A porous bubble electrospinning device

A bubble electrospinning and high-voltage electrostatic technology, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as difficulty in controlling the uniformity of bubbles, incapable of industrial production, and great impact on performance. Increased output and production efficiency, low production cost, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

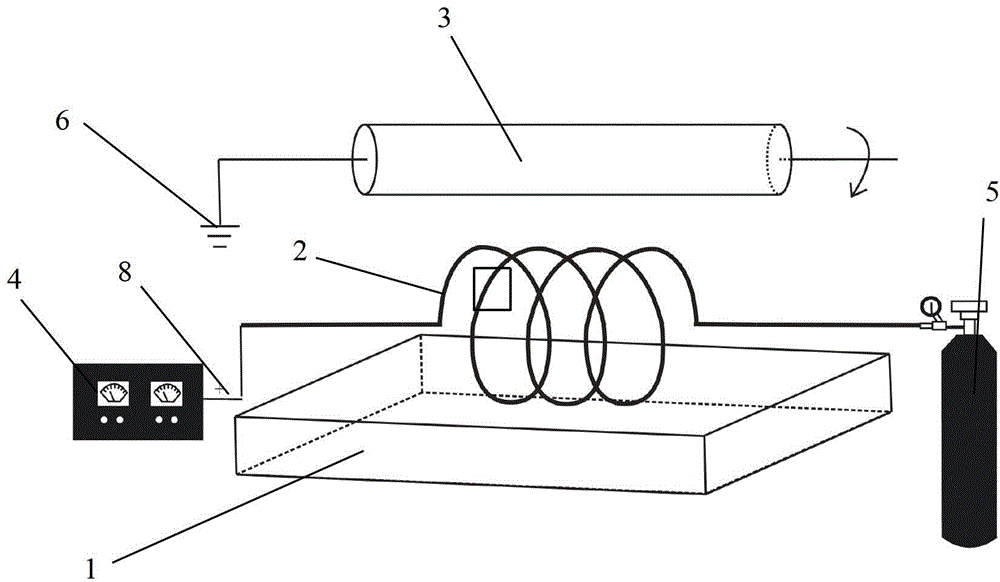

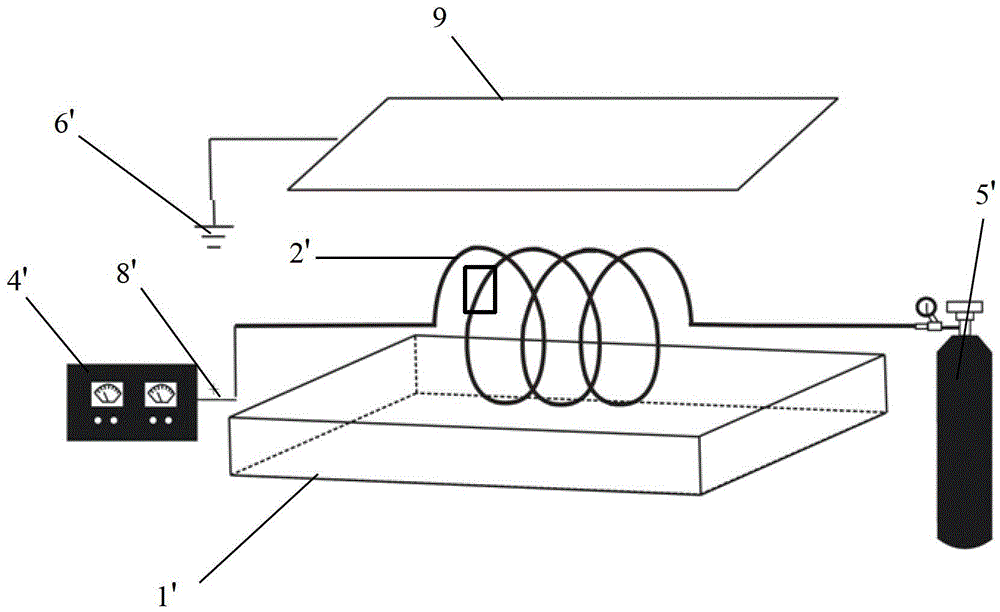

[0027] The invention discloses a porous bubble electrospinning device which can be used to produce nanofibers in large batches with high efficiency, so as to make up for the deficiencies and defects of the prior art and meet the needs of production and life.

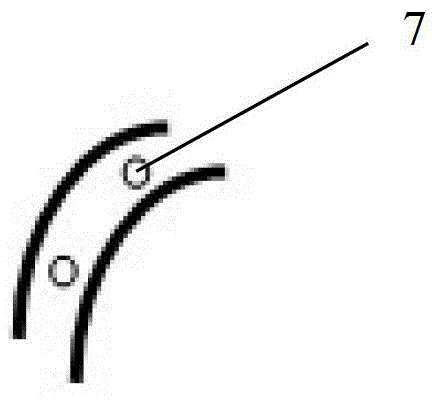

[0028] The porous bubble electrospinning device includes a liquid storage tank, a high-voltage electrostatic generator, an air pump, a receiving part arranged directly above the liquid storage tank, a metal electrode, and a ground electrode connected to the receiving part, and the upper end of the liquid storage tank Opening, the liquid storage pool is connected with the high-voltage electrostatic generator through the metal electrode, and a multi-coil rotating metal air guide tube is placed in the solution of the liquid storage pool, and the multi-coil rotating metal air guide tube is connected with the high-voltage static electricity generator through the metal electrode. The air pump is connected with the multi-coil ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com