Novel fluorine-containing polybenzimidazole polymer, fluorinated organic diacid monomer as intermediate of the fluorine-containing polybenzimidazole polymer, and their preparation method

A technology of polybenzimidazole and benzimidazole, which is applied in the field of preparation of functional polymer materials, can solve problems that need to be further improved, strong intermolecular force, membrane oxidation degradation, etc., and is suitable for large-scale production and excellent oxidation resistance The effect of performance and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

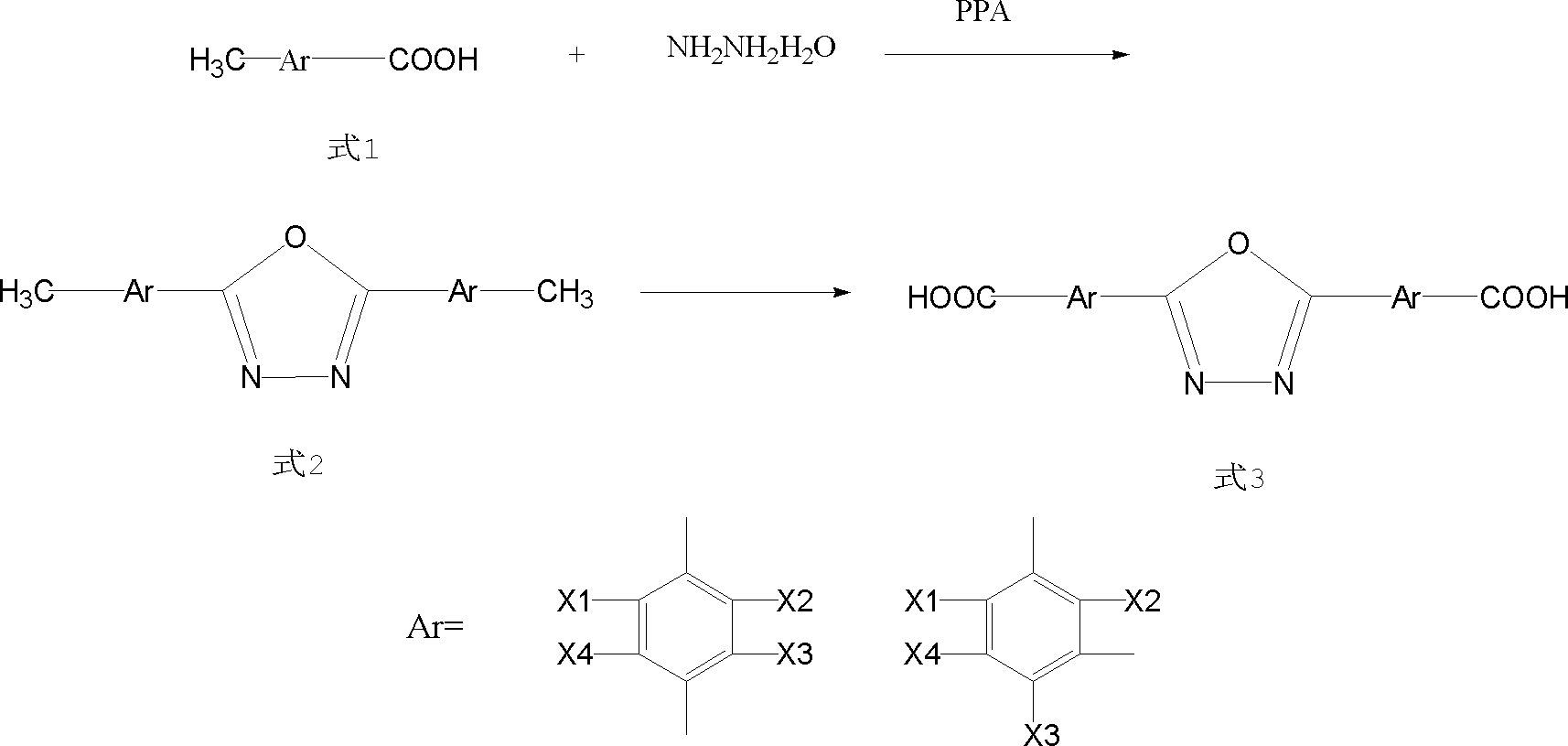

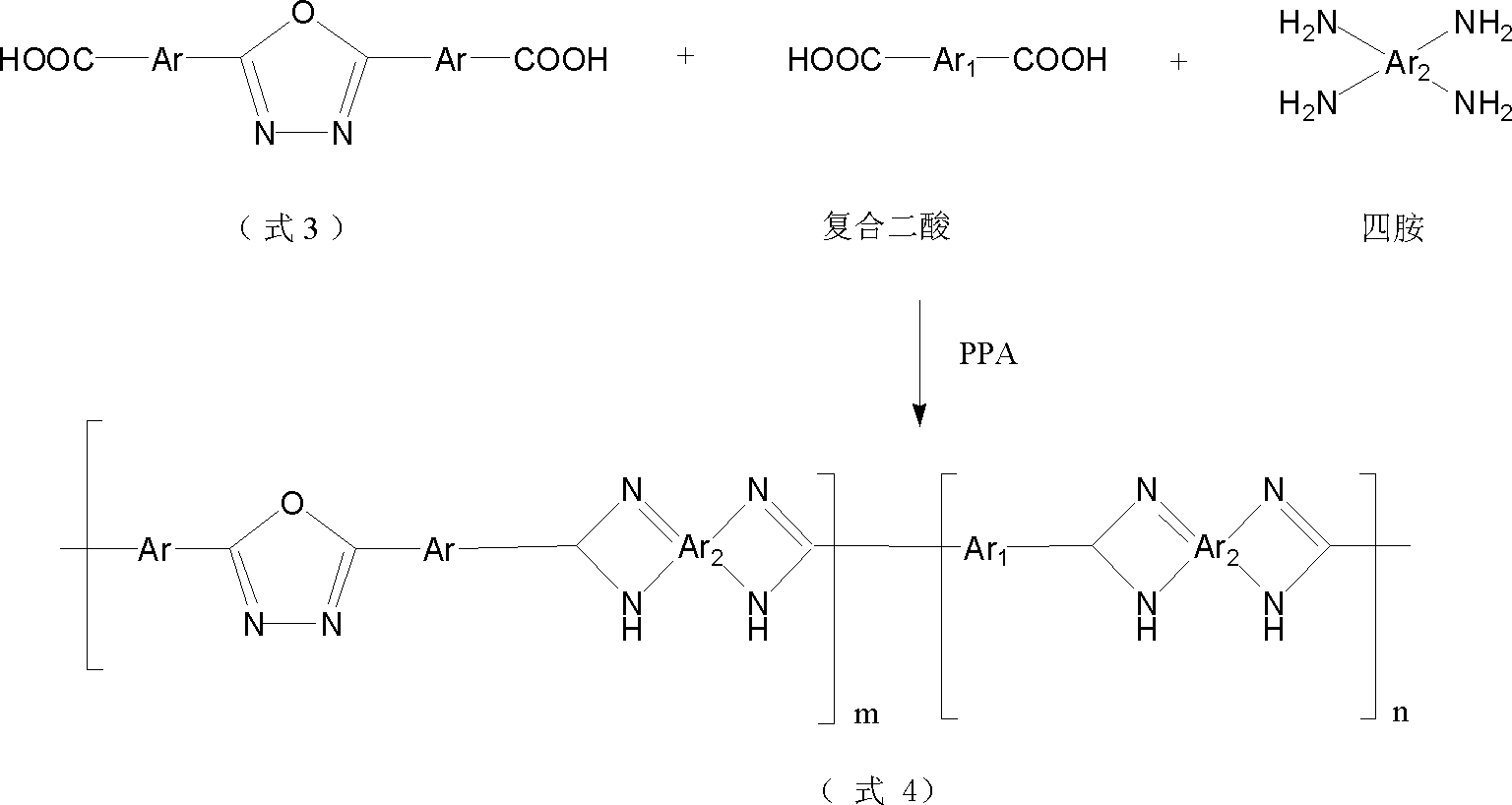

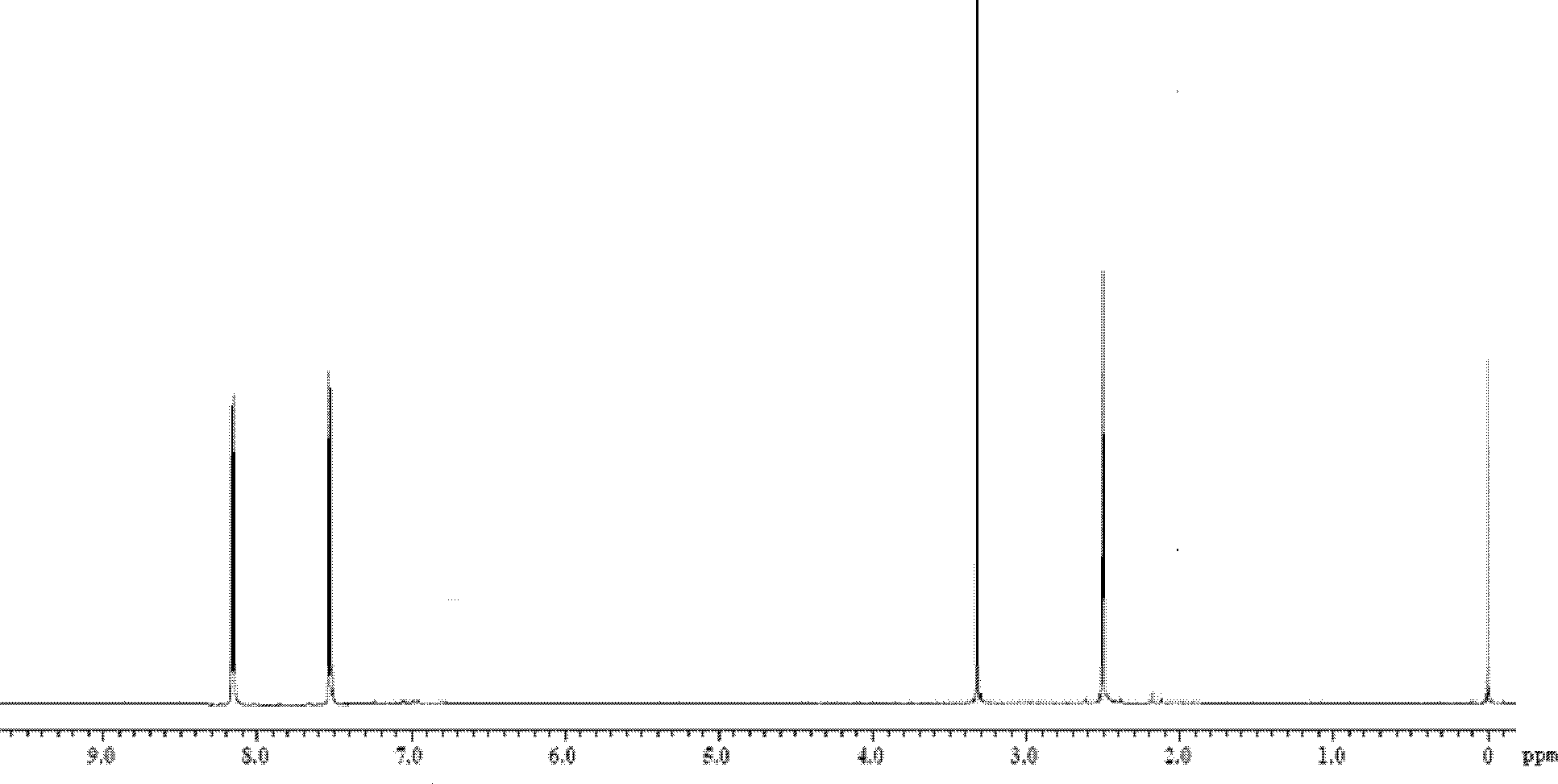

[0051] 1) Preparation of fluorinated organic diacid monomer

[0052] in N 2 Add 172g of 2,3-difluoro-4 methylbenzoic acid, 25g of hydrazine hydrate, and 750g of polyphosphoric acid into the three-necked flask under protection (the molar ratio of the three is 2:1:15), start stirring, and slowly heat to 60°C for reaction. After 3 hours, the temperature was raised to 120°C for 8 hours. The reaction mixture was poured into 5 L of water, and the white precipitate was collected by filtration. The precipitate was neutralized with 1% NaOH aqueous solution, washed with water until neutral, and dried in vacuum to obtain 182 g of white intermediate 2. 5-bis(2,3-difluoro-4methylphenyl)oxadiazole. Take 32.2g (0.1mol) of this intermediate and add it to a 2L three-necked flask, then add 40g of water and 100g of pyridine, heat to reflux, slowly add potassium permanganate in portions, add 47.4g (0.3mol), and reflux for 100h. The mixture was poured into 10% hydrochloric acid with excess mass ...

Embodiment 2

[0058] 1) Preparation of fluorinated organic diacid monomer

[0059] in N 2 Add 114g of 2,3,5,6-tetrafluoro-4-methylbenzoic acid, 12.5g of hydrazine monohydrate, and 380g of polyphosphoric acid into the three-necked flask under protection (the molar ratio of the three is 2.2:1:15), and open Stir, slowly heat to 80 ° C for 3 h, heat up to 200 ° C for 24 h, pour the reaction mixture into 3 L of water, filter and collect the white precipitate, and dissolve the resulting precipitate with a mass concentration of 1% Na 2 CO 3 After the aqueous solution was neutralized, it was washed with water until neutral, and dried in vacuum to obtain 116 g of white intermediate 2,5-bis(2,3,5,6-tetrafluoro-4methylphenyl)oxadiazole. Add 39.4g (0.1mol) of the obtained intermediate into a 2L three-necked flask, then add 100g of water and 100g of pyridine, heat to reflux, slowly add potassium permanganate in portions, add 63g (0.4mol), and react under reflux for 20h. The substance was poured into ...

Embodiment 3

[0065] 1) Preparation of fluorinated organic diacid monomer

[0066] Add 218g of 2,3,4,6-tetrafluoro-5-methylbenzoic acid, 25g of hydrazine monohydrate, and 260g of polyphosphoric acid into the there-necked flask under the protection of argon (the molar ratio of the three is 2.1:1:5) , start stirring, slowly heat up to 80°C for 4h, heat up to 200°C for 16h, pour the reaction mixture into 3L of water, collect the precipitate by filtration, and remove the resulting precipitate with a mass concentration of 1% Na 2 CO 3 The aqueous solution was neutralized, washed with water until neutral, and dried in vacuum to obtain 197 g of white intermediate (2,3,4,6-tetrafluoro-5-methylphenyl)oxadiazole. Take 39.4g (0.1mol) of this intermediate and add it to a 2L three-necked flask, then add 120g of water and 60g of pyridine, heat to reflux, slowly add potassium permanganate in portions, add 158g (1.0mol), and react under reflux for 2h. Poured into excess mass concentration of 10% hydrochl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com