Full fluffy gold stamping composite fabric

A technology of composite fabrics and fluff, which is applied in the field of textile fabrics and fabrics, can solve the problems of poor layering, and achieve the effect of enhancing layering, ensuring warmth retention, and fullness of the fabric surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

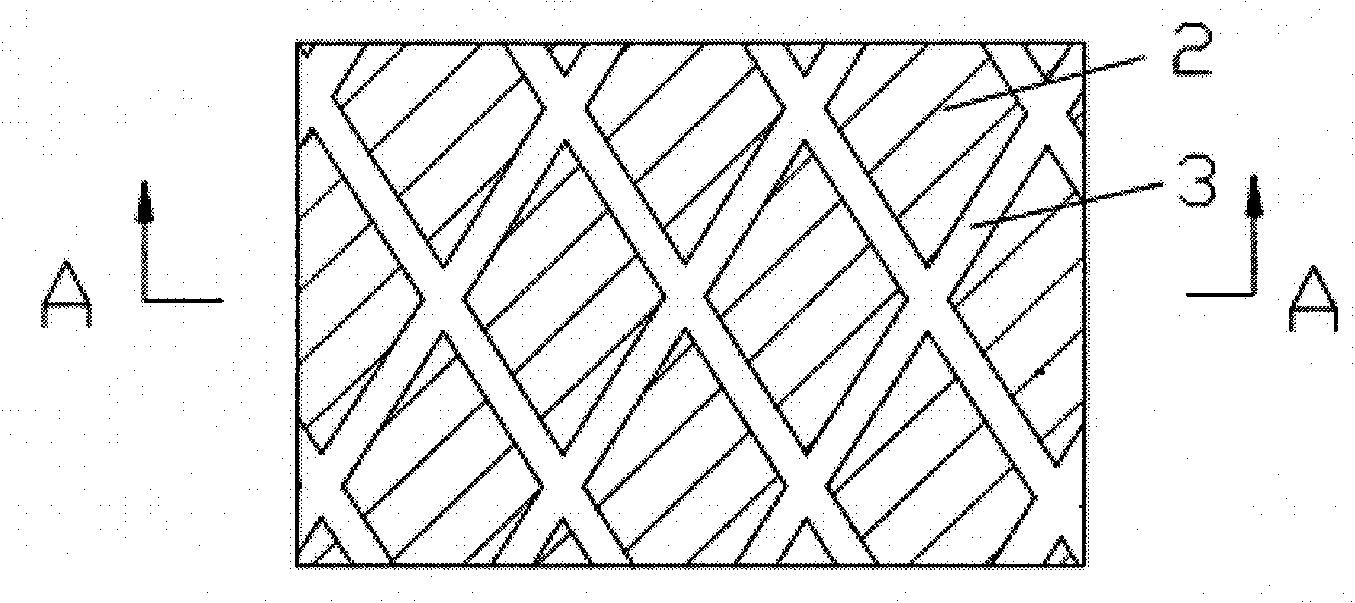

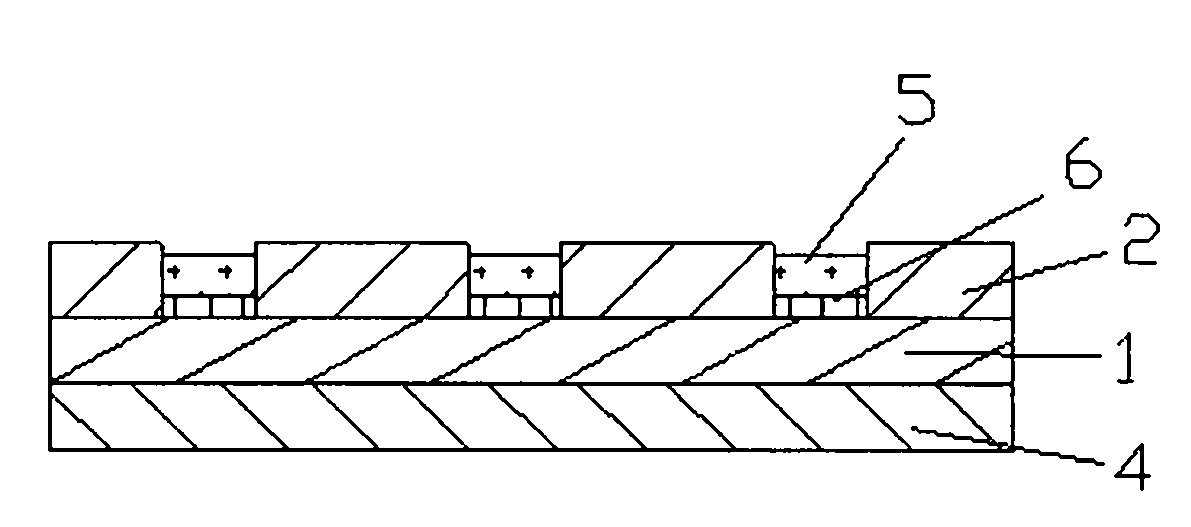

[0017] See figure 1 with figure 2 , The present invention relates to a plump pile bronzing composite fabric, comprising a fabric body 1, the fabric body is interwoven by warp yarns and weft yarns in a plain weave, the warp yarns are real silk twisted yarns, and each twisted yarn contains two real silks. , The twists of the two silks before twisting are respectively 700-950 in Z or S twists / m, and the twisted yarn formed by the combination of two silks is 650-850 in S or Z twists / M, the raw material of the weft yarn is nylon, the front side of the fabric body 1 is provided with several pile blocks 2 and channels 3, and the back side is provided with a pile layer 4. Both the pile block 2 and the pile layer 4 are raised on the fabric body 1. The channels 3 are distributed around the pile block 2 and have the same width. The bronzing layer 5 is fixed on the front surface of the channel 3 by a hot melt adhesive layer 6.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap