Method for improving recovery efficiency of high-hydrocarbon-content gas deposit by high-CO2-content gas deposit

A recovery factor and hydrocarbon gas technology, which is applied in the field of improving the recovery rate of high hydrocarbon-bearing gas reservoirs, can solve the problems of high investment cost, high cost and high anti-corrosion requirements of drilling and completion and production facilities, so as to reduce development costs and CO2 emissions, increased formation pressure, considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

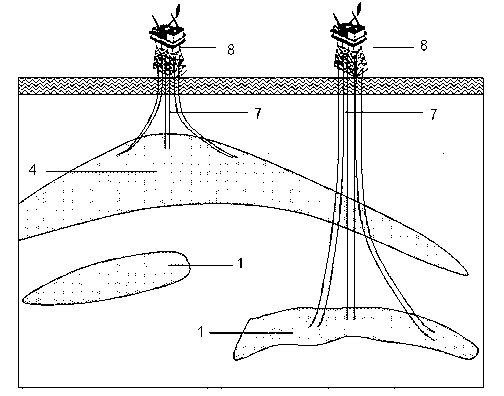

Image

Examples

Embodiment Construction

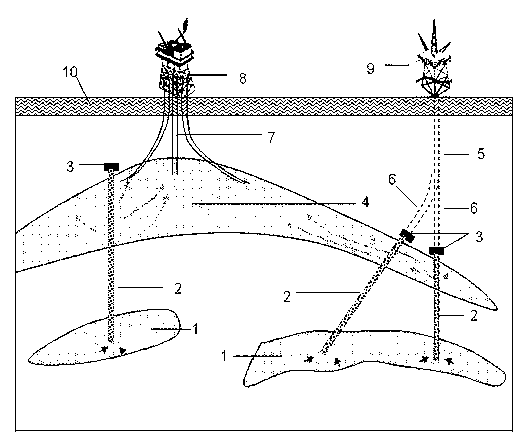

[0028] as attached figure 2 As shown, using high CO 2 A method for increasing the recovery rate of a gas reservoir with high hydrocarbon content, comprising the following steps:

[0029] 1) At the appropriate stage of offshore gas field development, select a depleted high-hydrocarbon gas reservoir 4 with medium-high permeability, that is, a permeability > 10mD, and a relatively stable distribution, from the developed gas field. Around the high hydrocarbon-bearing gas reservoirs, select the selected high CO-containing gas pools to be developed that are suitable for the development method of the present invention 2 gas reservoir 1;

[0030] 2) According to the selected high CO content to be developed 2 The spatial relationship between the gas reservoir 1 and the developed high hydrocarbon content gas reservoir 4, put the drilling ship 9 in place at the appropriate ground position, and drill to the seabed to form the construction well 5;

[0031] 3) In the construction well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com