Conveyor synchronous cleaning device

A cleaning device and conveyor technology, applied in the field of conveyors, can solve problems such as long cleaning time, and achieve the effects of simple structure, convenient maintenance, and avoidance of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

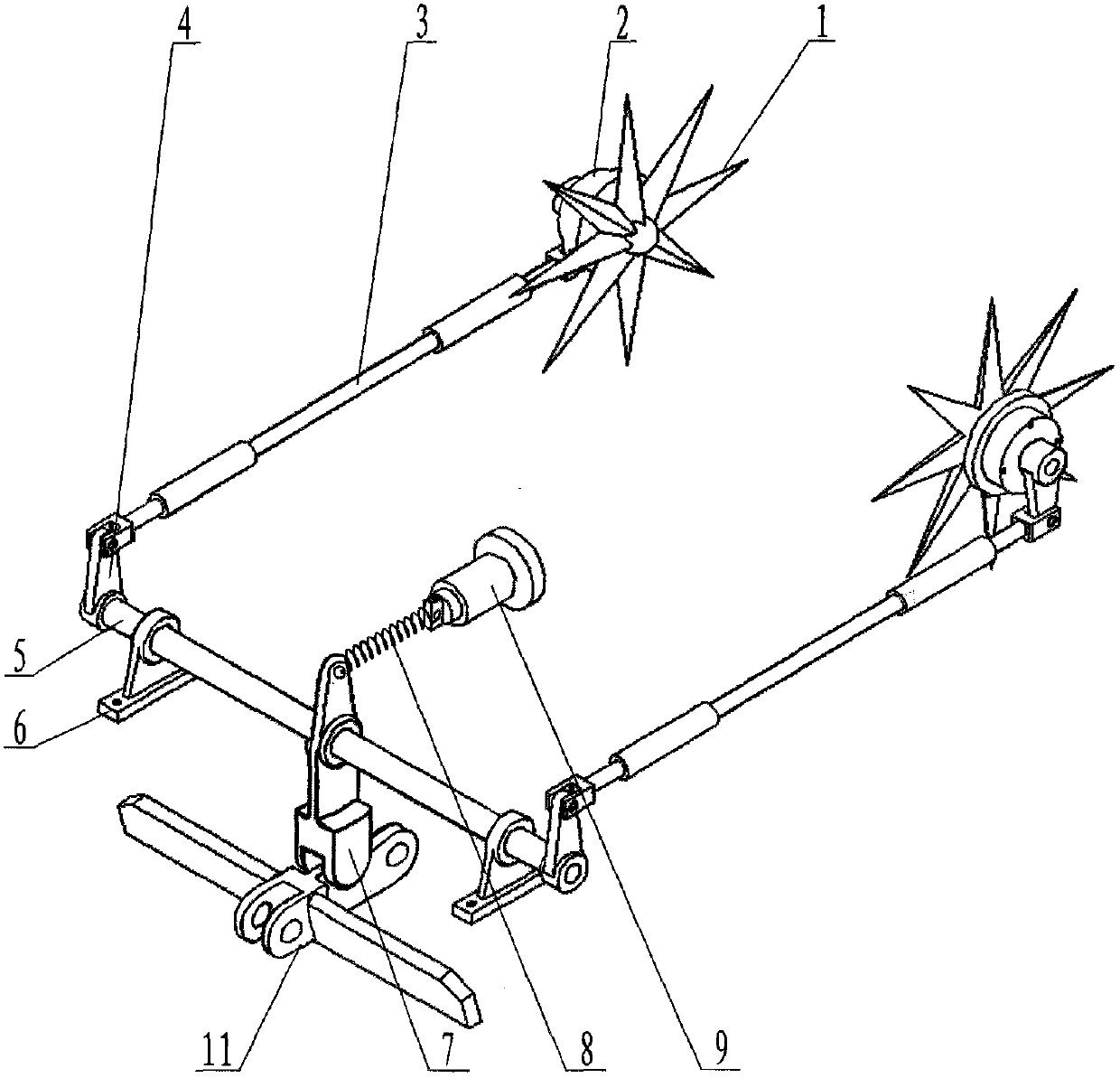

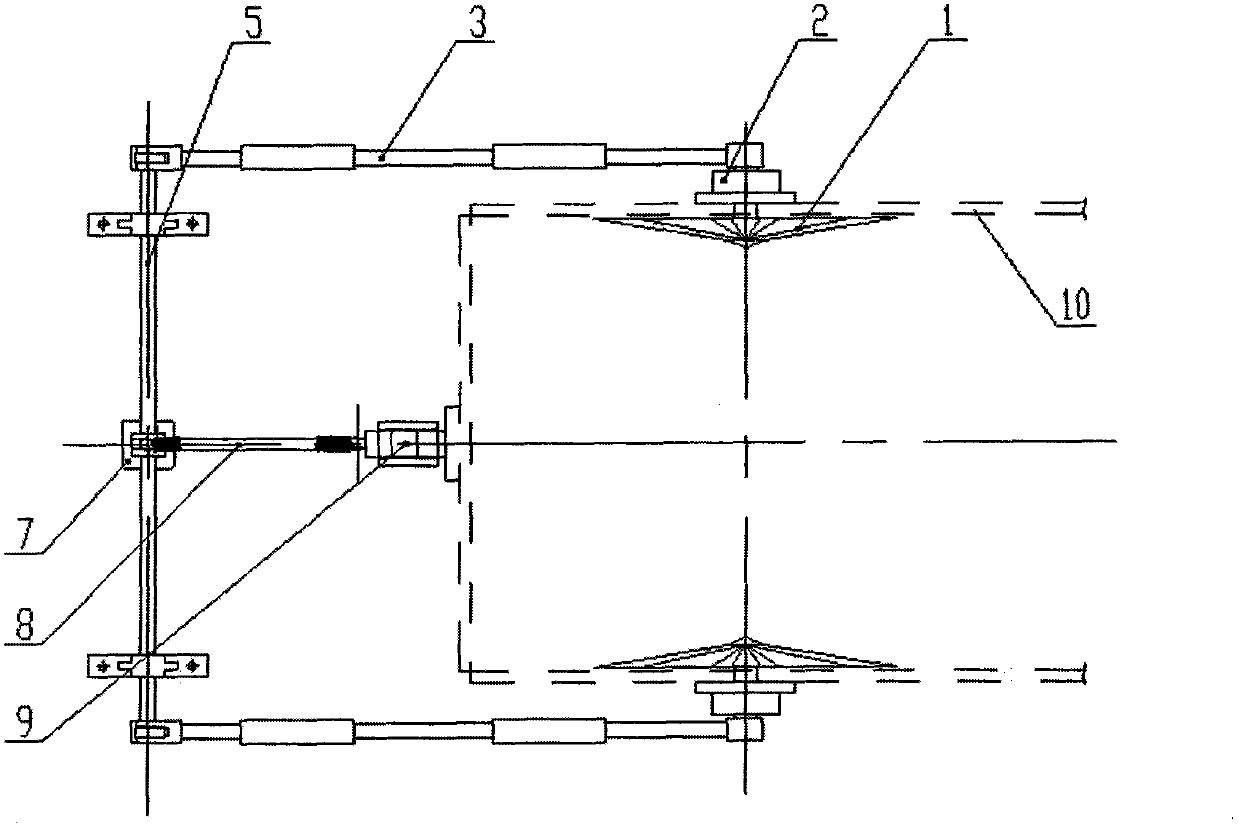

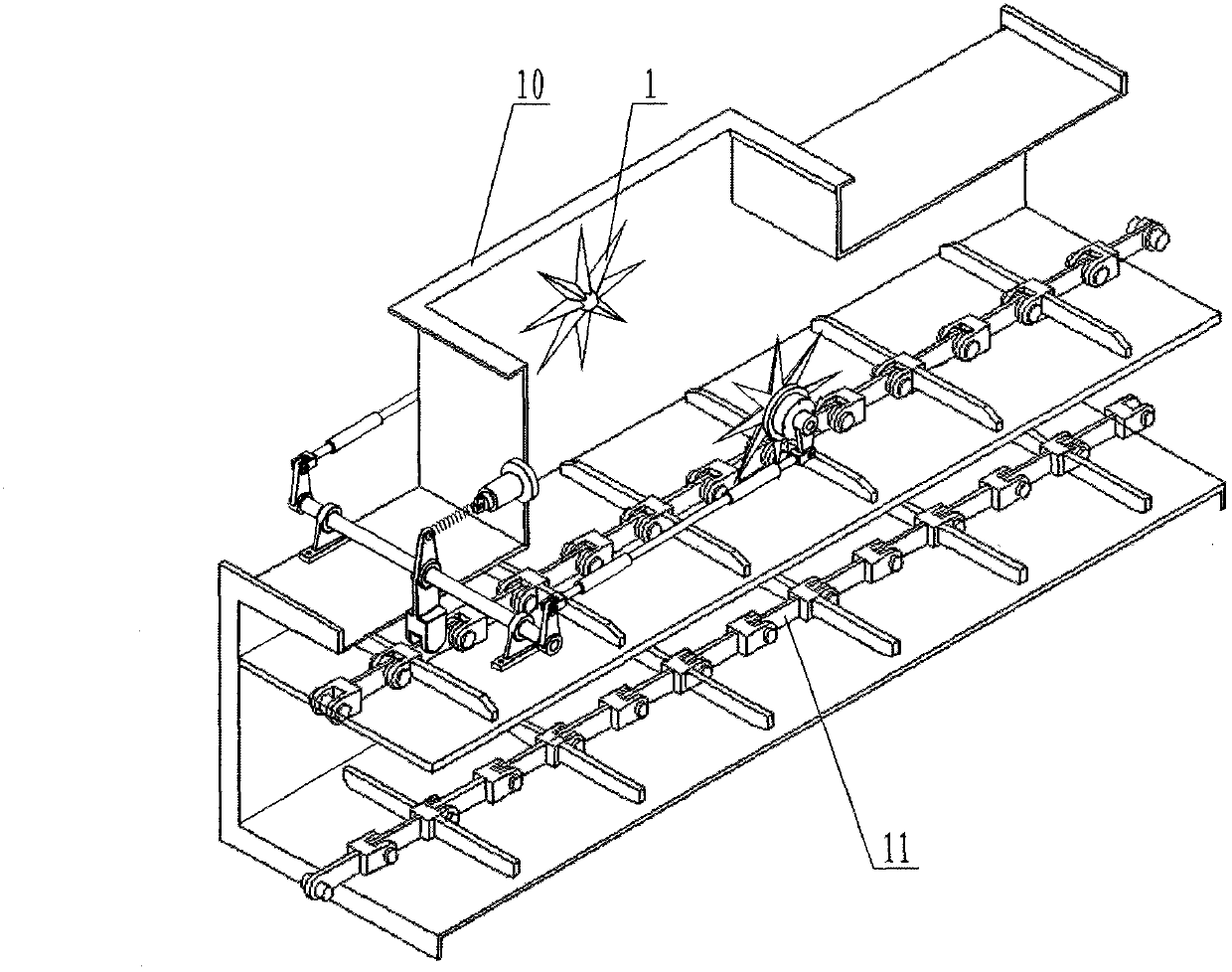

[0010] by figure 1 It can be seen that the synchronous cleaning device of the conveyor of the present invention includes two star-shaped triangular scrapers 1 arranged in the housing of the feed inlet, two one-way bearing seats 2 and two adjustable connecting rods 3 arranged on the outside of the housing. And two connecting rods 4, two star-shaped triangular scrapers 1 are respectively connected to the one-way bearing seat 2 installed on the side of the housing, and one end of the adjustable connecting rod 3 on this side is connected to the one-way bearing seat on this side. 2. The other end is connected to the connecting rod 4 on this side. The two connecting rods 4 are respectively installed on both sides of the shaft 5. The shaft 5 is fixed on the upper part of the casing through the shaft seat 6. The lower part of the rod 7 is provided with a groove for contact with the chain, and the upper part of the shift rod 7 is connected to an adjustable support 9 fixed on the casing t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap