Method and apparatus for coating carrier

A coating and carrier technology, applied in the direction of surface coating liquid devices, chemical instruments and methods, coatings, etc., to achieve the effect of saving raw materials and increasing the duration of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

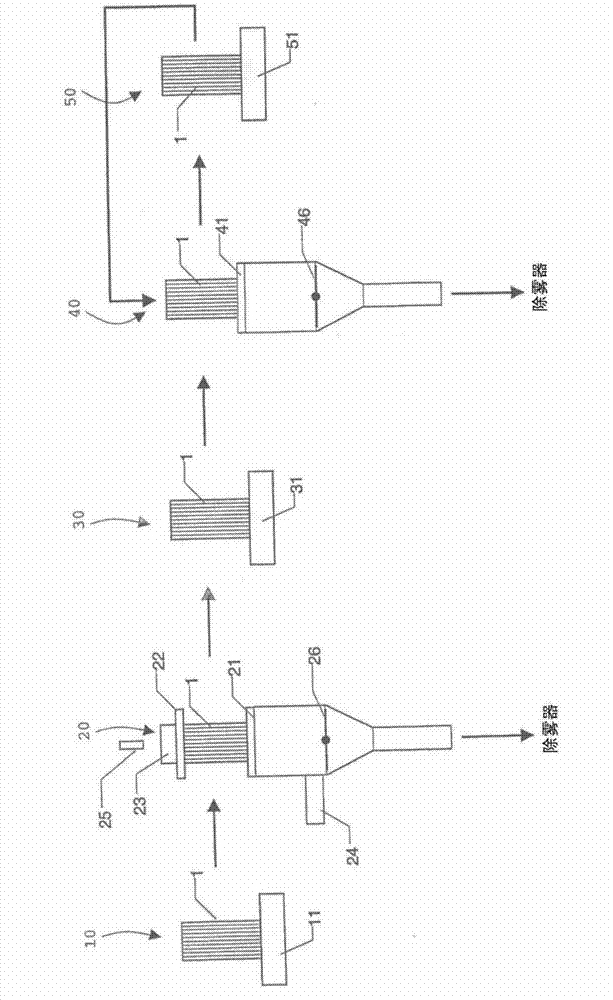

[0054] figure 1 Possible configurations of coating systems suitable for the present method are shown. Preferably, the coating system includes a coating station 20 for preparing a rough coating. For this, see figure 1 , the carrier 1 to be coated is placed on the holding element for this purpose. By inflating the inflatable rubber pad 21, the carrier 1 is fixed and sealed to the table. Furthermore, a second gasket 22 can be provided, which is placed on the upper end of the carrier 1 , so as to firmly fix the overflow 23 . Preferably, a height sensor 25 is arranged above it, which can detect the sufficient filling height of the carrier 1 and send a corresponding signal to the equipment controller or closing controller of the coating system.

[0055] To prepare the rough coating, the coating suspension is sucked into the carrier from the lower end through the feed tube 24 until the height sensor indicates that the specified filling height has been reached. Subsequently, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com