Anti-skidding control method for full hydraulic drive vehicle

A control method, full hydraulic technology, applied in the direction of fluid steering mechanism, etc., can solve the problems of slow response time and throttling loss, and achieve the effect of fast response speed and impact reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

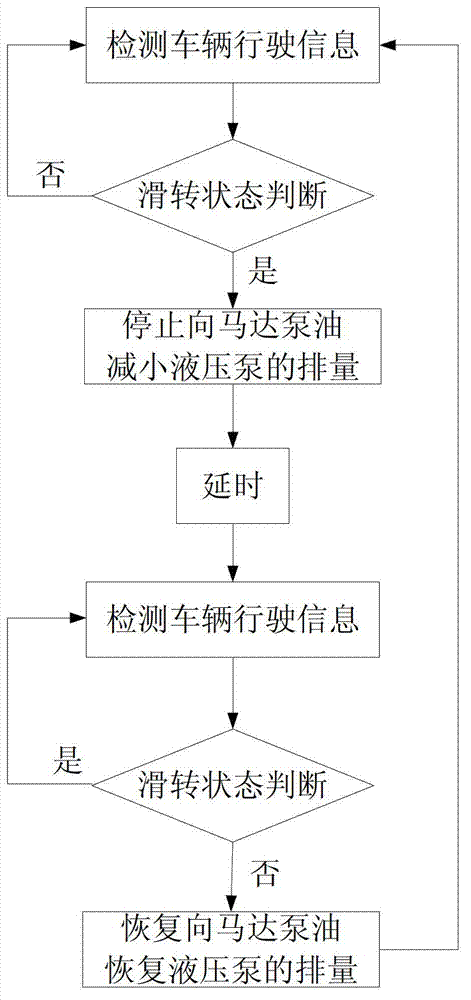

[0076] As an implementation manner, the judgment process in step 4 is specifically:

[0077] Calculate the third ratio of the speed of the slipping wheel and the speed of another wheel of the same shaft after the oil stop treatment;

[0078] Under the current rotation angle, it is judged whether the third ratio is in the preset interval; if so, it is judged that the wheel is out of the slipping state.

[0079] Further, the present invention can also compare the front and rear wheels. That is, for the left or right wheel, the wheel with the smallest speed is used as the benchmark; calculate the fourth ratio between the speed of the slipping wheel after oil stop processing and the benchmark; at the current corner, judge whether the fourth ratio is at the preset Set an interval; if so, it is judged that the wheel is out of the slipping state.

[0080] In step 5, after the oil pump is restored, the rotation speed of the hydraulic motor 2 can be coordinated with the rotation spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com