Domestic sludge drying treatment method

A domestic sludge and formula technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of poor effect, high cost, low processing capacity, etc., and achieve the effect of simple operation, sufficient source, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

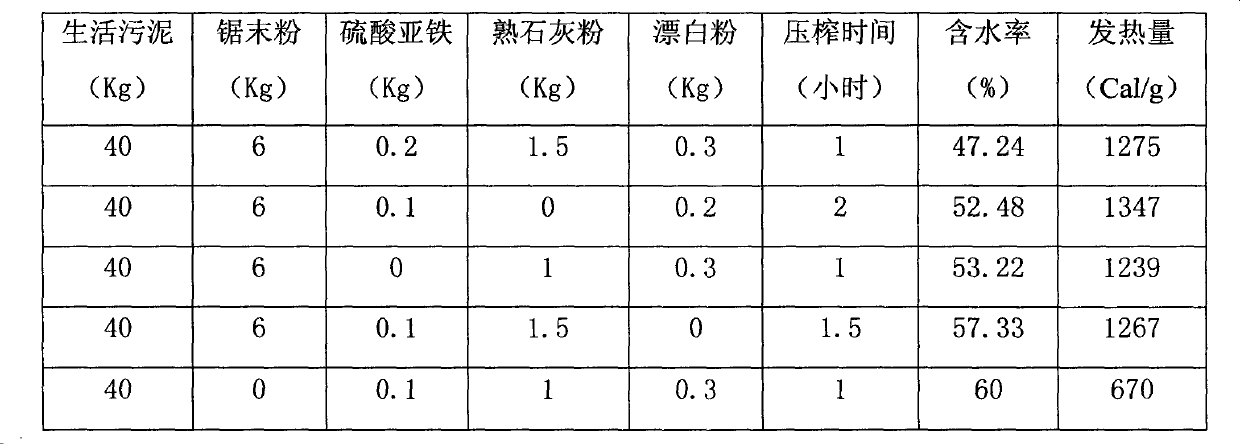

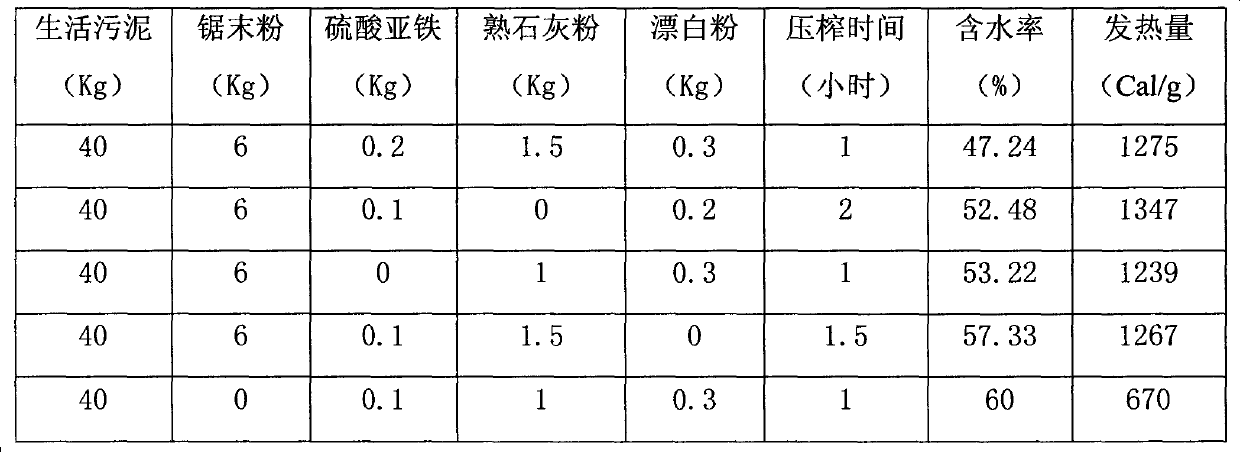

[0019] The technical solutions of the present invention will be further specifically described below through examples.

[0020] In this embodiment, a method for drying domestic sludge is to put 40Kg of domestic sludge with a water content of 75% into the stirring tank, add 400Kg of water, add a mesh number of 30 mesh, a water content of 48%, and a calorific value of 1778Cal / 6Kg sawdust powder of g, add 0.2Kg ferrous sulfate, 1.5Kg slaked lime powder and 0.3Kg bleaching powder, stir well. The prepared polyacrylamide is cationic polyacrylamide with an ionization degree of 35 and a molecular weight of 8 million. The polyacrylamide solution is 3 kg and the concentration is 0.26%, that is, the polyacrylamide is 7.8 g.

[0021] After sampling, the solid content of the sludge was measured to be 9.7%, and then the sludge and the prepared polyacrylamide solution were pumped into the filter press with a pneumatic diaphragm pump. The filter plates of the filter press were all made of 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com