Preparation method of Nb3AL superconducting wire split conductor precursor

A technology of superconducting wires and precursors, applied in the usage of superconducting elements, superconducting/high-conducting conductors, cable/conductor manufacturing, etc., can solve the problems of difficult to remove Al particles, demanding manufacturing equipment, etc., and achieve scale-up The effect of production, excellent performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example 1

[0027] Nb 3 The preparation method of Al superconducting wire rod multi-core wire precursor includes the following steps:

[0028] The first step is to prepare the composite bar

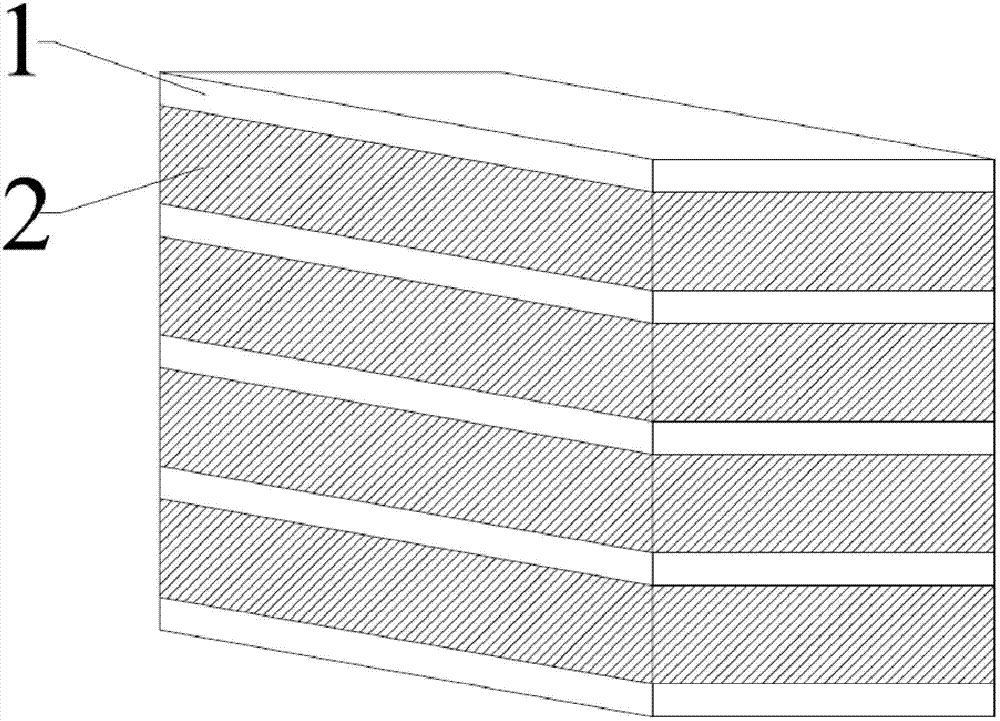

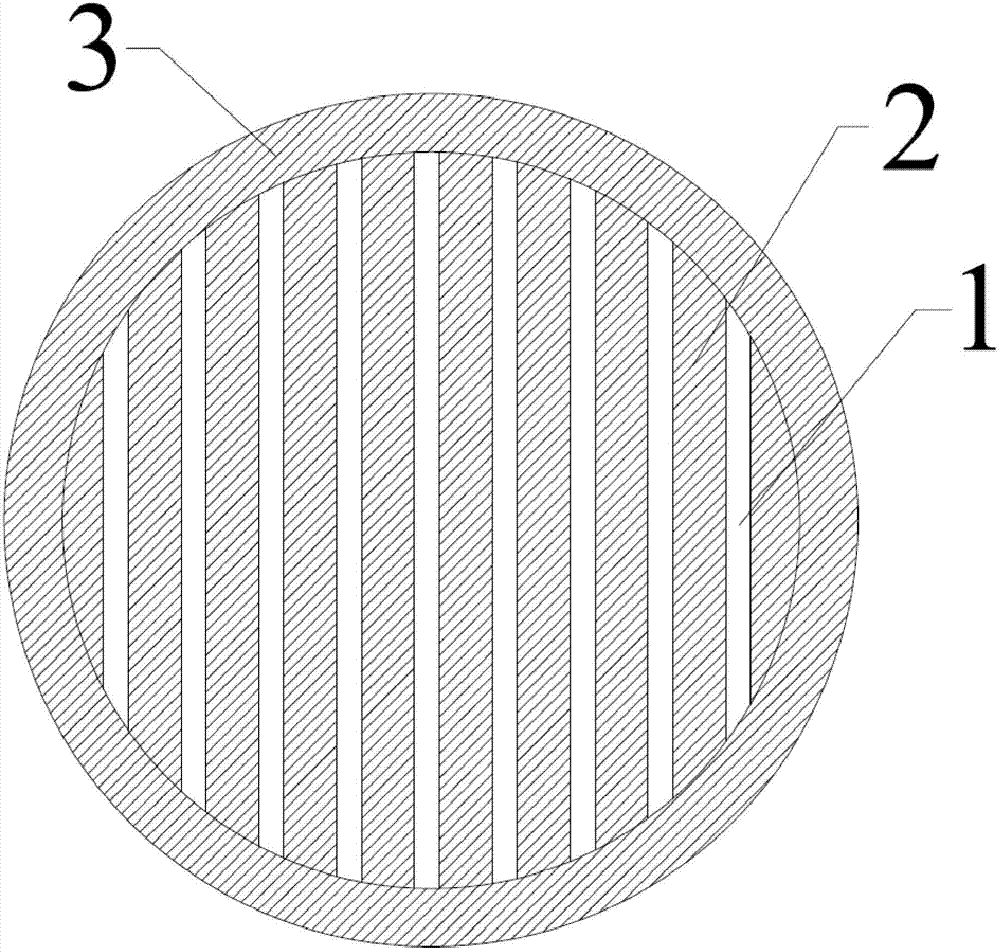

[0029] Take multiple Nb sheets with the same shape and thickness, and then take multiple Al sheets with the same shape and thickness. The shape of the Nb sheet and the Al sheet are the same, and the thickness ratio is 3:1. The Nb sheet and Al sheets are interlaced to form figure 1 The composite sheet shown is then cut along the normal direction of the non-adhesive surface of the composite sheet, and the track of the cutting line is circular to form a cylindrical composite sheet, and then the cylindrical composite sheet is packed into the inner diameter In the Nb tube adapted to the outer diameter of the cylindrical composite sheet, the figure 2 The composite bar shown;

[0030] The second step is to prepare Nb 3 Al superconducting wire single core wire precursor

[0031] The composite bar...

Example Embodiment

[0035] Example 2

[0036] Nb 3 The preparation method of Al superconducting wire rod multi-core wire precursor includes the following steps:

[0037] The first step is to prepare the composite bar

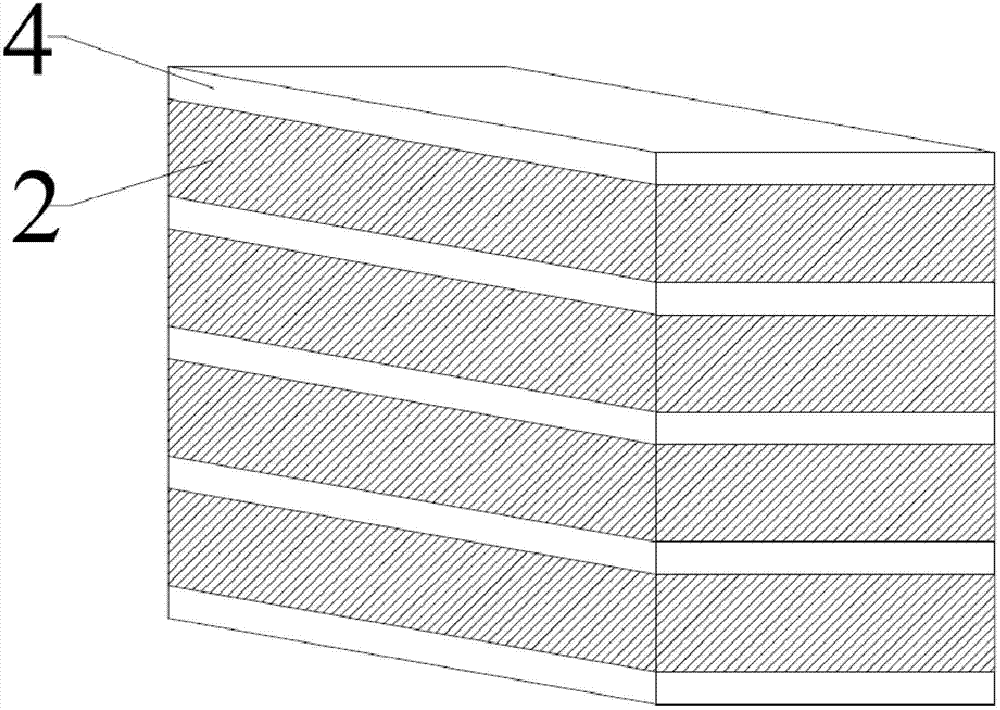

[0038] Take multiple Nb sheets with the same shape and thickness, and then take multiple Al-Mg alloy sheets with the same shape and thickness, where Mg accounts for 2% of the total mass of the Al-Mg alloy, and Al accounts for Al -The mass parts of the total Mg alloy is 98%, the shape of the Nb sheet and the Al-Mg alloy sheet are the same, and the thickness ratio is 3:1. The Nb sheet and the Al-Mg sheet are interlaced together to form a image 3 The composite sheet shown is then cut along the normal direction of the non-adhesive surface of the composite sheet, and the track of the cutting line is circular to form a cylindrical composite sheet, and then the cylindrical composite sheet is packed into the inner diameter In the Nb tube adapted to the outer diameter of the cylindrical composit...

Example Embodiment

[0044] Example 3

[0045] Nb 3 The preparation method of Al superconducting wire rod multi-core wire precursor includes the following steps:

[0046] The first step is to prepare the composite bar

[0047] Take multiple Nb sheets with the same shape and thickness, and then take multiple Al-Mg alloy sheets with the same shape and the same thickness, where Mg accounts for 5% of the total mass of Al-Mg alloy, and Al accounts for Al -The mass parts of the total Mg alloy is 95%, the shape of the Nb sheet and the Al-Mg alloy sheet are the same, the thickness ratio is 3:1, the Nb sheet and the Al-Mg sheet are interlaced together to form image 3 The composite sheet shown is then cut along the normal direction of the non-adhesive surface of the composite sheet, and the track of the cutting line is circular to form a cylindrical composite sheet, and then the cylindrical composite sheet is packed into the inner diameter In the Nb tube adapted to the outer diameter of the cylindrical composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap