High-molecular polymer based resistance type humidity sensor and manufacturing and testing method thereof

A high-molecular polymer and humidity sensor technology, applied in the direction of material resistance, etc., to achieve the effect of strong designability, simple preparation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

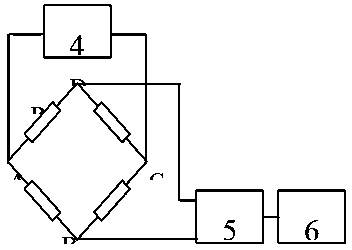

Method used

Image

Examples

Embodiment 1

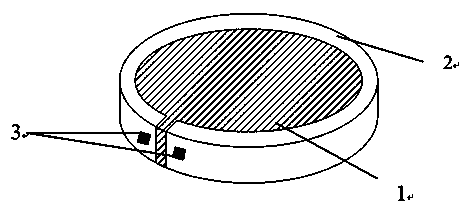

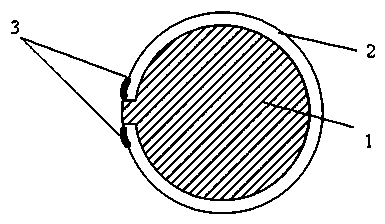

[0045] Prepare a sensor with a diameter of 5mm and a thickness of 2mm:

[0046] The first step is to prepare the moisture-sensitive material layer 1:

[0047] Use the Nafion solution to solidify and form the moisture-sensitive material layer 1 according to the conventional method with the designed thickness.

[0048] Raw materials: Nafion solution, sec-butanol, dimethyl sulfoxide (DMSO)

[0049] a. According to the size of the moisture-sensitive material layer 1, the amount of Nafion solution used is 300 mL. Nafion DES 520cs, with a concentration of 5%wt, Nafion as a solute, and a 1:1 mixture of sec-butanol and water as a solvent, is dried to a concentration of 20-50%, and the temperature of the vacuum oven is controlled at 50-60°C.

[0050] b. Add an appropriate amount of DMSO dropwise into the solution (the volume ratio is DMSO:Nafion≈1:20~50) to prepare the casting solution. Then put the casting solution in an oven at 50-60°C until the surface is dry.

[0051] c. Raise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com