A kind of synthetic method and application of the palladium nanoparticle of polymer microsphere immobilization

A polymer and palladium nanotechnology, applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, hydrocarbons, etc., can solve the problem of low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

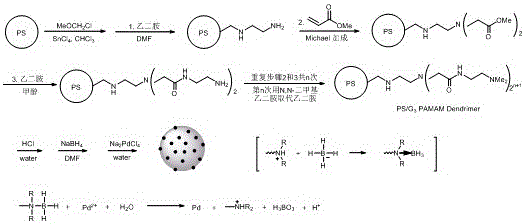

Method used

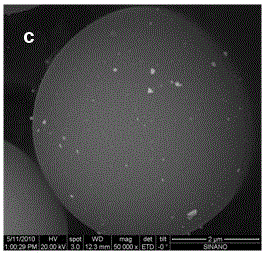

Image

Examples

Embodiment 1

[0043] Preparation of 5 μm matrix material microspheres, that is, the polymer core of the composite microspheres:

[0044] Take 32.8g of 26.0% polystyrene seed suspension aqueous solution with a particle size of 1.9 μm, 450g of deionized water, and 0.23g of 10% sodium dodecylbenzenesulfonate aqueous solution into a 2000mL four-necked round-bottomed flask, blow in nitrogen, and stir Then heated to 60°C. Take 15.0g of divinylbenzene, 135.0g of styrene, 10.7g of 10% sodium dodecylbenzenesulfonate aqueous solution, and 165g of deionized water, mix them with a homogeneous mixer, and add them to a four-necked round-bottomed flask. After stirring for 2 hours, the temperature was lowered to 40°C, and 0.2g of 30% hydrogen peroxide was added. Take 1.1g of tert-butyl hydroperoxide, 0.3g of 10% sodium dodecylbenzenesulfonate aqueous solution, 65g of deionized water, mix them with a homogeneous mixer, add them to a four-neck round bottom flask, and then add 56.3g of 20% polyethylene Pyrr...

Embodiment 2

[0046] Chloromethylation of microspheres in Example 1 generates chloromethyl groups on the outside of the microspheres, that is, chloromethylation of polystyrene-divinylbenzene microspheres:

[0047] 10.0 g of the microspheres in Example 1 and 100 mL of anhydrous chloroform were added into a 250 mL three-necked flask, and mechanical stirring was used to disperse the microspheres in the chloroform. The dispersed microspheres were stirred (120 rpm) at 0 °C for 1 hour, 1.7 mL of anhydrous tin tetrachloride was added, and after stirring for 5 minutes, 8.0 mL of chloromethyl ether was added dropwise. After the dropwise addition was completed, the reaction system was maintained at 0° C. and stirred for 30 minutes, then heated to 30° C. and continued to stir for 3 hours. After the reaction, the microspheres were filtered with a sand core funnel to remove the solution, and then the microspheres were washed with 200 mL of the following solvents in sequence: deionized water, 5% hydrochl...

Embodiment 3

[0049] Amination Example 2 microspheres form the first generation of microspheres with a dendritic structure on the outside, that is, the first step, amination of the chloromethylated polystyrene-divinylbenzene microspheres as the carrier:

[0050] Add 10.0g of microspheres and 140mL of N,N-dimethylformamide in Example 2 into a 250mL three-necked flask, stir mechanically to disperse the microspheres, add 25.0mL of ethylenediamine, and stir the system at 80°C for 16 hours . After the reaction, the microspheres were filtered with a sand core funnel to remove the solution, and then the microspheres were washed with ethanol and acetone in turn, and the washed microspheres were dried in an oven at 60°C for 12 hours to obtain the first-generation aminated microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com