Hot air heating furnace

A heating furnace and hot air technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of uneven temperature, low plant yield, and no air flow, and achieve the effect of uniform temperature in the shed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

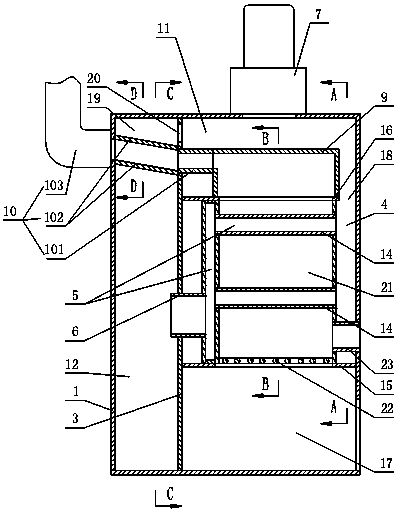

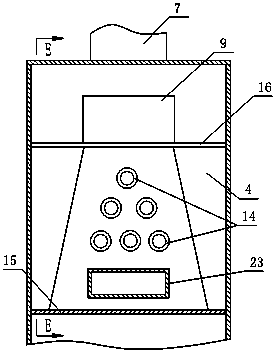

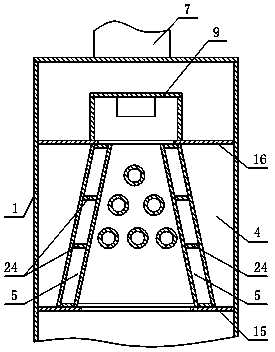

[0022] The hot air heating stove shown in the figure includes a furnace box body 1, which is a box body composed of a bottom wall, a top wall, and surrounding side walls. The fuel-adding part is described as the front of the heating furnace , The furnace box 1 is equipped with a horizontally arranged vertical partition 3, which divides the inner cavity of the furnace box 1 from front to back into the furnace body installation chamber 11 and the hot air discharge chamber 12. The furnace body installation chamber 11 is equipped with a furnace The furnace body installation chamber 11 is equipped with a horizontally arranged lower partition 15 and an upper partition 16 from bottom to top. The furnace body is installed on the lower partition 15, and the lower partition 15 is provided with ash leakage corresponding to the grate. The space between the lower partition 15 and the bottom wall of the furnace box body is the ash chamber 17. The upper partition plate 16 is flush with the top...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap