Micro-electromechanical systems (MEMS) microphone

A microphone and chip technology, applied in the field of microphones, can solve problems affecting product user experience, resource waste, reliability issues, etc., to reduce the risk of damage, prolong service life, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

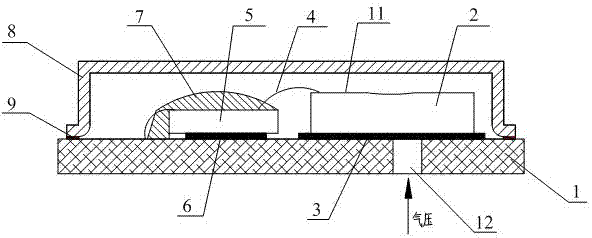

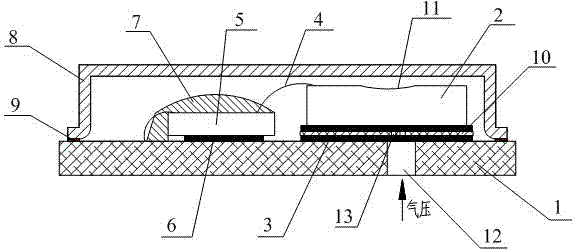

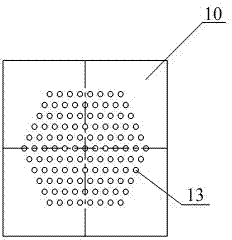

[0023] refer to figure 1 The structure schematic diagram of the existing MEMS microphone is shown, the existing MEMS microphone includes: a printed circuit board 1, a MEMS chip 2, an integrated circuit chip (Application Specific Integrated Circuit, ASIC) 5, a diaphragm 11, a microphone shell 8, a sound hole 12.

[0024] Wherein, the microphone housing 8 is combined with the printed circuit board 1 to form a cavity, and the ASIC chip 5 and the MEMS chip 2 are built in. The connection between the microphone housing 8 and the printed circuit board 1 is sealed with a sealant 9 , or with solder paste. The printed circuit board 1 is provided with a sound hole 12 . External sound pressure or air pressure triggers the diaphragm 11 on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap