CNC lathe controller capable of automatically setting thread retracting distance and angle

An automatic setting and controller technology, used in automatic control devices, manufacturing tools, metal processing equipment, etc., can solve problems such as low production efficiency, difficult setting of retraction distance and retraction angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

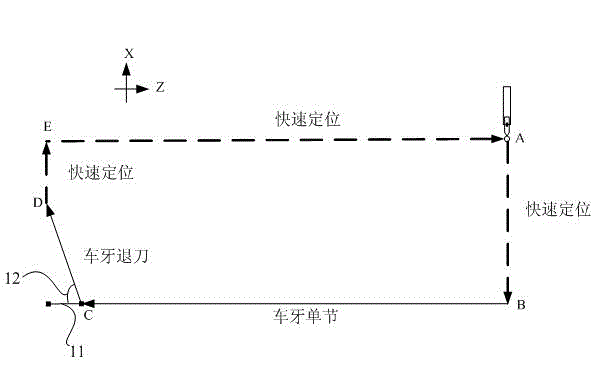

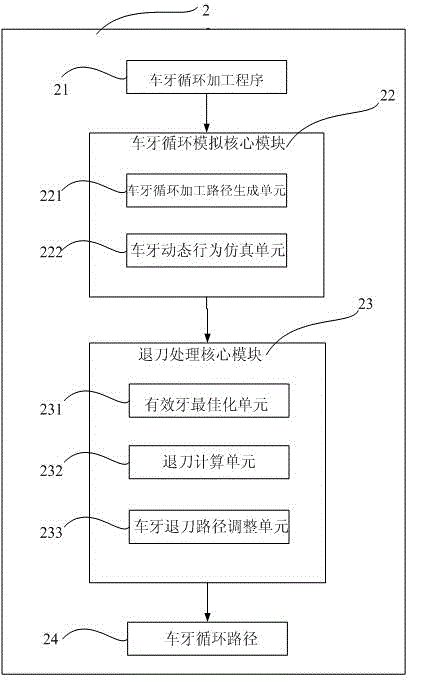

[0015] A CNC lathe controller with automatic setting of the retracting distance and angle of the turning teeth, such as figure 2 As shown, the controller 2 includes at least a turning thread cycle simulation core module 22 and a tool withdrawal processing core module 23, and the turning thread cycle simulation core module 22 includes a turning thread cycle processing path generation unit 221 and a turning thread dynamic behavior simulation unit 222, Before the actual turning action is performed, the dynamic simulation is performed by the turning tooth cycle processing path generation unit 221 and the turning tooth dynamic behavior simulation unit 222, so as to control the dynamic behavior of the actual turning workpiece; wherein, the turning tooth cycle processing path generation unit 221 will The input turning cycle processing program 21 is interpreted into the actual cutting cycle path, and the cutting dynamic behavior simulation unit 222 uses the speed input by the user acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com