Environment-friendly glue solution for LED full-color display, copper clad laminate and preparation method thereof

A display screen and environment-friendly technology, applied in chemical instruments and methods, circuit substrate materials, lamination, etc., can solve problems such as high energy consumption, achieve the effects of reducing product energy consumption, reducing usage, and improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Example 1

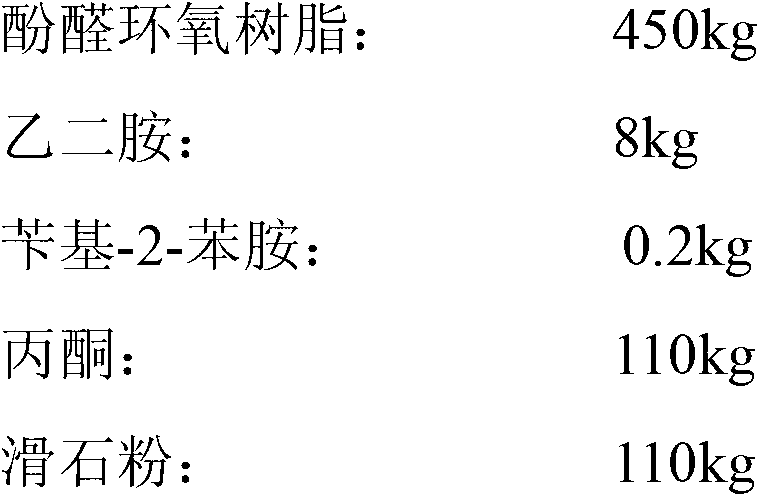

[0031] Raw material components of glue (parts by weight):

[0032]

[0033] Glue preparation method: mix ethylenediamine, benzyl-2-aniline and acetone, stir at 1000rpm for 4 hours; when it is completely dissolved, add phenolic epoxy resin, stir fully at 1200rpm for 3 hours After mixing uniformly, add talc powder, shear and disperse at a high speed of 3500 rpm for 45 minutes, then stir at a speed of 1200 rpm for 6 hours, and it will be fully matured.

[0034] The copper clad laminate is prepared by a manufacturing method commonly used in the field, and the process of gluing, lamination, pressing, disassembly, and processing is carried out in sequence.

[0035] Among them, the gluing process is: coating the electronic grade glass fiber cloth on the gluing machine with the above-prepared glue liquid, and drying it to form a gel to obtain a prepreg. The process parameters are: the oven temperature of the gluing machine is 170℃, the gluing speed is 12m / min, the mass per...

Example Embodiment

[0039] Example 2

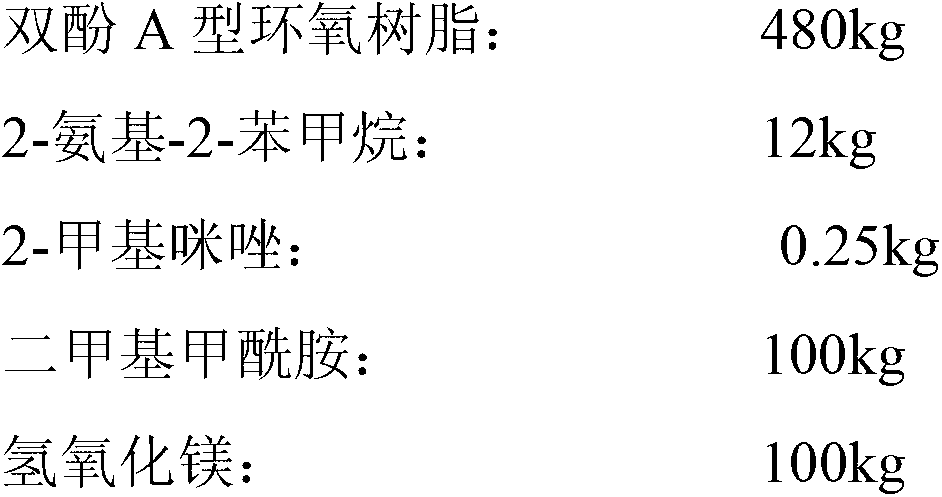

[0040] Raw material components of glue (parts by weight):

[0041]

[0042] Glue preparation method: mix 2-amino-2-phenylmethane, 2-methylimidazole and dimethylformamide, stir at 1500rpm for 2 hours; when it is completely dissolved, add bisphenol A ring The oxygen resin is fully stirred at 1000 rpm for 5 hours; after mixing is uniform, magnesium hydroxide is added, and high-speed shearing and dispersing at 5000 rpm for 30 minutes, and then stirred at 1500 rpm for 6 hours, and it is fully cured.

[0043] The copper clad laminate is prepared by a manufacturing method commonly used in the field, and the process of gluing, lamination, pressing, disassembly, and processing is carried out in sequence.

[0044] Among them, the gluing process is: coating the electronic grade glass fiber cloth on the gluing machine with the above-prepared glue liquid, and drying it to form a gel to obtain a prepreg. The process parameters are: the oven temperature of the gluing machine is 2...

Example Embodiment

[0048] Example 3

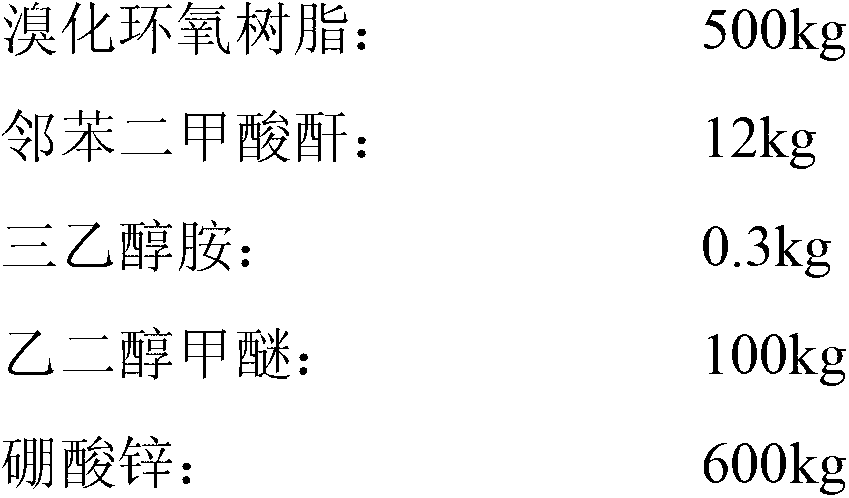

[0049] Raw material components of glue (parts by weight):

[0050]

[0051] Glue preparation method: mix phthalic anhydride, triethanolamine and ethylene glycol methyl ether, stir at 800 rpm for 3 hours; after it is completely dissolved, add brominated epoxy resin, and fully rotate at 1300 rpm Stir for 4 hours; after mixing uniformly, add zinc borate, disperse at high speed at 2500 rpm for 120 minutes, then stir at 1000 rpm for 8 hours, and it will be fully cured.

[0052] The copper clad laminate is prepared by a manufacturing method commonly used in the field, and the process of gluing, lamination, pressing, disassembly, and processing is carried out in sequence.

[0053] Among them, the gluing process is: coating the electronic grade glass fiber cloth on the gluing machine with the above-prepared glue liquid, and drying it to form a gel to obtain a prepreg. The process parameters are: the oven temperature of the gluing machine is 200℃, the gluing speed is 15m / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal stress | aaaaa | aaaaa |

| Flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap