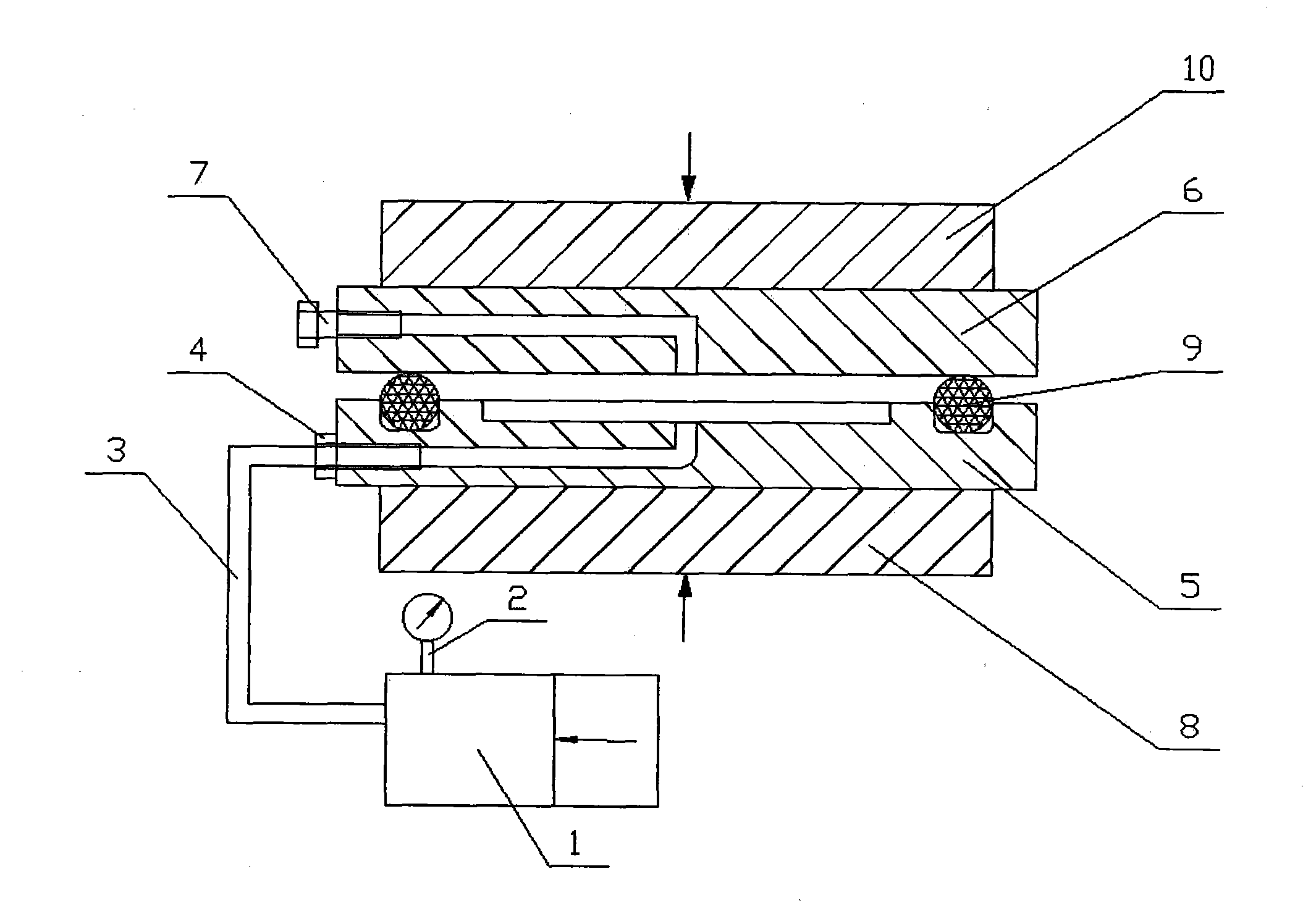

[0008] During the test, first put the socket plate (5) on the base (8) of the pressure testing machine; paint the water-stop rubber ring (9) prepared in advance and put it into the socket groove of the socket plate (5). , cover the socket plate (6) to ensure that it is stable and does not slide relatively; adjust the workbench (10) of the pressure testing machine so that the workbench (10) of the pressure testing machine is in contact with the socket plate (6); 1) Pour water into the water storage tank of the socket plate (5), wait for the water to flow out from the water channel in the socket plate (6), and use the plugging bolt (7) to stop the water.

[0009] Use a vernier caliper to measure the gap between the socket plate (5) and the socket plate (6), use the pressure pump (1) to pressurize until there is a water leakage point, record the value of the pressure gauge (2), and open the plugging bolt ( 7) Release the pressure, raise the working table (10) of the pressure test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com