Direct current high voltage high frequency pulse dual-pole corona grating static coagulation dust removal device

A high-frequency pulse, DC high-voltage technology, applied in electrostatic separation, external electrostatic separator, electrode structure, etc., can solve the problems of high risk, long condensation area, large initial investment in equipment, etc., to achieve high safety, structure Simple and cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

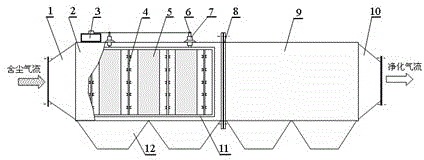

[0046] A DC high-voltage high-frequency pulse bipolar corona grid electrostatic coagulation and dust removal device. Such as figure 1 As shown, the device consists of an air intake box 1, an electrostatic condenser 2, an electrostatic precipitator 9 and an air outlet box 10. The air intake box 1 is fixedly connected to the inlet end of the electrostatic condenser 2, the outlet end of the electrostatic condenser 2 and the inlet end of the electrostatic precipitator 9 are directly fixedly connected by a flange 8, and the outlet end of the electrostatic precipitator 9 is connected to the air outlet box 10 fixed connections.

[0047] The structure of the electrostatic condenser 2 is as follows figure 2 As shown: high voltage pole frames 11 and ground pole frames 15 are provided in the shell of electrostatic condenser 2, there are 2 high voltage pole frames 11 and 3 ground pole frames 15. The high-voltage pole frame 11 and the ground pole frame 15 are parallel to each other, an...

Embodiment 2

[0056] A DC high-voltage high-frequency pulse bipolar corona grid electrostatic coagulation and dust removal device. This device is except following structure and technical parameter, all the other are the same as embodiment 1.

[0057] The outlet end of the electrostatic condenser 2 is fixedly connected to the inlet end of the electrostatic precipitator 9 through a pipeline;

[0058] The number of high-voltage pole frames 11 is 3 to 10, and the number of ground pole frames is one more than the number of high-voltage pole frames provided in the shell of the electrostatic condenser 2;

[0059] The total number of high-voltage pole lines 4 and high-voltage pole-shaped plates 5 is 9, or 11, or 13, and the number of high-voltage pole lines 4 in each high-voltage pole frame 11 is one more than the number of high-voltage pole-shaped plates 5;

[0060] The total number of grounding pole plates 13 and grounding pole lines 14 is 9, or 1, or 13;

[0061] The high voltage pole line 4 a...

Embodiment 3

[0063] A DC high-voltage high-frequency pulse bipolar corona grid electrostatic coagulation and dust removal device. Such as image 3 As shown, the device consists of an air intake box 1, an electrostatic condenser 2, an electrostatic precipitator 9 and an air outlet box 10. The air intake box 1 is fixedly connected to the inlet end of the electrostatic condenser 2, the outlet end of the electrostatic condenser 2 and the inlet end of the electrostatic precipitator 9 are directly fixedly connected by a flange 8, and the outlet end of the electrostatic precipitator 9 is connected to the air outlet box 10 fixed connections.

[0064] The structure of the electrostatic condenser 2 is: a high-voltage pole frame and a grounding pole frame are arranged in the shell of the electrostatic condenser 2, and the number of the high-voltage pole frame is 11 to 15, and the number of the grounding pole frame is more than that in the shell of the electrostatic condenser 2 The number of high-vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com