Manufacturing method of thick-wall high-drum annular forging

A manufacturing method and ring forging technology, applied in metal rolling and other directions, can solve the problems of low press precision, large forging allowance, and low production efficiency, and achieve uniform and stable structure and performance, reduce forging allowance, and improve the structure and performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method for manufacturing thick-walled high-tube annular forgings of the present invention will be described in detail below in conjunction with the accompanying drawings.

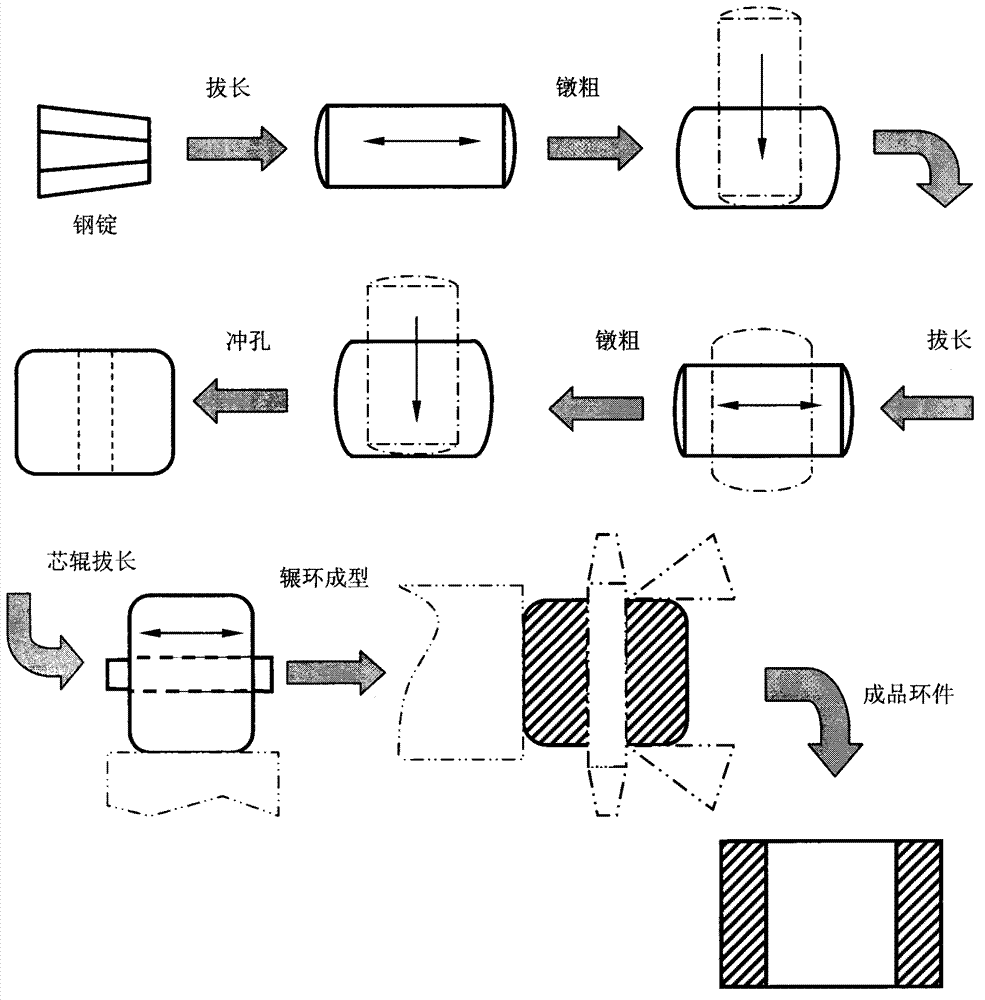

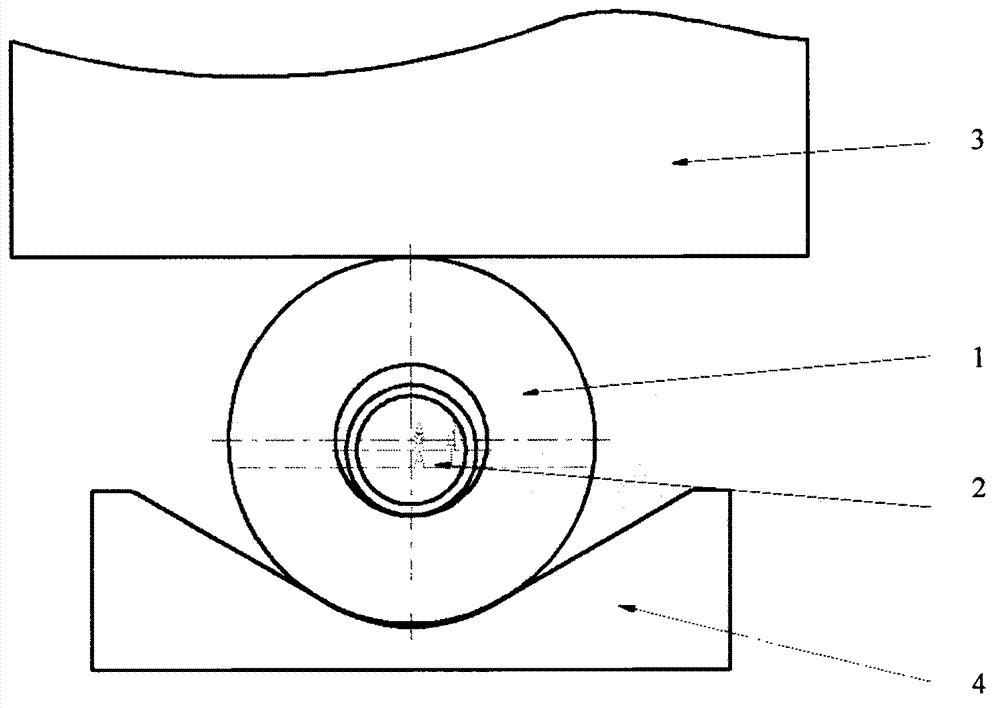

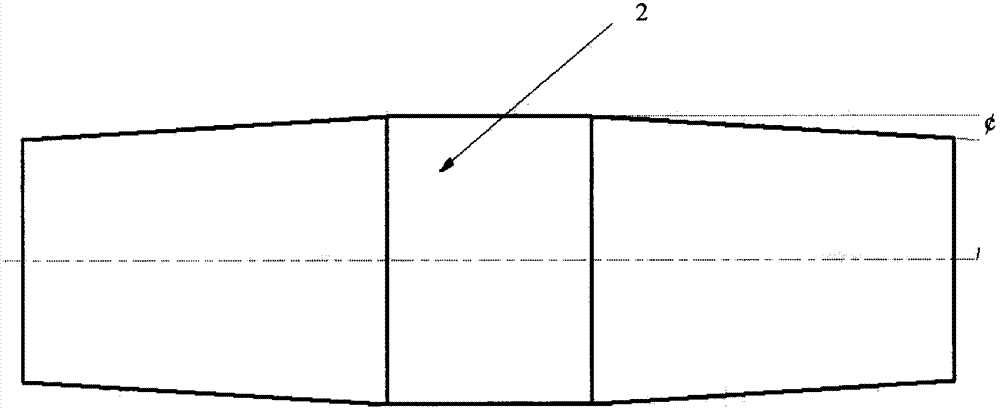

[0029] Such as figure 1 As shown, firstly, the blank 1 (the blank in the figure is a steel ingot) is drawn axially on the press; then the blank 1 is upset radially on the press, and then drawn axially, and then Radial upsetting, so that the casting structure of the billet 1 is improved, and the grains are refined; then a long mandrel is used to punch a hole in the center of the billet 1; and the billet 1 is elongated in the axial direction, while using Elongate the core roller 2 to expand the inner hole; finally, the product is formed by simultaneous radial and axial rolling on the ring rolling machine.

[0030] Preferably, the forging ratio of elongation and upset in the step a and step b is in the range of 3-5.

[0031] Preferably, in the step d, the surface of the long mandrel is sprayed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com