Method for picking beams of beam lifting and carrying machine for railway bridging

A technology of lifting and transporting beams, taking beams and transporting beams, is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., and can solve the problems of high beam installation costs, high platform foundation requirements, and low construction efficiency. , to achieve huge economic and social benefits, improve construction efficiency, and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

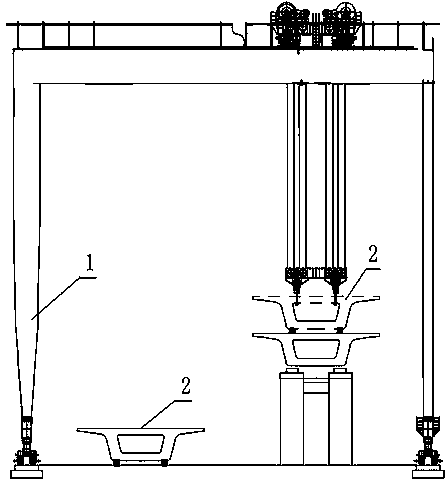

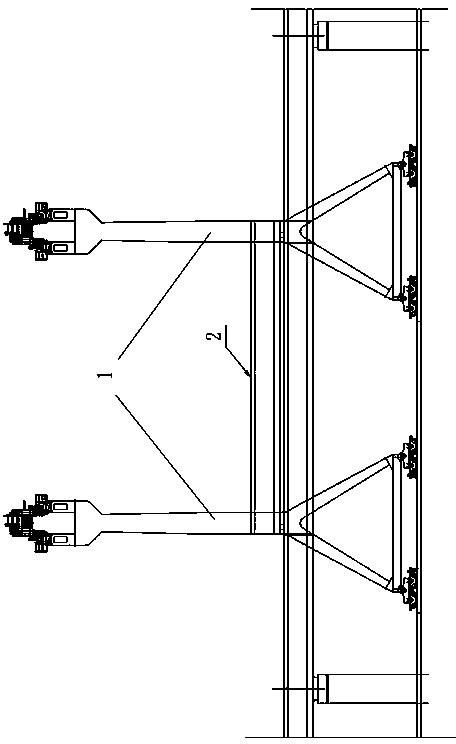

[0019] According to the accompanying drawings, the specific process of hoisting the box girder on the railway bridge deck:

[0020] 2.1 The box girder to be erected is under the two 450-ton beam lifting machines, and the basin-type rubber bearing is installed on the lifting beam platform. After passing the inspection, the box girder to be erected is lifted to the bridge deck platform by two 450-ton beam lifting machines.

[0021] 2.2 The front running wheels of the lifting beam machine run to 30 cm from the end of the box girder to be erected and stop.

[0022] 2.3 When the lifting height of the beam lifting machine is limited

[0023] 2.3.1 The two girder lifting machines lift the girder lifting machine synchronously until the running wheel distance of the girder lifting machine is 50 cm from the bridge deck (the lowest point of the running wheel is higher than the top surface of the pre-embedded steel bars on the bridge deck) and stops.

[0024] 2.3.2 The crane girders of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com