Differential roll bending method of working roll and used for controlling nonsymmetrical flatness defects

A technology of work roll bending and work roll, which is applied in the field of cold-rolled strip rolling, can solve the problems of low steady-state accuracy and large instantaneous fluctuation, and achieve stable flatness standard deviation distribution, small average flatness standard deviation, Eliminates the effect of low steady-state accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

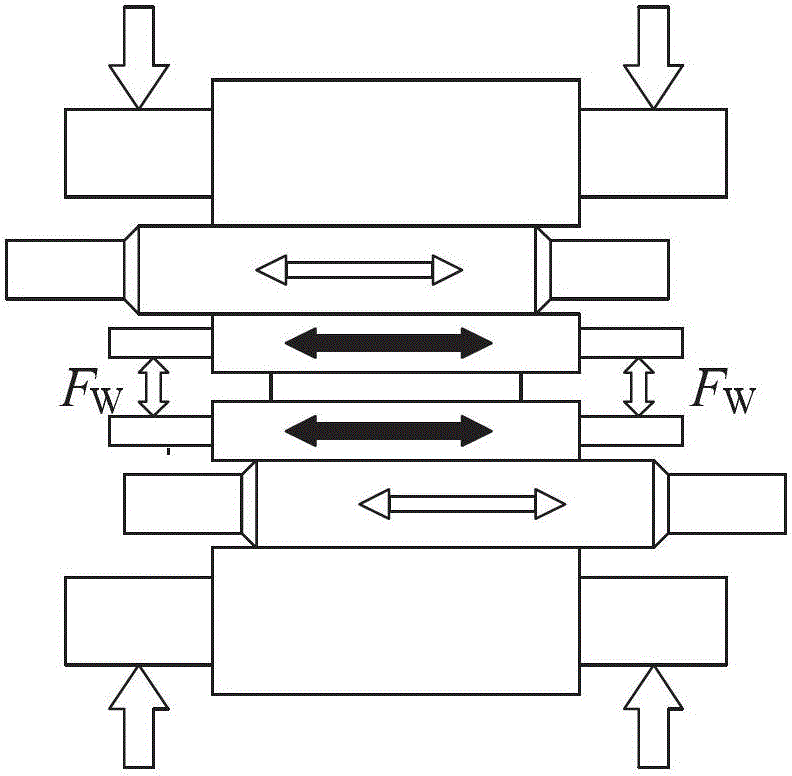

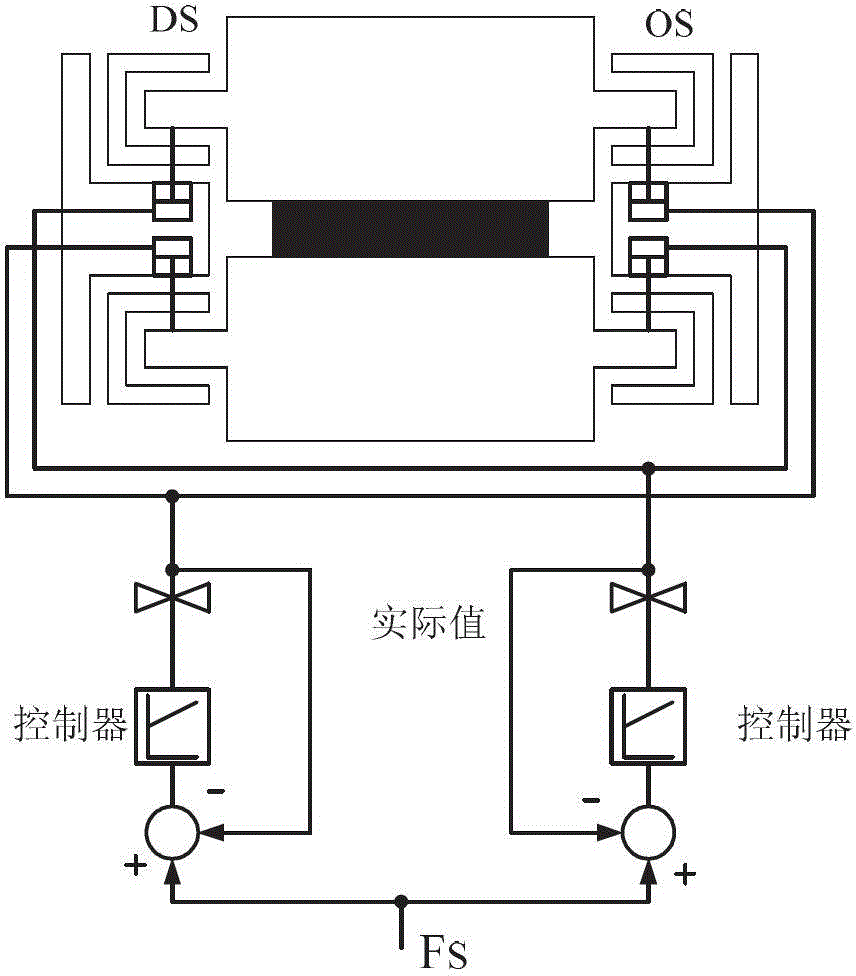

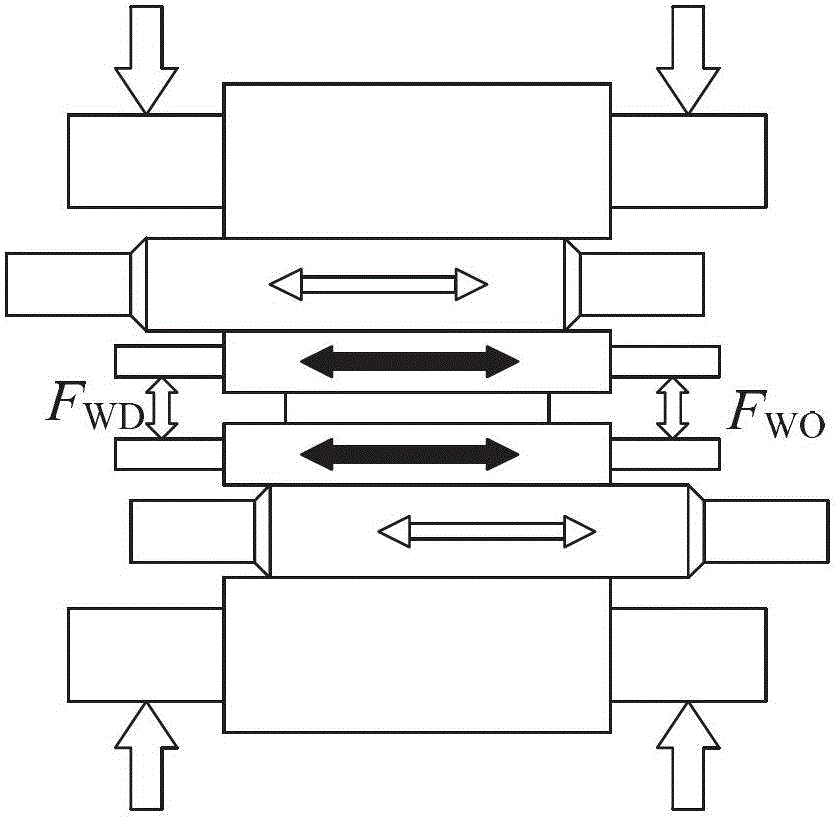

[0027] The work roll differential bending method used to control asymmetric shape defects, through differential adjustment of the bending force on both sides of the work roll, the difference in bending force will cause asymmetric changes in the shape of the roll gap to offset the asymmetric shape defects , mainly includes the steps of realizing the differential bending of the work roll and the determination of the initial value of the efficiency coefficient of the differential bending of the work roll, wherein:

[0028] 1) The implementation steps of work roll differential bending, see image 3 , Figure 4 , for HC and UC mills, if one wants to reduce the number of asymmetric shape defects, the practical and effective way is to differentially adjust the bending forces on both sides of the work rolls. The rolls are separately controlled individua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com