Multistage pore silica nano material and preparation method thereof

A technology of silica and nanomaterials, applied in the field of material science, which can solve the problems of small specific surface area and underdeveloped pore structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

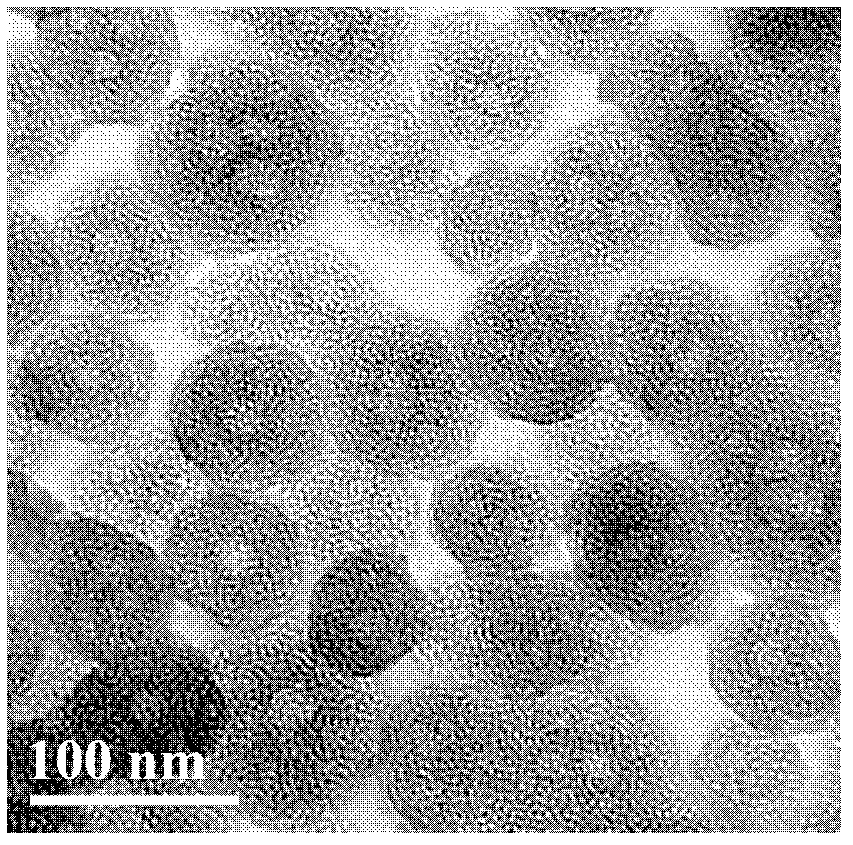

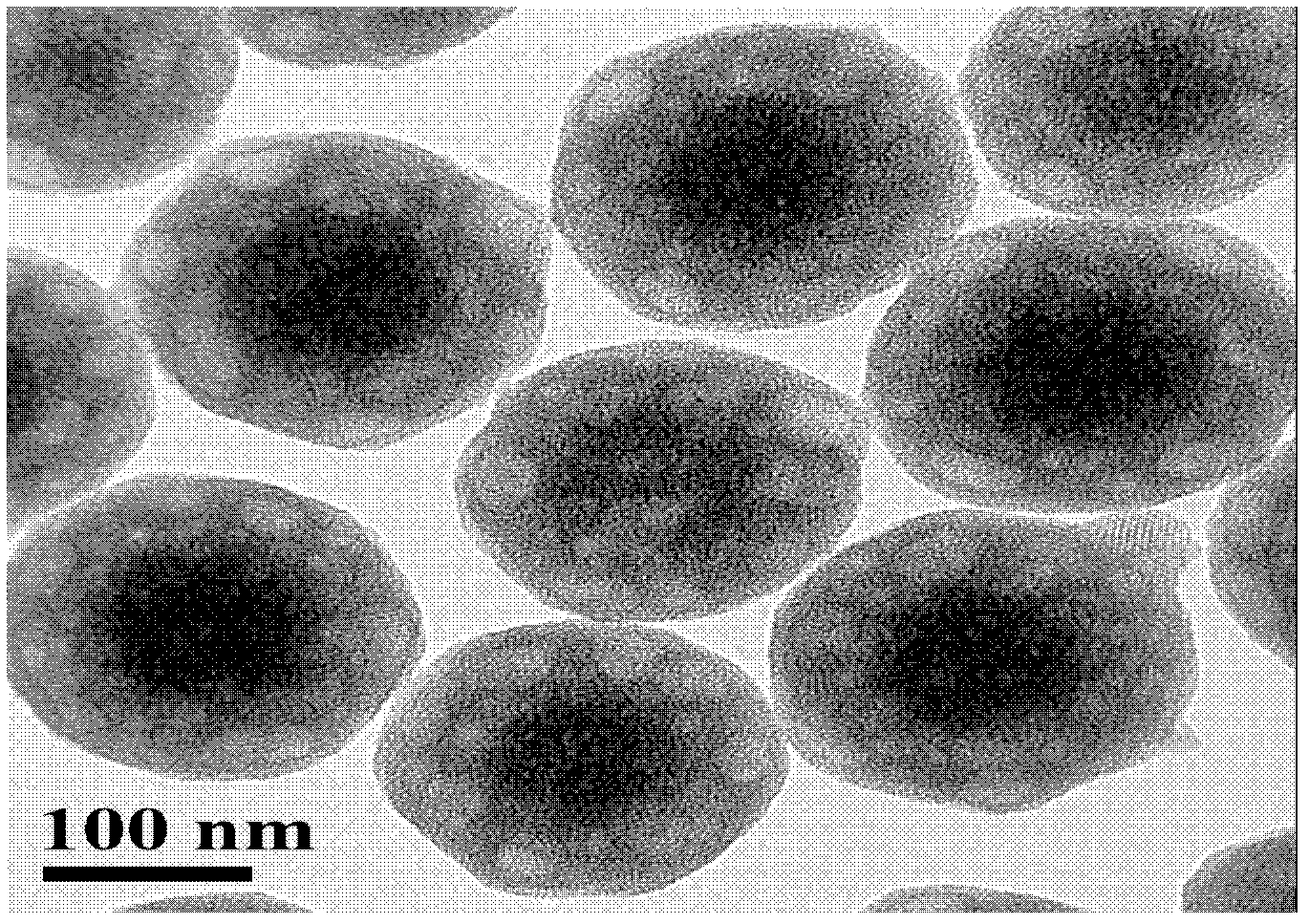

[0019] Dissolve 20mg of polyvinylpyrrolidone (molecular weight: 38000) in 100ml of absolute ethanol, add 20ml of deionized water, 3g of ammonia water, and 1.5g of tetraethylsilicate, stir at room temperature for 14 hours, and centrifuge to separate silica colloidal particles. It was dispersed in 20 ml of deionized water. Another 0.29 g of cetyltrimethylammonium bromide was dissolved in 30 ml of deionized water, 3 g of ammonia water was added, mixed with the above colloidal silica particle solution, and stirred at room temperature for 0.5 h. The entire reaction mixture was moved into a stainless steel autoclave with a polytetrafluoroethylene liner, treated at 100°C for 24 hours, centrifuged to separate the solid product, dried, and roasted at 550°C for 6 hours to obtain a multi-stage vesicle-shaped channel located in the center of the particle. Silica nanomaterials.

Embodiment 2

[0021] Dissolve 40mg of polyvinylpyrrolidone (molecular weight: 38000) in 100ml of absolute ethanol, add 20ml of deionized water, 3g of ammonia water, and 1.5g of tetraethylsilicate, stir at room temperature for 14 hours, and centrifuge to separate colloidal silica particles. It was dispersed in 20 ml of deionized water. Another 0.29 g of cetyltrimethylammonium bromide was dissolved in 30 ml of deionized water, 3 g of ammonia water was added, mixed with the above colloidal silica particle solution, and stirred at room temperature for 0.5 h. The entire reaction mixture was moved into a stainless steel autoclave with a polytetrafluoroethylene liner, treated at 100°C for 24 hours, centrifuged to separate the solid product, dried, and roasted at 550°C for 6 hours to obtain a multi-stage vesicle-shaped channel located in the center of the particle. Silica nanomaterials.

Embodiment 3

[0023] Take 20mg of polyvinylpyrrolidone (molecular weight 58000) and dissolve it in 100ml of absolute ethanol, add 20ml of deionized water, 3g of ammonia water, and 1.5g of tetraethylsilicate, stir at room temperature for 14 hours, and centrifuge to separate silica colloidal particles. It was dispersed in 20 ml of deionized water. Another 0.29 g of cetyltrimethylammonium bromide was dissolved in 30 ml of deionized water, 3 g of ammonia water was added, mixed with the above colloidal silica particle solution, and stirred at room temperature for 0.5 h. The entire reaction mixture was moved into a stainless steel autoclave with a polytetrafluoroethylene liner, treated at 100°C for 24 hours, centrifuged to separate the solid product, dried, and roasted at 550°C for 6 hours to obtain a multi-stage vesicle-shaped channel located in the center of the particle. Silica nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com