Common rail fuel system for a multi-cylinder bank combustion engine with independently controlled fuel supply to each bank

A fuel supply system, fuel system technology, applied in the direction of fuel injection control, charging system, engine components, etc., can solve problems such as rise and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

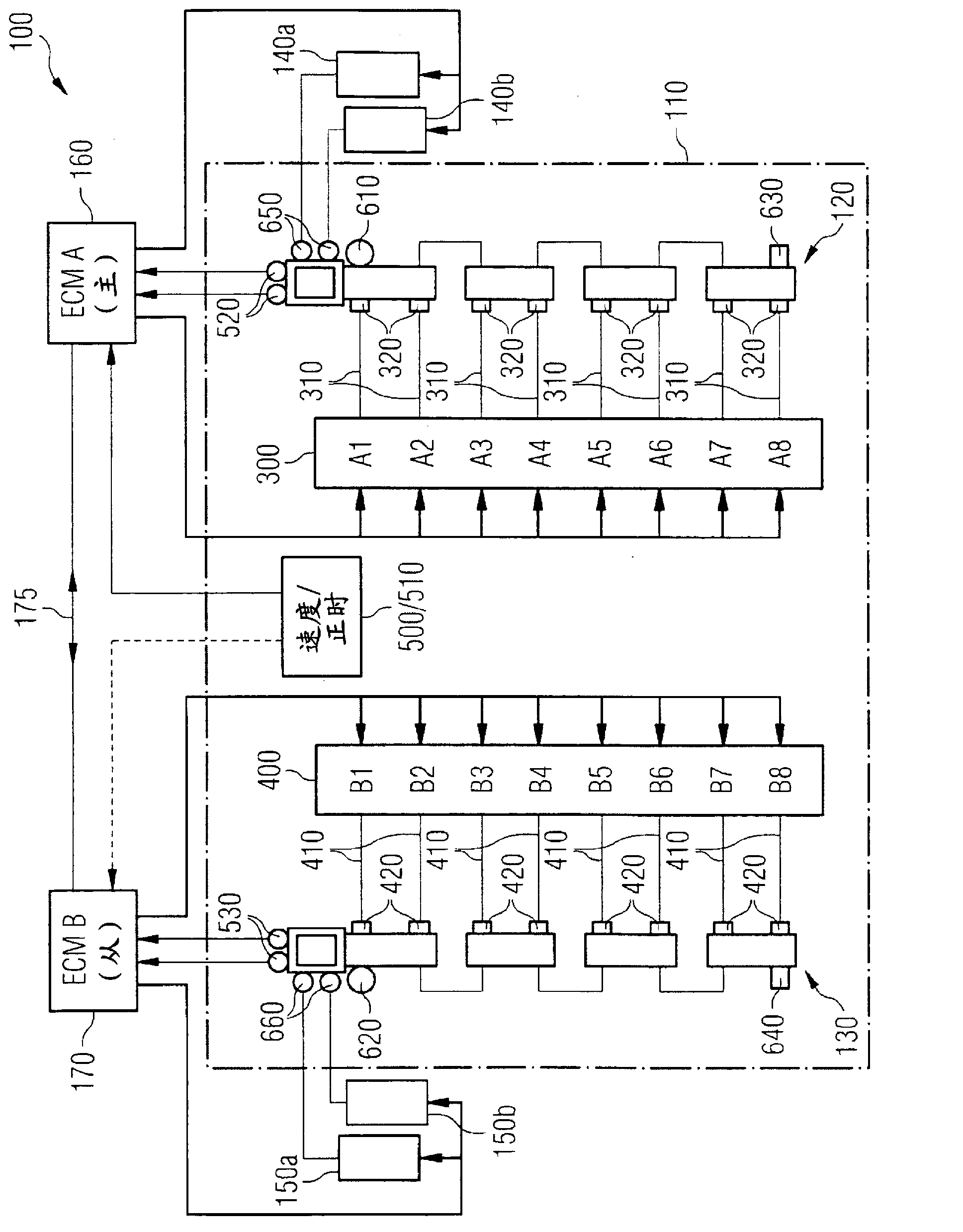

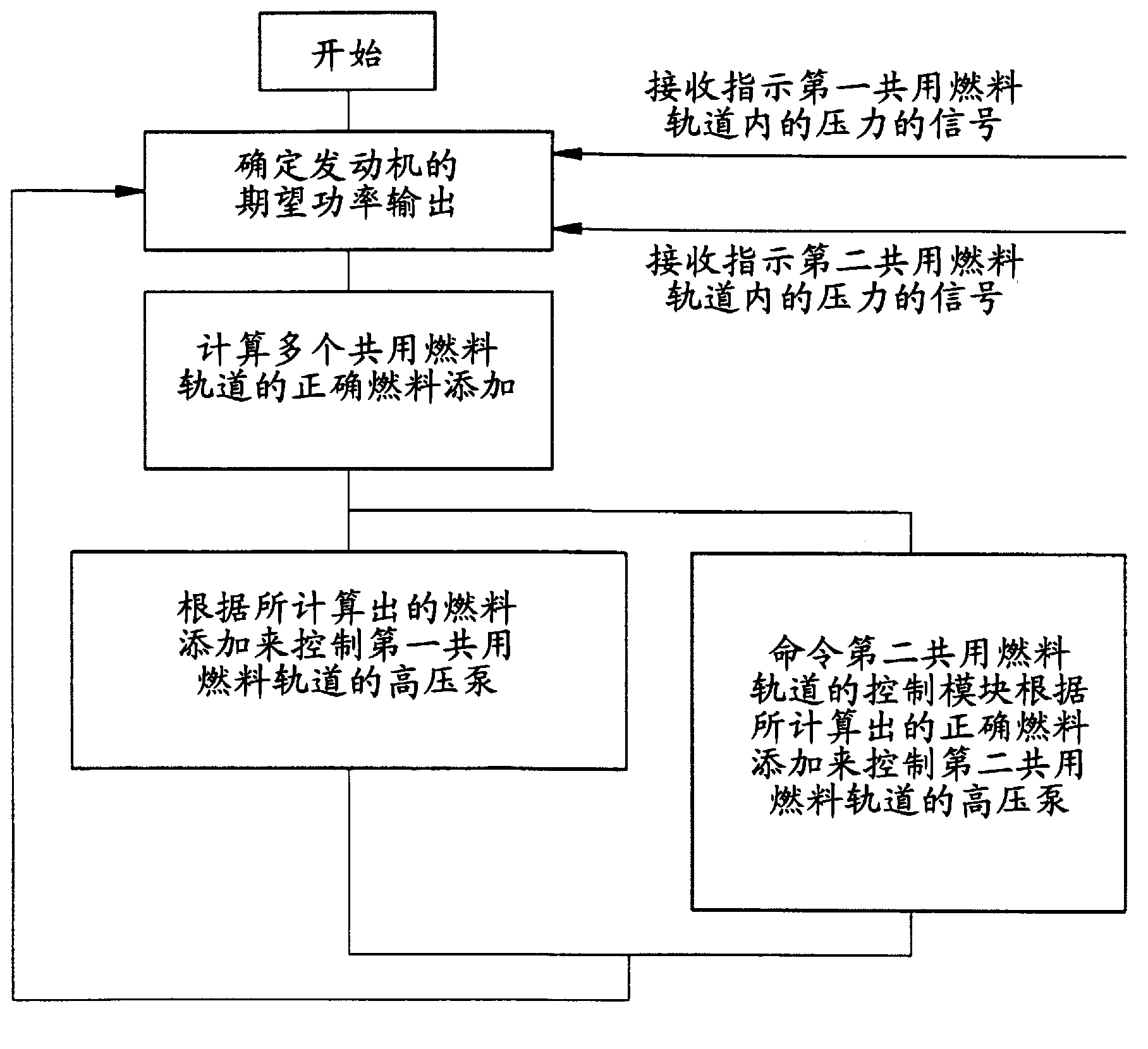

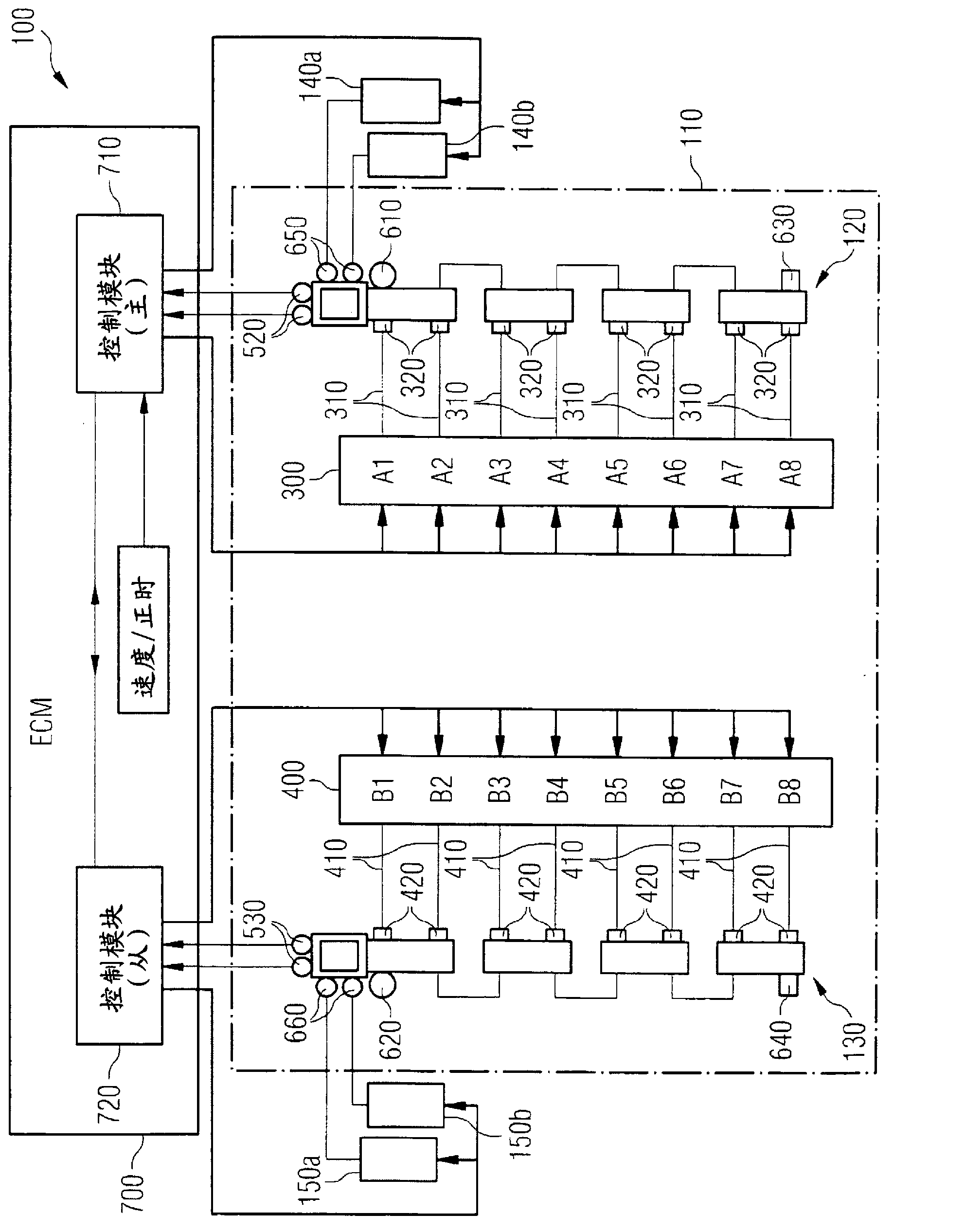

[0028] refer to figure 1 , an exemplary embodiment of the fuel supply system 100 according to the present invention is described in more detail. Such a fuel supply system 100 may be used for medium to large size internal combustion engines 110 . In particular, the internal combustion engine 110 may be sized and configured such that it is used, for example, in a boat, larger ship, or power plant. An internal combustion engine of this size may have a power output in excess of 500 kW / cylinder with 12 to 20 cylinders.

[0029] The fuel supply system 100 may be used in an internal combustion engine 110 having at least two separate cylinder banks 300 , 400 . Each cylinder bank 300 , 400 may include a plurality of cylinders 310 , 410 . Each cylinder 310 , 410 may be equipped with at least one fuel injector 320 , 420 . Each of these fuel injectors 320 , 420 may be connected to an associated common fuel rail 120 , 130 .

[0030] As mentioned above, each cylinder bank 300 , 400 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com