Preparation method of thin ultrafine composite fiber artificial leather base cloth

A technology of ultra-fine fiber and artificial leather, applied in textiles and papermaking, etc., can solve the problems of too thin skeleton, difficult peeling, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

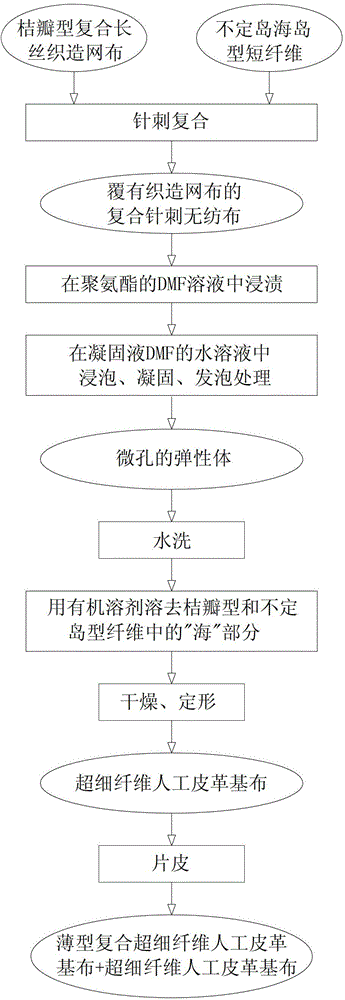

[0019] Such as image 3 Shown, the preparation method of this thin composite superfine fiber artificial leather base cloth may further comprise the steps:

[0020] (1) After combing and laying the web of Adventitia sea-island short fiber, it is laminated with Adventitia orange petal-shaped composite filament woven mesh. Cloth compounding to form a composite needle-punched non-woven fabric covered with a woven mesh cloth, and impregnate the composite needle-punched non-woven fabric in a DMF solution of polyurethane;

[0021] (2) Soak the semi-finished product obtained in step (1) in an aqueous solution of coagulation liquid DMF, carry out coagulation and foaming treatment, and polyurethane is made into an elastomer containing microcellular cells;

[0022] (3) washing with water;

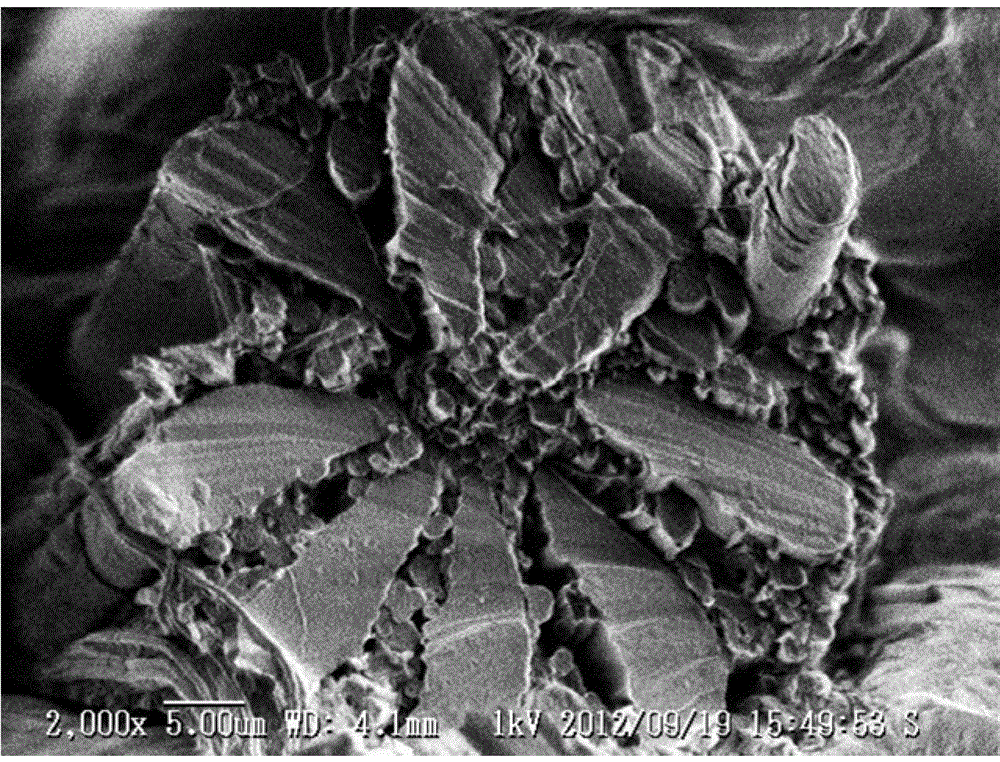

[0023] (4) Use toluene to dissolve the LDPE part of the adventitious island-in-the-sea short fiber and the adventitious island orange segment composite filament in the composite needle-punched nonwo...

Embodiment 1

[0037] Preparation of Garment Leather Base Fabric

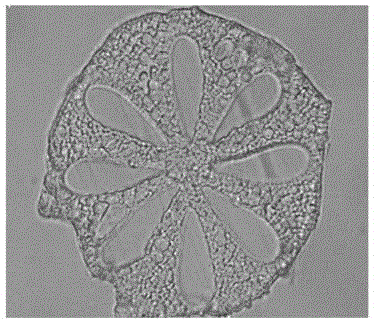

[0038] 1: Spinning process of PA6 / (PA6+LDPE) indeterminate island orange segment composite filament

[0039] (a) Raw material for spinning:

[0040] Piece-shaped component: PA6 chips, grade M32800, relative viscosity is 2.8η;;

[0041] Blend of LDPE+PA6: a blend of LDPE with a melt index of 50MFI and PA6 with a viscosity of 2.8η, wherein:

[0042] LDPE, grade MB9500, melt index is 50.

[0043] Nylon chips, grade M32800, relative viscosity is 2.8η;

[0044] (b) Raw material ratio: weight ratio: PA6 / (LDPE+PA6)=50 / (25+25)

[0045] (c) Spinneret specifications: number of holes × number of orange segments × aperture is 48 × (8+1) × 0.30mm;

[0046] (d) Screw extruder: specifications

[0047] (e) Metering pump specification: 0.6cc / rev;

[0048] (f) Cooling air temperature: 16°C, wind speed: 0.6m / s;

[0049] (g) Rotational speed of the oil pan: 26rpm / min, oil concentration: 3.0%;

[0050] (h) Spinning (winding) speed: 450...

Embodiment 2

[0070] Preparation of leather base cloth for automobiles

[0071] 1: Spinning process of PET / (PA6+LDPE) indeterminate island orange segment composite filament

[0072] (a) Raw material for spinning:

[0073] Piece-shaped component: PET chip, viscosity 0.64dl·g -1 ;

[0074] Blend of LDPE+PA6: a blend of LDPE with a melt index of 50MFI and PA6 with a viscosity of 2.8η, wherein:

[0075] LDPE, grade MB9500, melt index is 50, produced by Korean LG company.

[0076] Nylon chips, grade M32800, relative viscosity is 2.8η;

[0077] (b) Raw material ratio: weight ratio: PET / (LDPE+PA6)=60 / (20+20);

[0078] (c) Spinneret specifications: number of holes × number of orange segments × aperture is 48 × (8+1) × 0.30mm;

[0079] (d) Screw extruder: specifications

[0080] (e) Metering pump specification: 0.6cc / rev;

[0081] (f) Cooling air temperature: 18°C, wind speed: 0.6m / s;

[0082] (g) Rotational speed of the oil pan: 26rpm / min, oil concentration: 3.0%;

[0083] (h) Spinning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com