Thermoforming units for heat-resistant containers

A heat-resistant container and thermoforming technology, applied in containers, rigid containers, packaging, etc., can solve problems such as deformation and low heat resistance, and achieve the effect of compact thermoforming device and restraint of capital investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

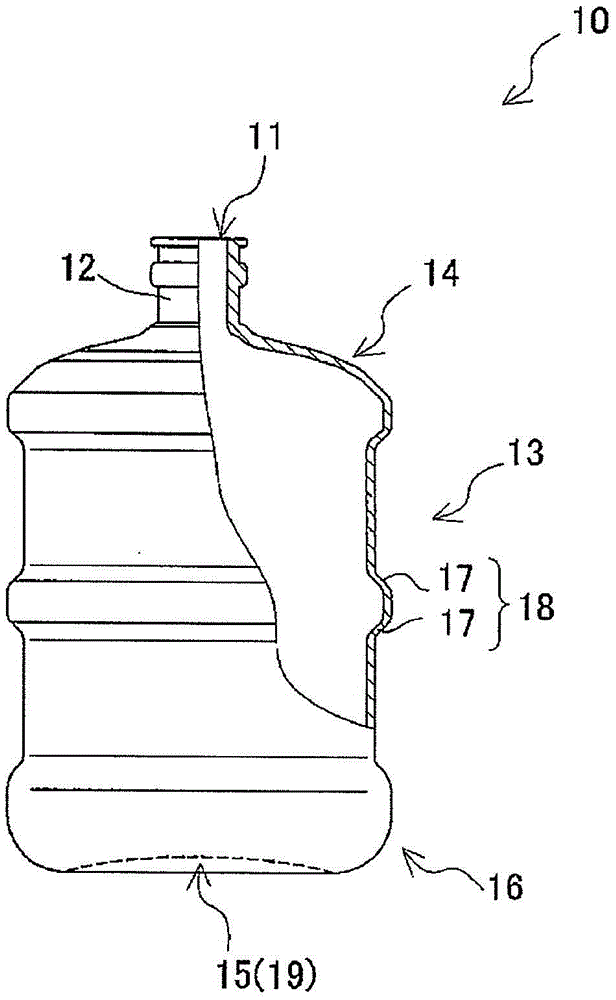

[0061] figure 1 The heat-resistant container 10 shown in is formed of polyethylene terephthalate (PET) resin and is used, for example, as a container with about 3 to 5 gallons (about 12 to 20 liters) for mineral water. Recycle the bottle. The heat-resistant container 10 as a large recyclable container includes: a neck portion 12 having, for example, an outer diameter of about 40 mm to 60 mm and including an opening 11 at an upper end; a cylindrical body portion 13 having, for example, about 270 mm to 300 mm shoulder portion 14, which connects neck portion 12 and body portion 13 and gradually expands from neck portion 12; bottom portion 15, which seals one end of body portion 13; and heel portion 16, which connects body portion 13 with bottom part 15.

[0062] The main body portion 13 is formed with a reinforcing portion 18 constituted by a plurality of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com