Novel internal combustion engine

A technology for internal combustion engines and engines, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problems of large sliding friction between the crankshaft journal and the connecting rod, wear and tear, etc., to reduce energy consumption and improve heat energy utilization efficiency and reduce carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

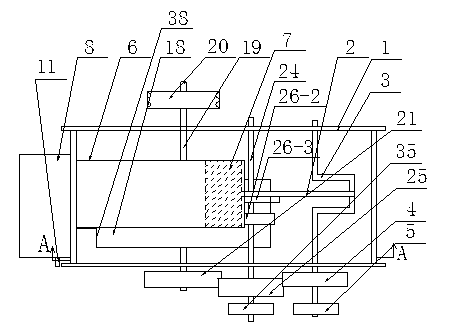

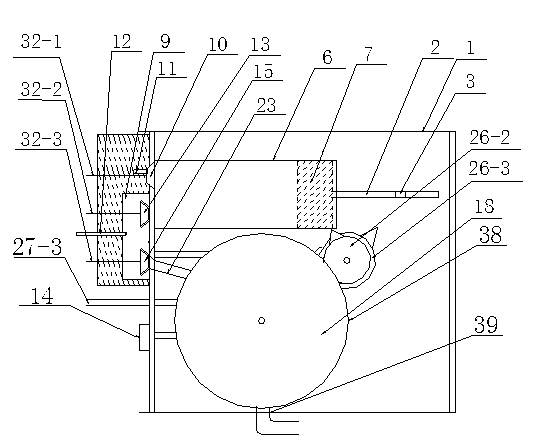

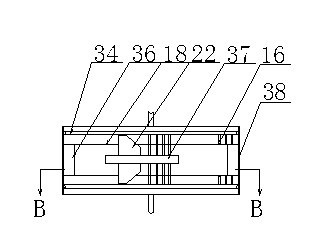

[0021] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9A new type of internal combustion engine shown includes a housing 1, a cylinder 6 and a crankshaft 3 are arranged in the housing, a connecting rod 2 is arranged at the end of the piston 7 in the cylinder 6, and the end of the connecting rod 2 is hinged with the crankshaft 3, Crankshaft 3 is fixed on the front and rear walls of the housing through bearings, crank gear 4 and crank cam 5 are arranged on the crankshaft outside the front wall of the housing, cylinder head 8 is arranged on the left side wall of the housing, and cylinder head 8 is provided with The combustion chamber 9, the cylinder head 8 are provided with an intake passage 11 and an oil inlet passage 12, the intake passage 11 communicates with the cylinder head through the intake valve 10, the oil inlet passage 12 communicates with the combustion chamber, and the cylinder head is also provided ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap