Engine cam assembly, engine brake device and automobile

A technology of engine and cam, which is applied in the direction of engine components, valve driving devices, machines/engines, etc., can solve the problems of cumbersome engine control system, complex arrangement of engine valve mechanism, and increased cost of exhaust brake system, and achieve simple and reliable structure , The increase in engine cost is small, and the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The cam assembly in this embodiment is suitable for four-stroke internal combustion engines.

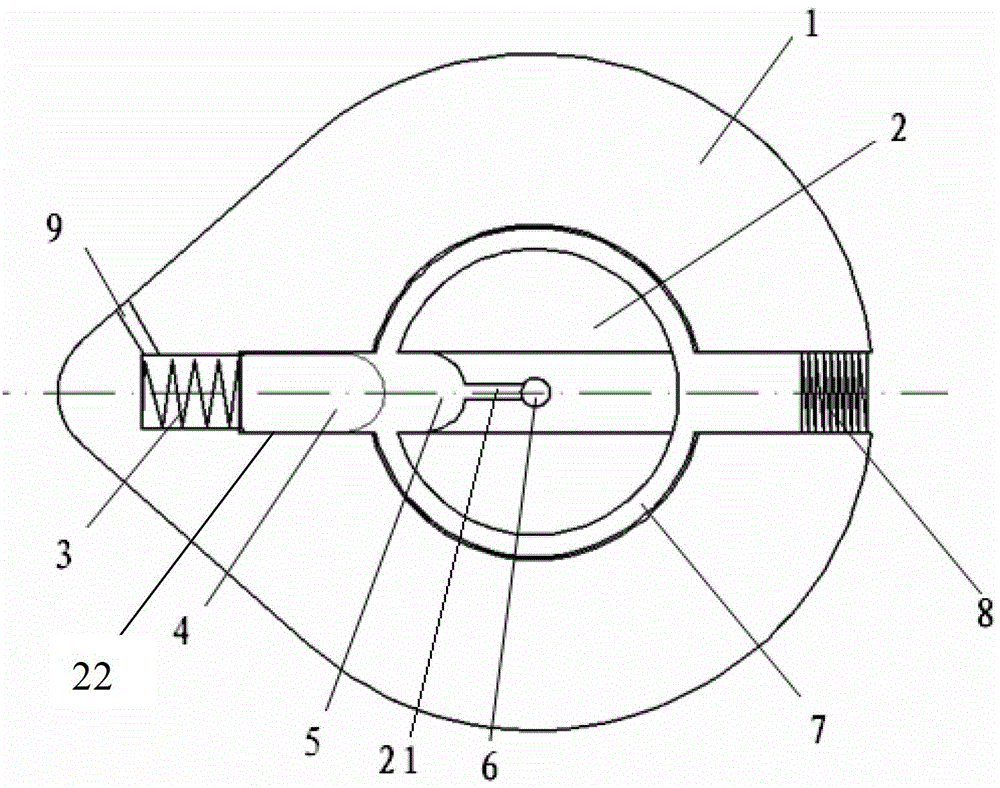

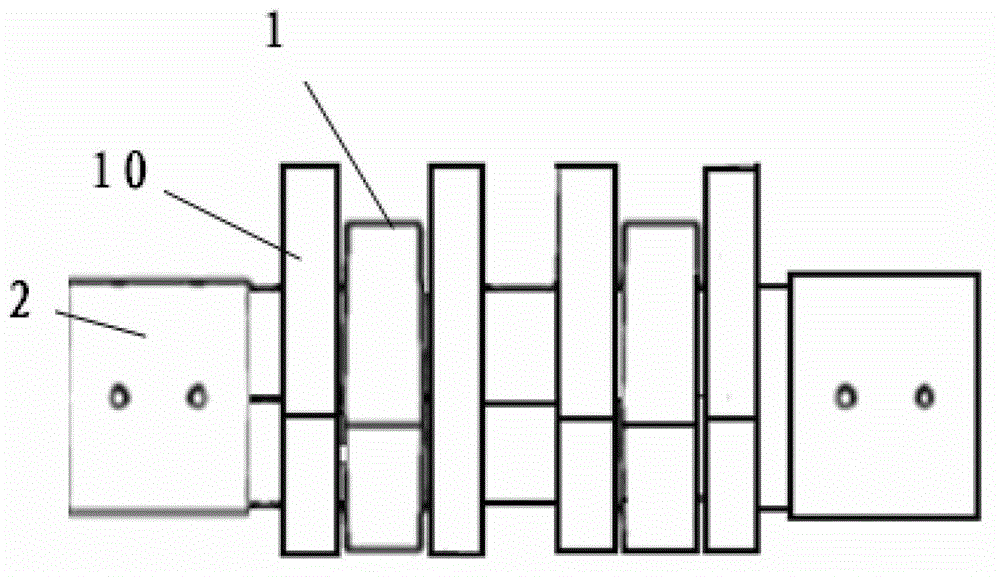

[0032] like figure 2 As shown, in this embodiment, the cam assembly includes a camshaft 2, a first cam 10, a second cam 1 and a connecting structure.

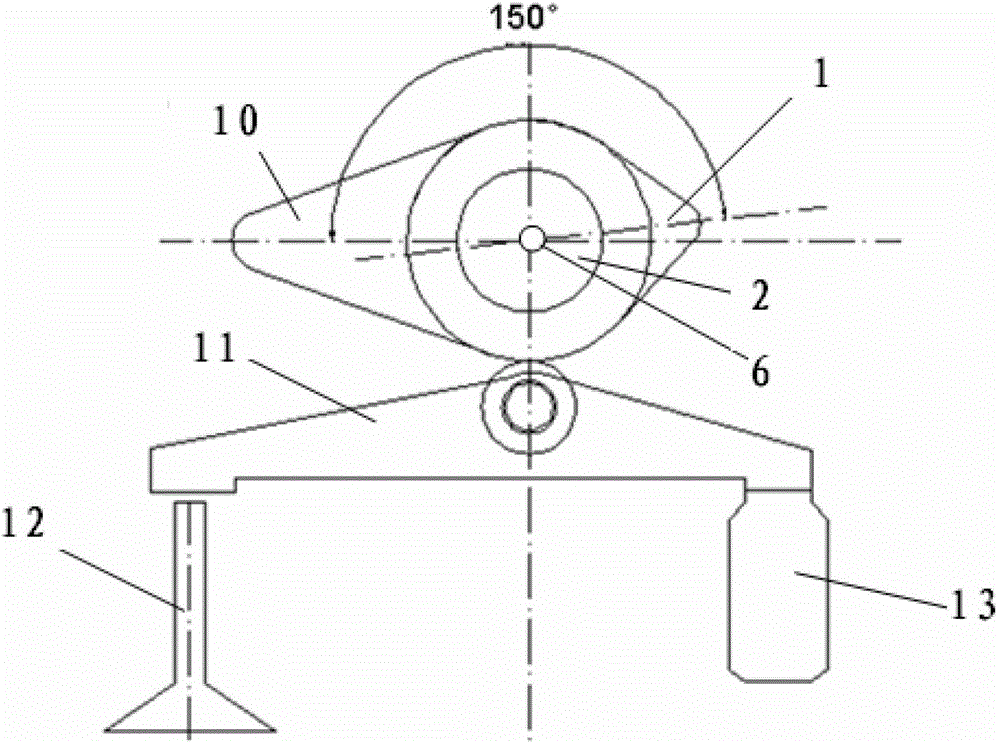

[0033] Wherein, the first cam 10 is fixedly installed on the camshaft 2, and the first cam 10 is used for exhausting when the engine is running normally, and the camshaft 2 drives the first cam 10 to rotate to control the opening and closing of the exhaust valve in the engine. The second cam 1 is sleeved on the camshaft 2, and the diameter of the inner hole of the second cam 1 is larger than the outer diameter of the camshaft 2, so the second cam 1 does not rotate with the camshaft 2 when the engine is running normally. , the connecting mechanism can connect the second cam 1 and the camshaft 10 as a whole, and the camshaft 10 drives the second cam 1 to rotate to control the opening and closing of the exhaust valve 12 .

[00...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that the accommodating hole 22 is not provided at the tip of the second cam 1 , and the base circle radii of the first cam 10 and the second cam 1 are not equal.

[0058] Other structures of the cam assembly in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0060] The difference between this embodiment and Embodiment 1 is: preferably, the cam assembly may further include a reset mechanism, and the reset mechanism is used to reset the second cam when the second cam is not connected to the camshaft 2 . Therefore, the precision when the second cam 1 works can be further ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com