Conductive polyaniline solvent-free anticorrosive coating not containing anti-rust pigments

A technology of conductive polyaniline and anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of easy whitening of the paint film, toxicity, and brittle paint film, so as to avoid the suspicion of heavy metals and the scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

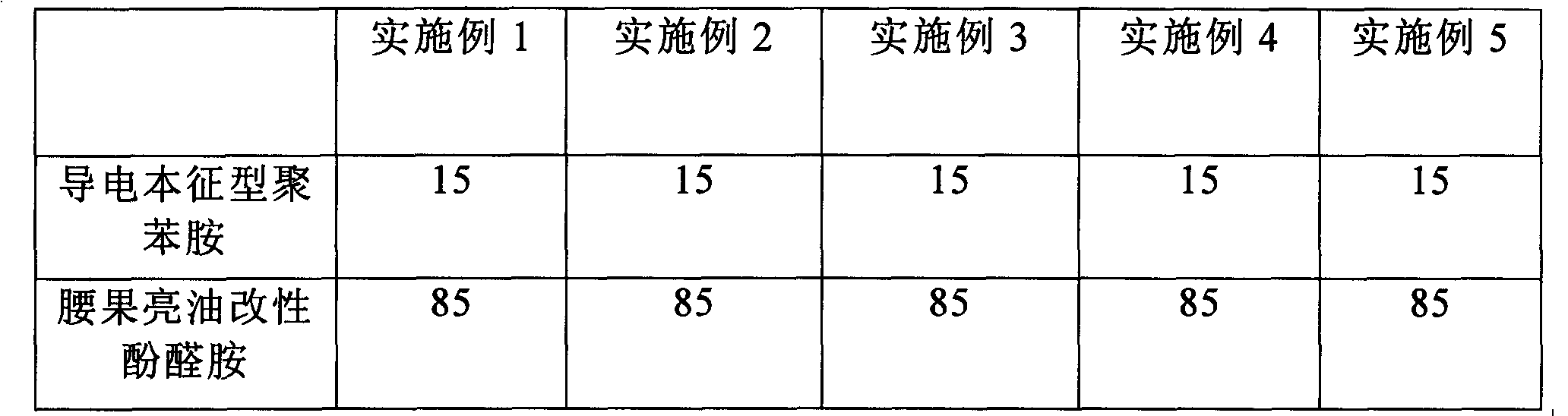

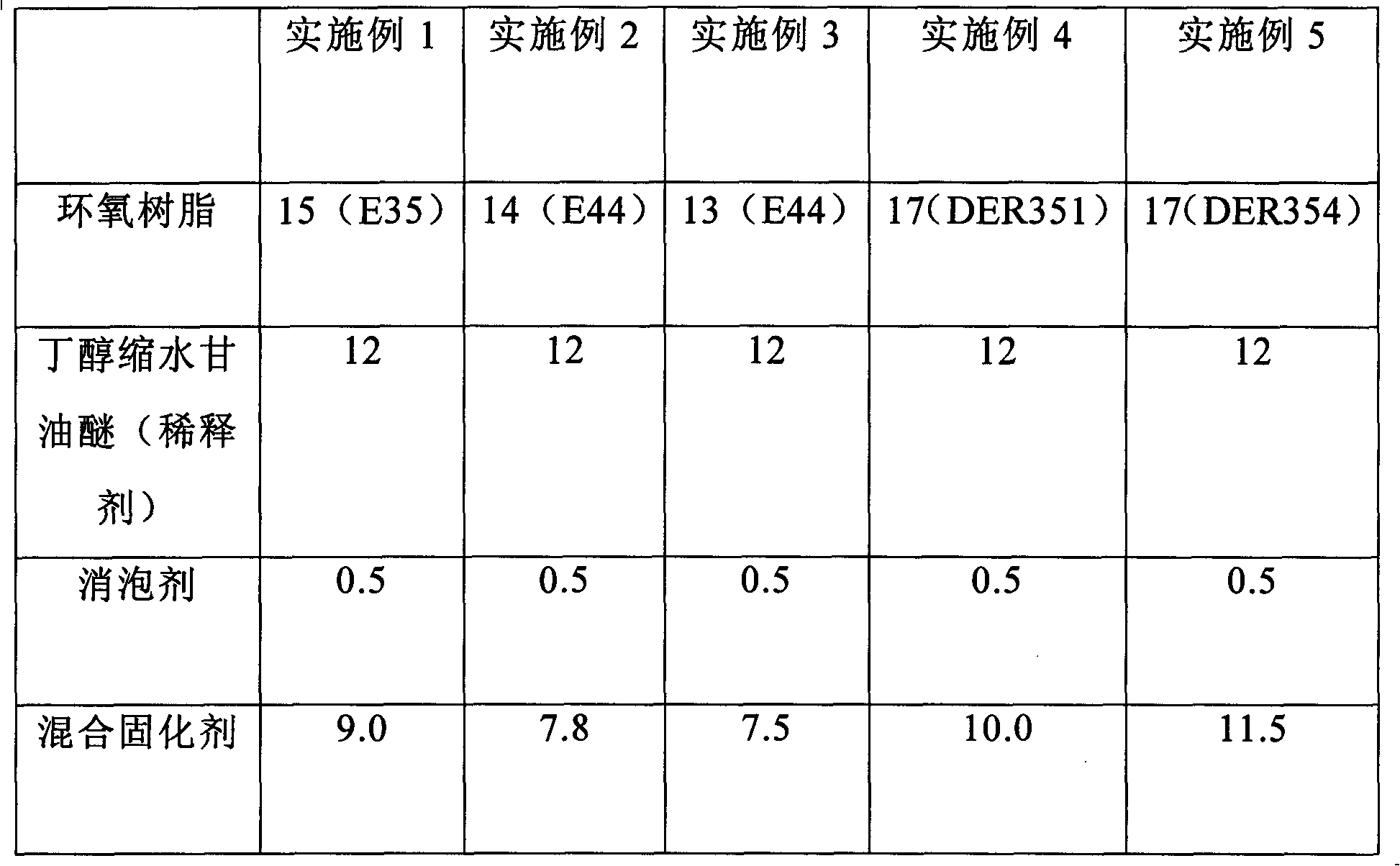

[0028] Dissolve the conductive intrinsic polyaniline in the parts by weight of Table 1 in the cashew varnish modified phenalkamine shown in Table 1, stir it with an electromagnetic stirrer for 2 hours to dissolve it, and then filter it with a glass funnel to prepare Mixed curing agent, stand-by, take by weight the epoxy resin of the weight part of table 2, add the diluent of the weight part shown in table 2, silicone oil, carry out electromagnetic stirring 2 hours, make it evenly mix, then add above-mentioned table 2 The mixed solidifying agent of two shown weight parts, stir (2 hours) with electromagnetic stirrer and stand still for 1 hour, the coating that this is made is with paintbrush or spray on No. 45 steel plates after the treatment, with this preparation Coating is applied on the treated steel plate with a paintbrush or spray gun to keep its thickness at 15-250 microns. Curing at room temperature for 8-24 hours to obtain a uniform, transparent and tough dark blue coat...

Embodiment 5

[0034]

[0035] Conductive polyaniline solvent-free anti-corrosion coating without anti-rust pigment, the coating includes the following components and content by weight: mixed curing agent 30kg, epoxy resin 10kg, diluent 10kg, defoamer 0.3kg, wherein, mixed curing The agent is obtained by mixing intrinsically conductive polyaniline and curing agent at a weight ratio of 10:90.

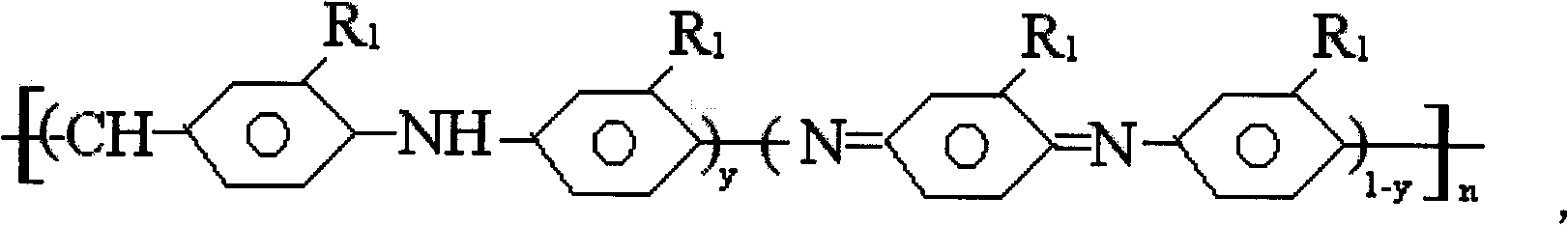

[0036] The molecular formula of intrinsic conductive polyaniline is:

[0037]

[0038] where y is 0 and R1 is CH 6 O, n is 50, the curing agent is cashew varnish modified phenalkamine, the epoxy resin is bisphenol A type epoxy resin, the diluent is glycidyl ether of isopropanol, and the defoaming agent is fatty acid alkyl ester of C3.

[0039] When synthesizing, take the polyaniline in the intrinsic state and add it to the modified phenalkamine under the stirring of an electromagnetic stirrer to dissolve, stir for 2-4 hours and filter to make a mixed curing agent;

[0040] Weigh the epoxy resin...

Embodiment 6

[0043] Conductive polyaniline solvent-free anti-corrosion coating without anti-rust pigment, the coating includes the following components and content by weight: mixed curing agent 35kg, epoxy resin 15kg, diluent 30kg, defoamer 1kg, wherein, mixed curing agent It is obtained by mixing intrinsically conductive polyaniline and curing agent at a weight ratio of 15:85.

[0044] The molecular formula of intrinsic conductive polyaniline is:

[0045]

[0046] Where y is 0 and R1 is C 3 h 8 O, n is 80. The curing agent is cashew varnish modified phenalkamine, the epoxy resin is bisphenol F epoxy resin, the diluent is polypropylene glycol glycidyl ether, and the defoaming agent is oligomeric polyoxyethylene.

[0047] When synthesizing, take the polyaniline in the intrinsic state and add it to the modified phenalkamine under the stirring of an electromagnetic stirrer to dissolve, stir for 2-4 hours and filter to make a mixed curing agent;

[0048] Weigh the epoxy resin according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com