Semi-automatic constant-temperature melt trough

A melting tank, semi-automatic technology, applied in chemical instruments and methods, chemical/physical processes, heat treatment, etc., can solve the problems of steam waste, high cost, volatilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

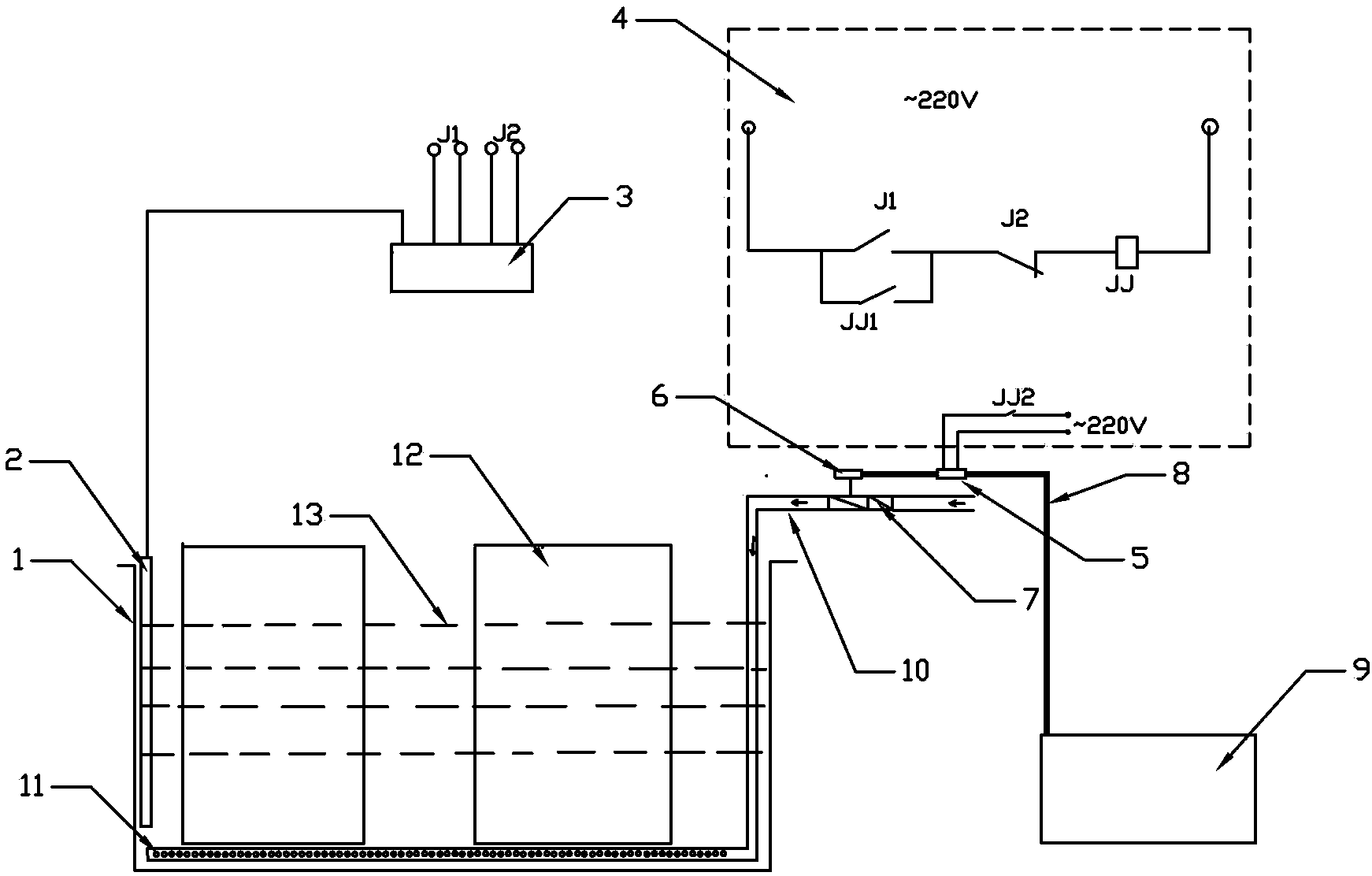

[0008] figure 1 The shown semi-automatic thermostatic melt tank consists of melt tank 1, temperature measuring resistor 2, temperature measuring instrument 3, pneumatic solenoid valve control circuit 4, pneumatic solenoid valve 5, pneumatic steam valve 6, manual steam regulating valve 7, air pipe 8, air Compressor 9, steam pipe 10, steam pipe small hole 11, composed of steam pipe 10 entering the melt tank 1 from above the melt tank 1, steam pipe small hole 11 is opened on the steam pipe 10 at the bottom of the melt tank 1, The steam pipeline 10 outside the melt tank 1 is provided with a pneumatic steam valve 6 and a manual steam regulating valve 7, the pneumatic steam valve 6 is connected to the air pipe 8, the other end of the air pipe 8 is connected to the air compressor 9, and the air pipe 8 is connected to the pneumatic solenoid valve 5, The temperature measuring resistor 2 is placed inside the melt tank 1 , the temperature measuring resistor 2 is connected with the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com