Through jig and non-twisted cable assembling device

A wire passing and jig technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as flip-deformation, unstable scratch level, high-frequency data transmission cables that cannot meet the transmission performance, etc., to achieve Reduces the effect of cable twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

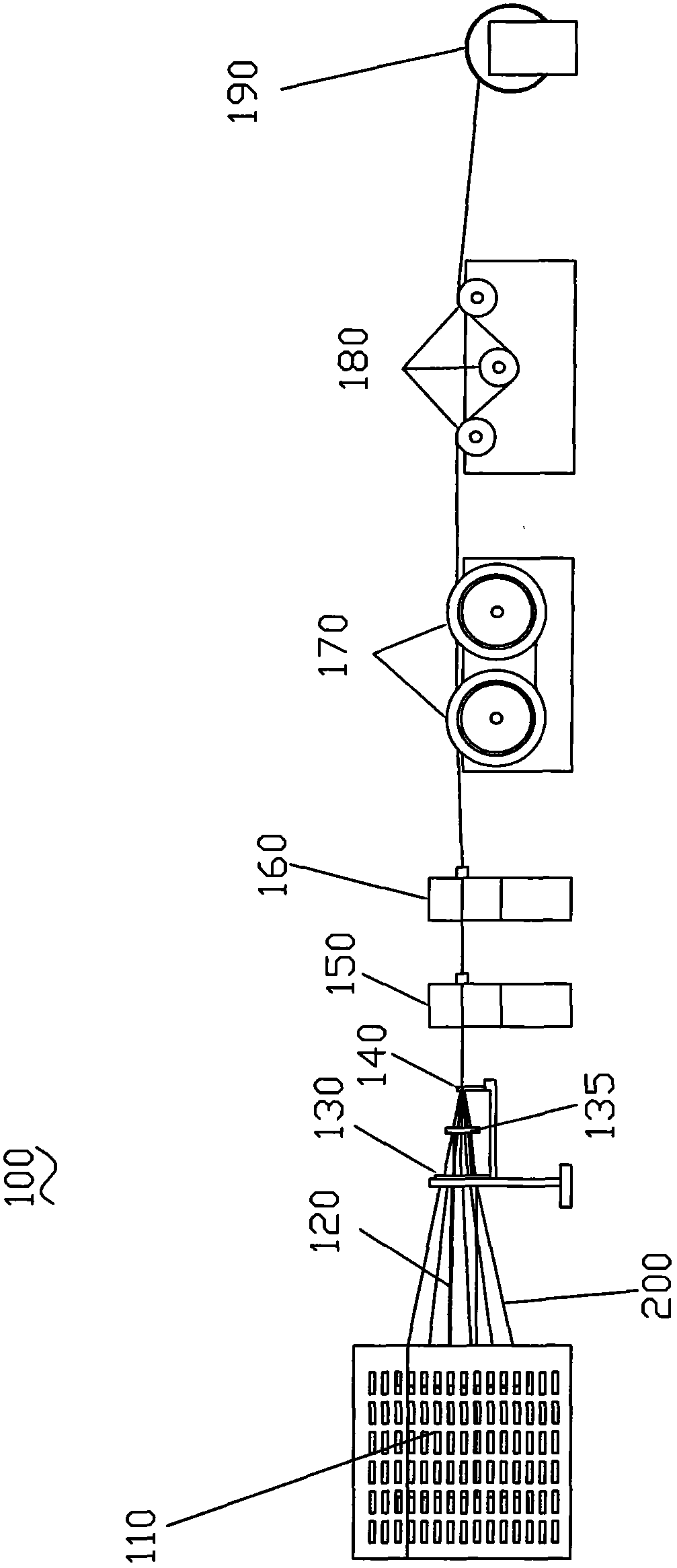

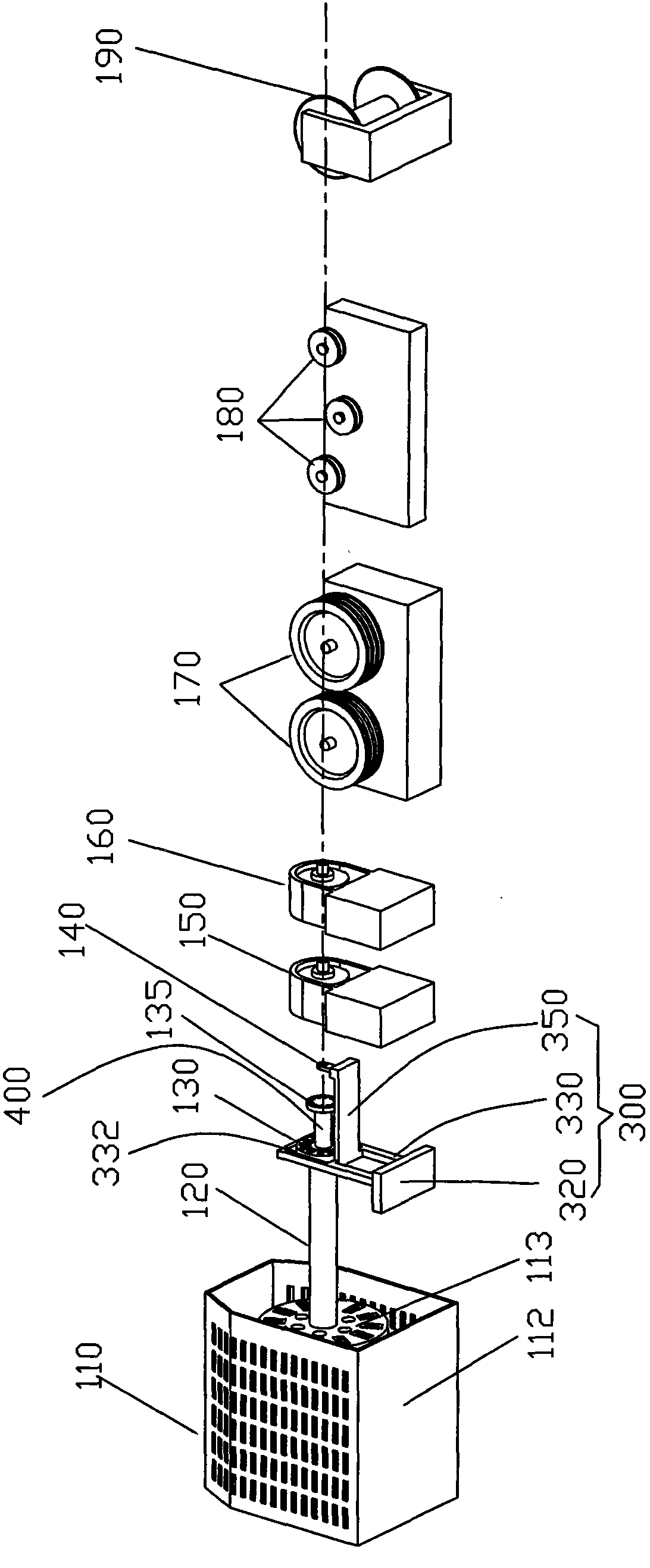

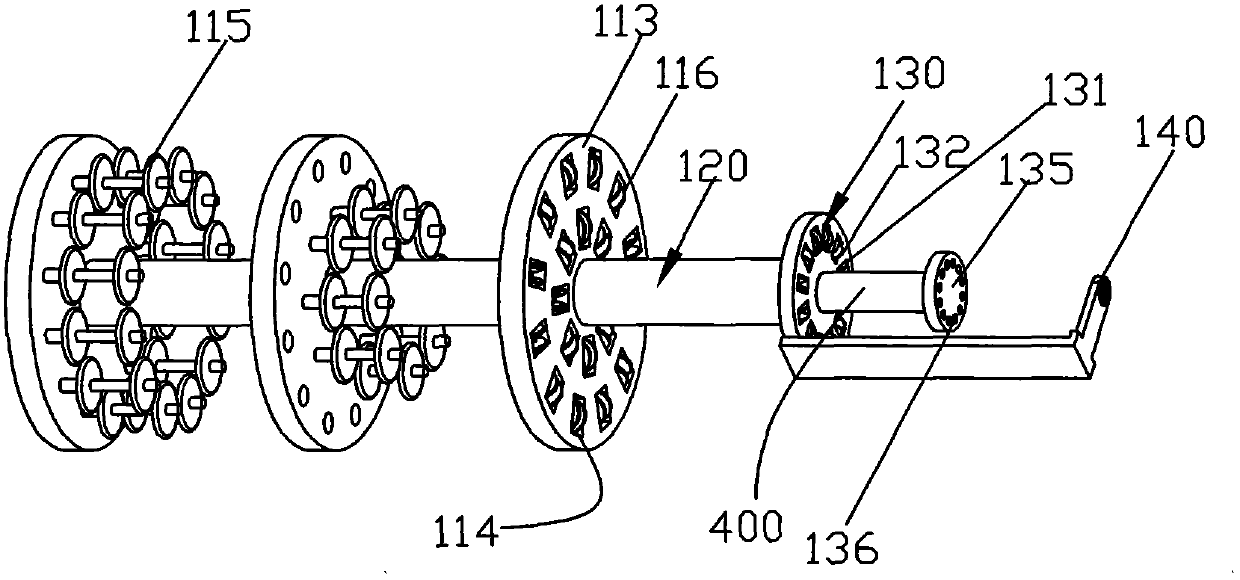

[0021] figure 1 and figure 2 Shown is a schematic diagram of the untwisted cable assembly device 100 according to an embodiment of the present invention. Such as figure 1 and figure 2 As shown in , the untwisted cable assembly device 100 includes a main transmission device 110, a transmission shaft 120, a cable distributor 130, a wire passing ceramic eye device 135, a cable eye mold 140, a first assembly tape device 150, The second collective tape wrapping device 160 , the rotating drawing device 170 , the tension buffering wire guide wheel 180 and the wire t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com