Sector filter disc

A filter disc, fan-shaped technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of increased energy consumption, large filter resistance, poor water permeability, etc., and achieve the effect of cost saving and use efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

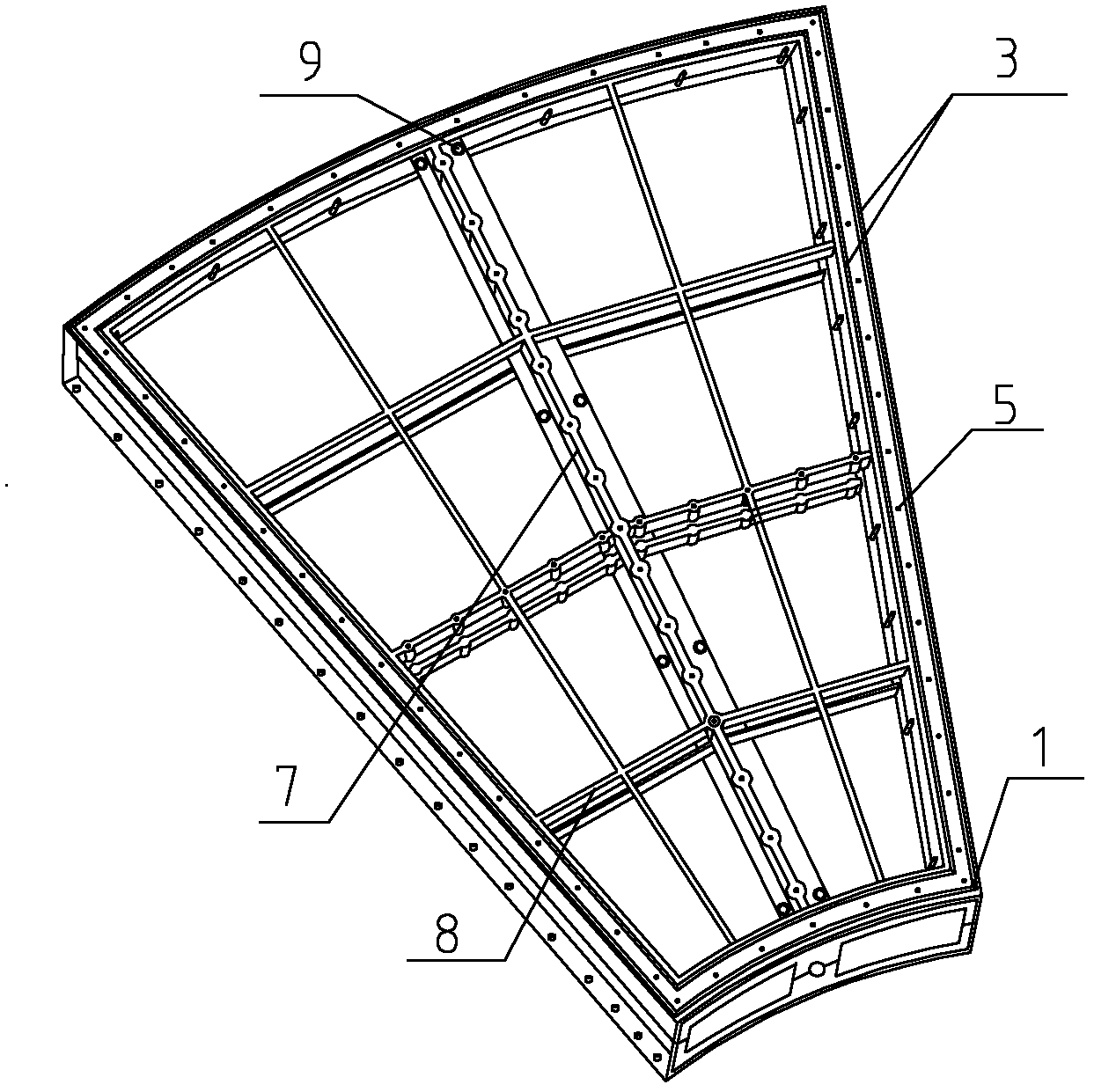

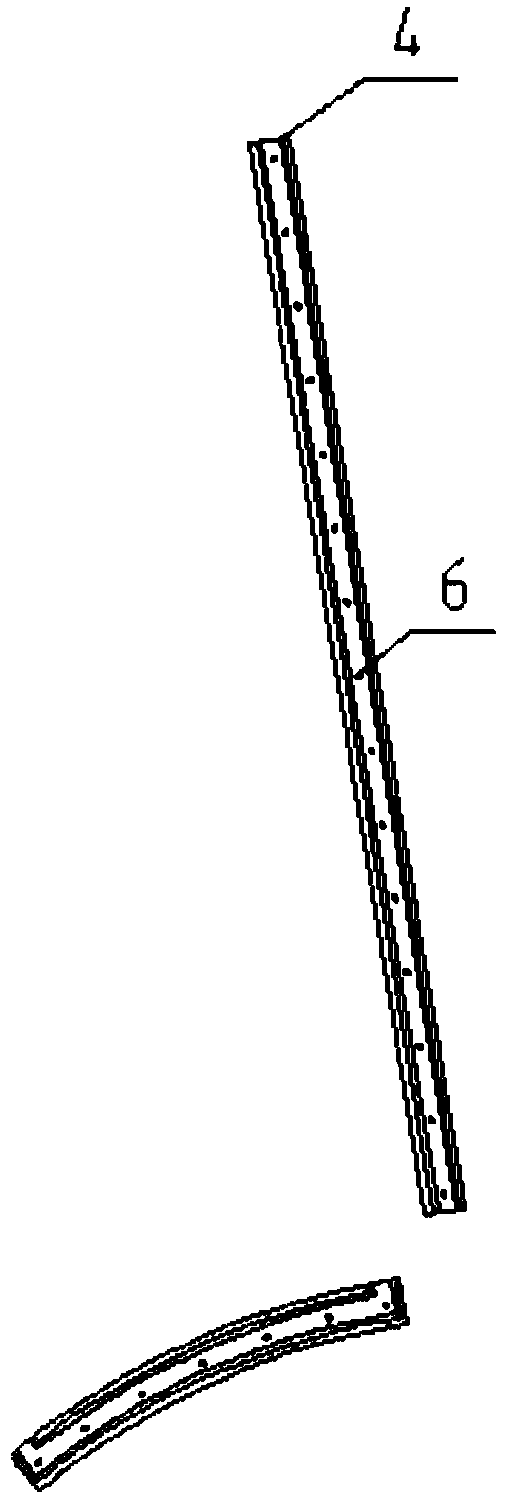

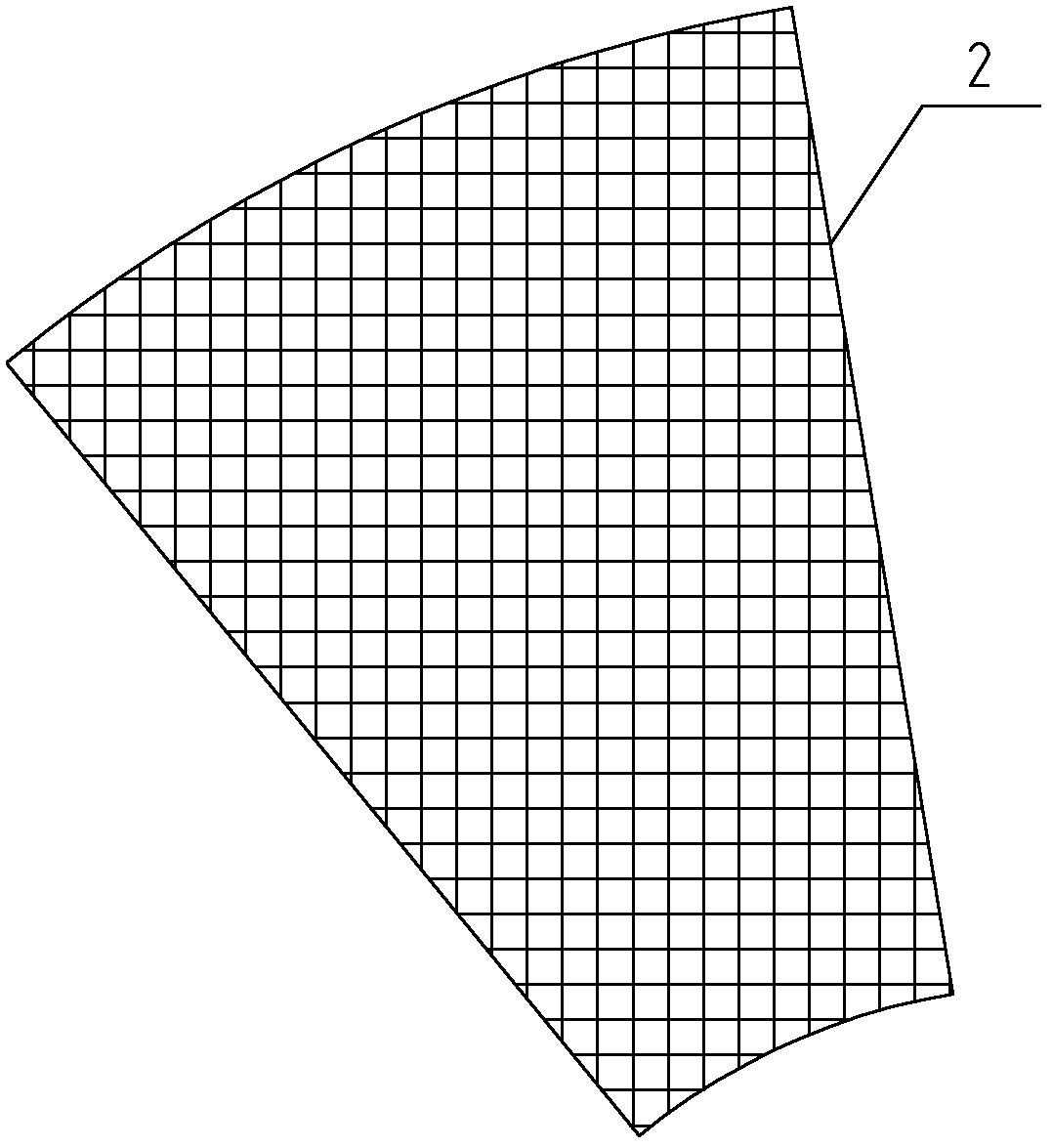

[0010] Such as figure 1 , figure 2 , image 3 As shown, the fan-shaped filter disc includes a plastic frame 1 and a filter screen 2, and a filter cloth pressing groove 3 is provided on the edge of the plastic frame 1, and the filter screen 2 passes through the filter cloth pressing groove. 3 The matching convex plastic bead 4 of the filter screen is pressed and connected; the plastic frame 1 is fixed and tightly connected by a bolt structure; a bead screw hole 5 is provided in the middle of the filter cloth pressing groove 3, and a bead screw hole 5 is provided on the filter cloth Corresponding screw holes 6 are also provided on the convex plastic bead 4; the middle of the plastic frame 1 is composed of a filter disc support 7 and a filter disc reinforcement rib 8, and the filter disc support 7 is provided with a filter disc support combination connection hole 9 . The filter frame 1 of the present invention is a plastic frame, which saves cost, and the filter cloth 2 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com