Special welding machine for iron core ejector rod

A welding machine and ejector technology, applied in welding equipment, resistance welding equipment, resistance electrode bases, etc., can solve the problems of uncontrollable coaxiality, unstable welding strength, high labor intensity, etc., and achieve good coaxiality, The effect of reducing labor intensity and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

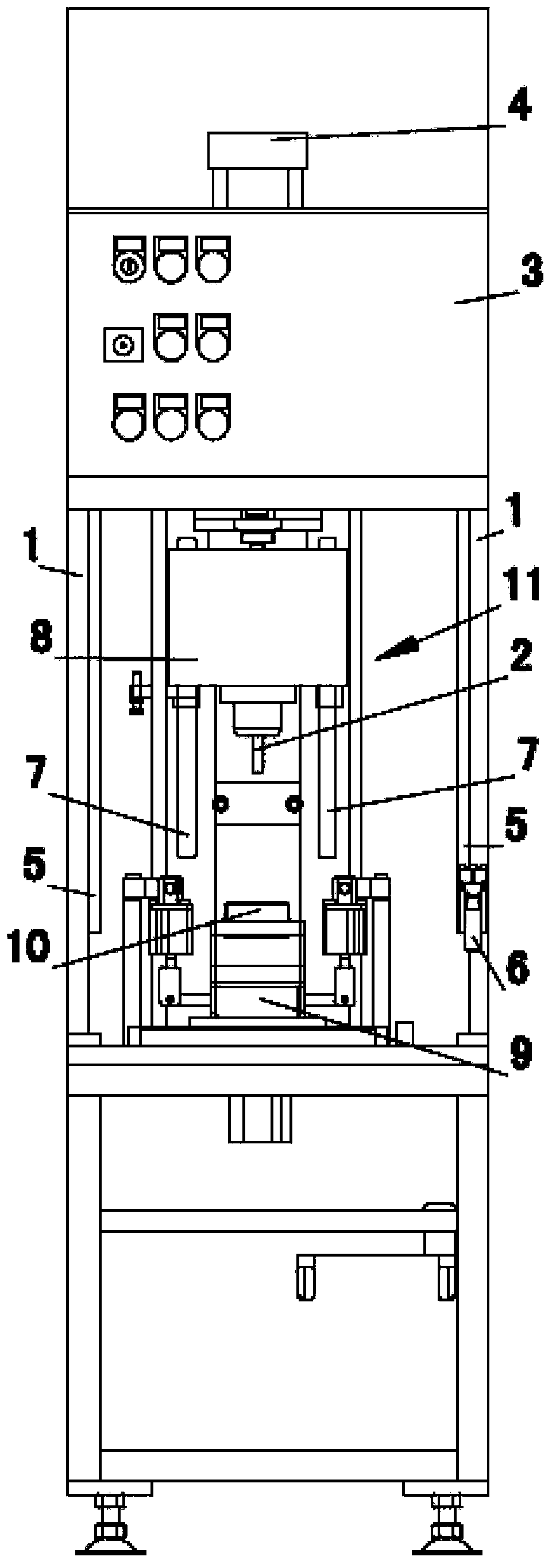

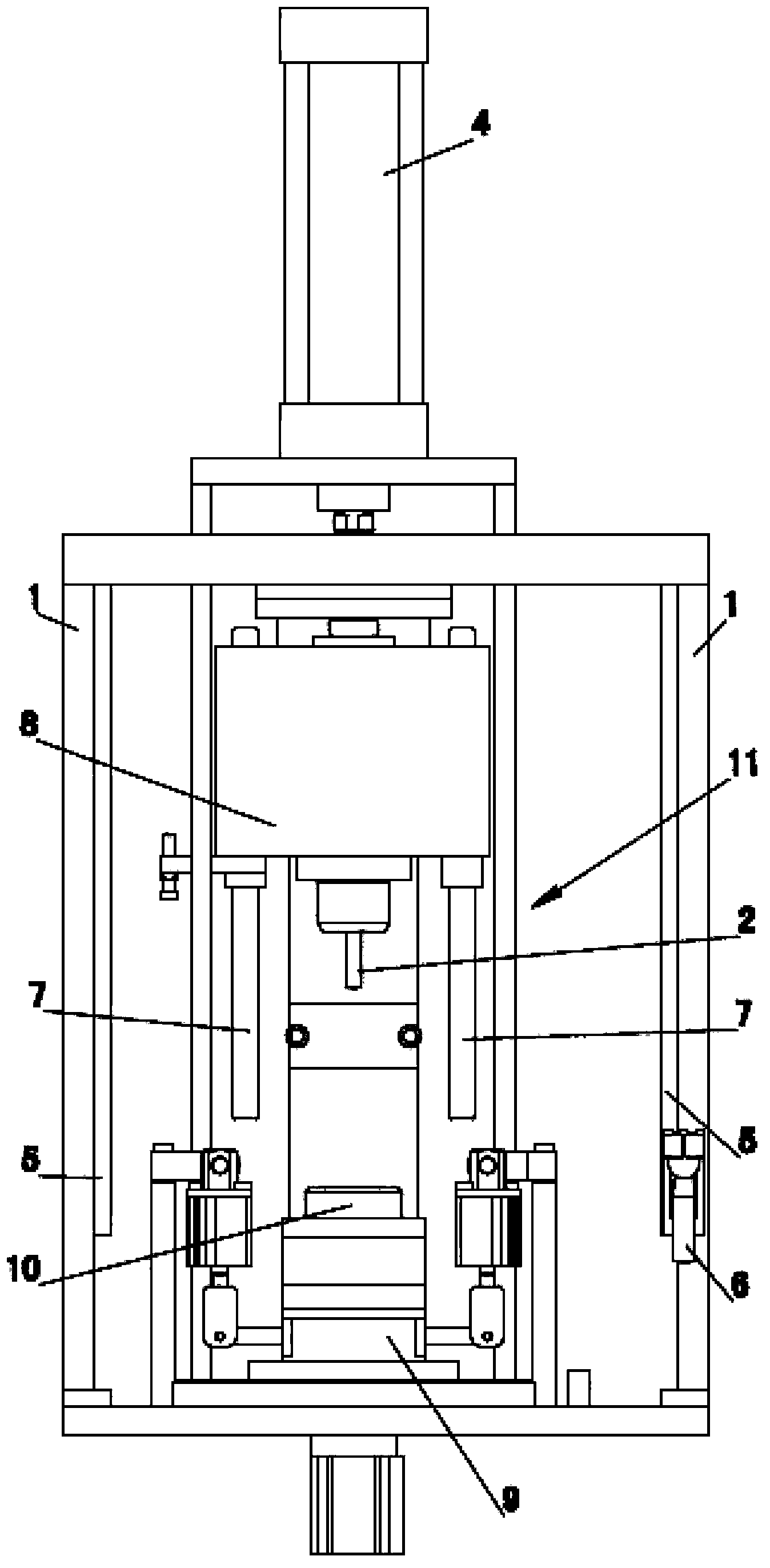

[0020] Such as Figure 1~2 Shown, a special welding machine for iron core mandrels, including a frame 1, a welding head 2, a mandrel clamping and ejecting mechanism 9, a base fixing mechanism 10, a guide positioning mechanism 11 and an electrode drive cylinder 4; the frame 1 A workbench 3 is arranged on it, and the ejector rod clamping and ejecting mechanism 9 is arranged on the workbench 3, and the base fixing mechanism 10 is arranged above the ejector rod clamping and ejecting mechanism 9; the guide The positioning mechanism 11 includes a slide rail 7 fixed on the frame 1, and a moving plate 8 slidingly connected with the slide rail 7; the welding head 2 is fixed on the moving plate 8; the welding head 2 faces the base fixing mechanism 10 Setting; the centers of the push rod clamping and ejecting mechanism 9, the base fixing mechanism 10 and the welding head 2 are on the same vertical line; the active end of the electrode driving cylinder 4 is relatively fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com