Pressure-resistant gear oil tank for compression machinery

A fuel tank, pressure-resistant technology, applied in mechanical equipment, liquid variable capacity machinery, machines/engines, etc., can solve the problems of poor heat dissipation capacity of the lower part, low overall strength, small oil storage capacity, etc., to enhance thermal conductivity, The effect of strengthening the heat dissipation area and reducing the thickness of the inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

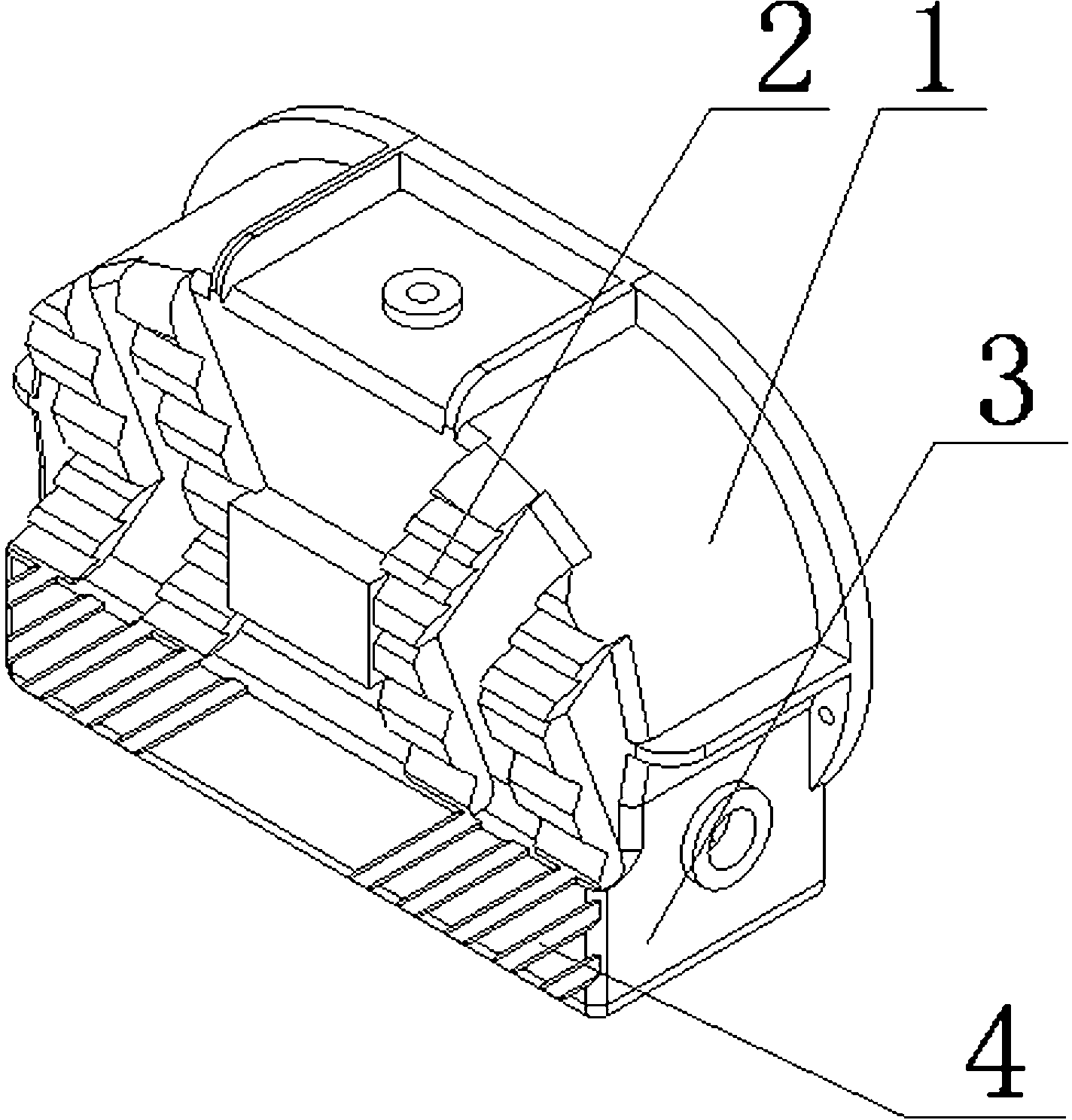

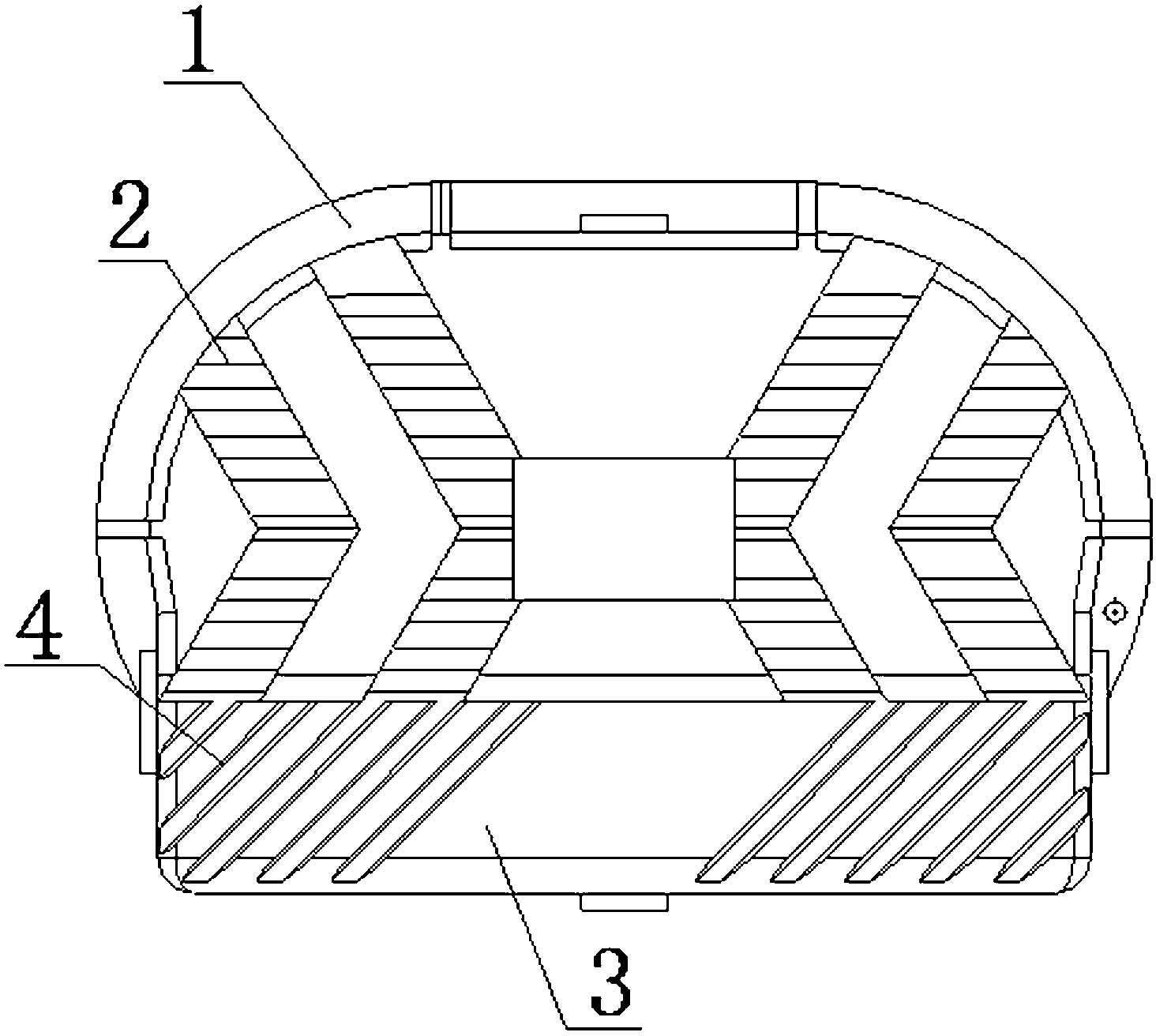

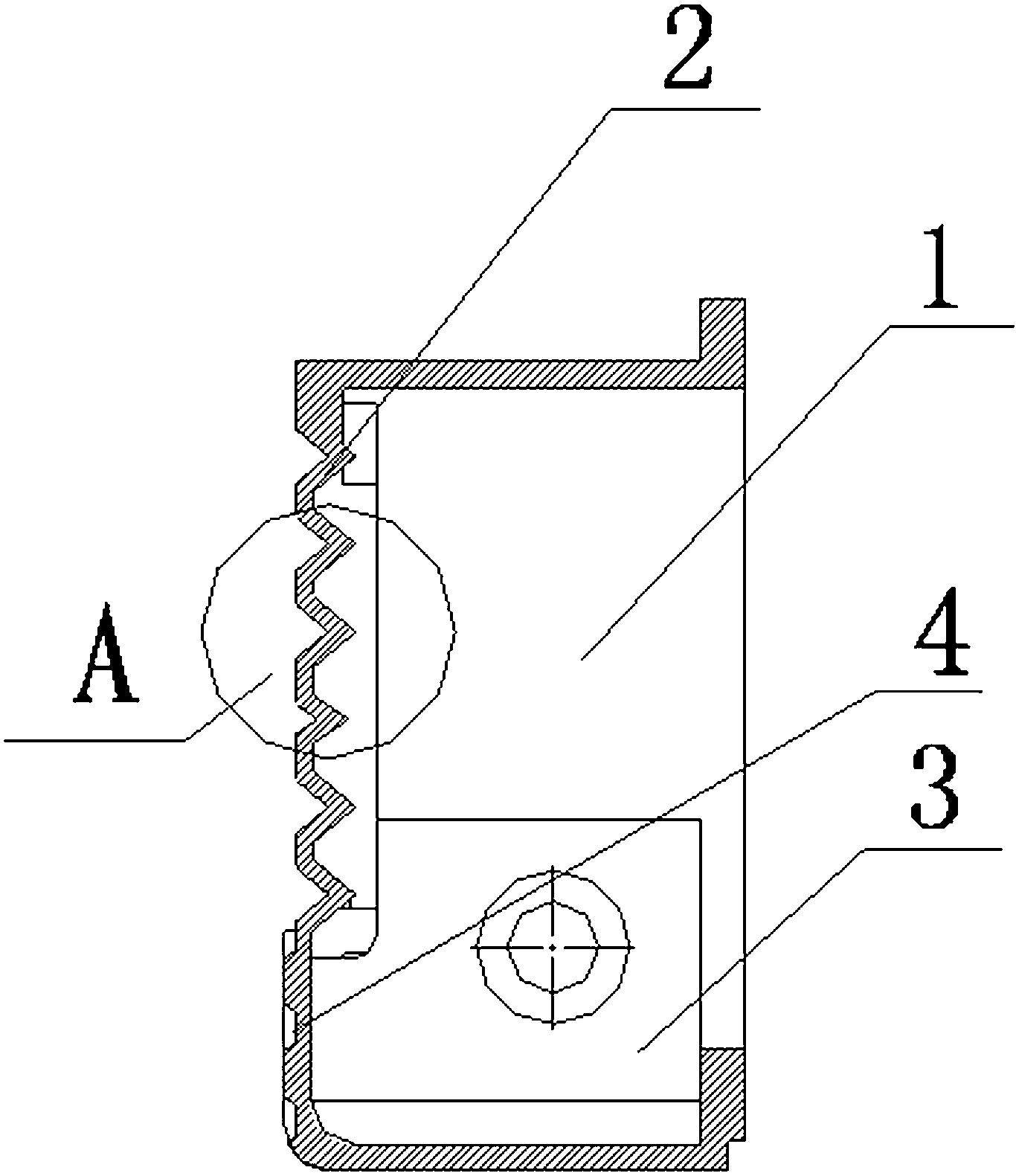

[0014] Such as Figure 1 to Figure 4 As shown, a pressure-resistant gear oil tank for compression machinery of the present invention includes an oil tank 1, the outer surface of the oil tank 1 is provided with a convex "X"-shaped reinforced heat pipe 2, and the bottom of the oil tank 1 is additionally provided with a heat-conducting The pipe 2 is of the same height as the oil storage chamber 3 , and the outer surface of the oil storage chamber 3 is provided with folds 4 . The heat pipe 2 and the oil storage chamber 3 protrude to the same height, and the surface of the oil tank 1 is still a plane, which is convenient for processing; the oil storage chamber 3 added at the bottom can effectively increase the oil storage capacity of the oil tank 1; the heat pipe 2 connects the oil tank 1. The surface is divided into several small surfaces, which has the strengthening effect of multiple complex folded edges. It has high strength and strong pressure, so the thickness of the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com